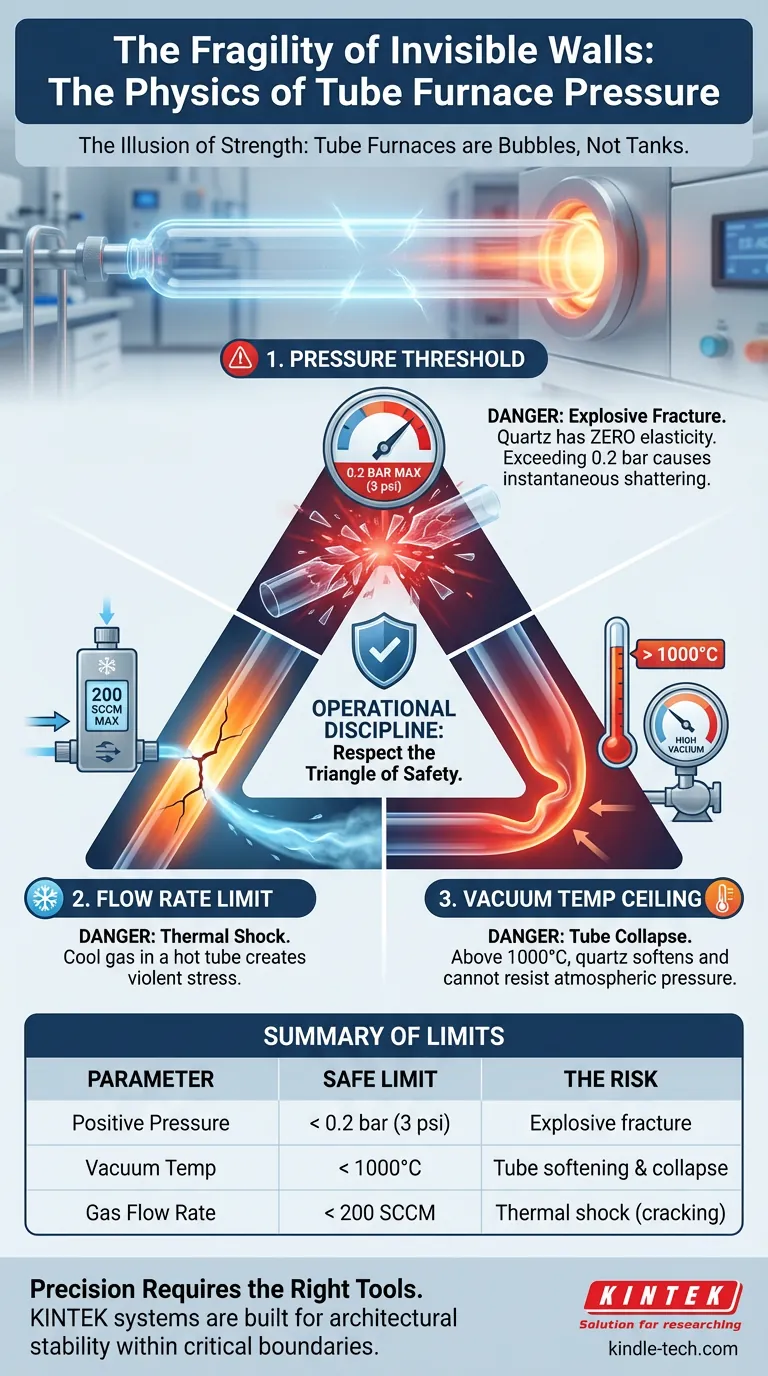

The Illusion of Strength

In the laboratory, we are often lulled into a false sense of security by the materials around us. Stainless steel, heavy ceramics, and thick glass feel invincible. We assume they can handle whatever stress we apply, provided we don't drop them.

But in the world of thermal processing, strength is relative.

A tube furnace is a marvel of engineering, capable of reaching blistering temperatures. Yet, physically, it is remarkably delicate. It is not a tank; it is a bubble.

Most failures in tube furnaces do not come from age or defect. They come from a misunderstanding of a single, invisible force: Pressure.

The 0.2 Bar Threshold

The most dangerous assumption a researcher can make is treating a tube furnace like a pressure vessel. It is not.

It is a controlled-atmosphere device.

Standard quartz tubes are designed to operate under a vacuum or very low positive pressure. The red line is distinct and unforgiving: 0.2 bars (3 psi or 0.02 MPa).

Why is the limit so low?

- Geometry: The tubular shape handles radial stress well, but it is not built to contain expanding force.

- Material: Quartz is a brittle ceramic. It has zero elasticity. When internal pressure exceeds the tensile strength of the glass, it doesn't bulge. It shatters.

Pushing beyond 0.2 bars is not "testing the limits." It is inviting structural failure.

The Geometry of Failure: Thermal Shock

Pressure is not just about bars and pascals. It is also about the aggressive movement of molecules.

Quartz is chosen for these furnaces because of its thermal stability. It can endure heat that would melt common metals. However, it has an "Achilles' heel": Thermal Shock.

This usually happens when we get impatient.

Introducing a high flow rate of cool process gas into a hot tube creates a violent temperature differential. The inside of the glass cools instantly while the outside remains hot. The resulting mechanical stress cracks the tube faster than any hammer could.

The Rule of Flow

To prevent this, patience must be engineered into the process.

- The Limit: Maximum 200 SCCM (Standard Cubic Centimeters per Minute).

- The Logic: This slow pace allows the gas to warm up as it travels toward the hot zone, neutralizing the temperature difference before it touches the critical quartz surfaces.

The 1000°C Vacuum Paradox

Vacuum operation creates a clean environment, stripping away volatile contaminants. It is the gold standard for purity.

But there is a physical interplay between heat and structural integrity that cannot be ignored.

At room temperature, a quartz tube can easily withstand the crushing force of atmospheric pressure against an internal vacuum. But as temperature rises, material properties change.

At 1000°C, the rules change.

Above this temperature, quartz begins to soften. It loses its rigidity. If you maintain a high vacuum above 1000°C, the tube is no longer strong enough to hold back the weight of the atmosphere outside. It will collapse inward.

Operational Discipline

Safety in the lab is rarely about reacting to emergencies. It is about the discipline of preventing them.

To maintain the integrity of your research and your equipment, you must operate within a "Triangle of Safety":

- Pressure: Never exceed 0.2 bar positive pressure.

- Temperature: Never use vacuum above 1000°C.

- Flow: Never exceed 200 SCCM of gas flow.

Summary of Limits

| Parameter | Safe Limit | The Risk |

|---|---|---|

| Positive Pressure | < 0.2 bar (3 psi) | Explosive fracture of the tube. |

| Vacuum Temp | < 1000°C | Tube softening and collapse. |

| Gas Flow Rate | < 200 SCCM | Thermal shock (cracking). |

Precision Requires the Right Tools

Understanding these limits is half the battle. The other half is having equipment designed to help you respect them.

When you are dealing with the physics of high heat and invisible pressure, the margin for error is non-existent. You need consumables and furnaces that are manufactured with precise uniformity, ensuring that "typical laboratory conditions" don't turn into catastrophic ones.

KINTEK understands the nuance of thermal processing. We don't just sell equipment; we provide the architectural stability your experiments rely on. Whether you are performing CVD, annealing, or sensitive atmosphere control, our systems are built to perform safely within these critical boundaries.

Do not leave your results—or your safety—to chance.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1800℃ Muffle Oven Furnace for Laboratory

Related Articles

- Why Your Brazed Joints Keep Failing: The Invisible Saboteur in Your Furnace

- The Silent Saboteur in Your Furnace: Why Your Heat Treatment Fails and How to Fix It

- The Benefits of Controlled Atmosphere Furnaces for Sintering and Annealing Processes

- Controlled Atmosphere Furnace: Comprehensive Guide to Advanced Heat Treatment

- Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits