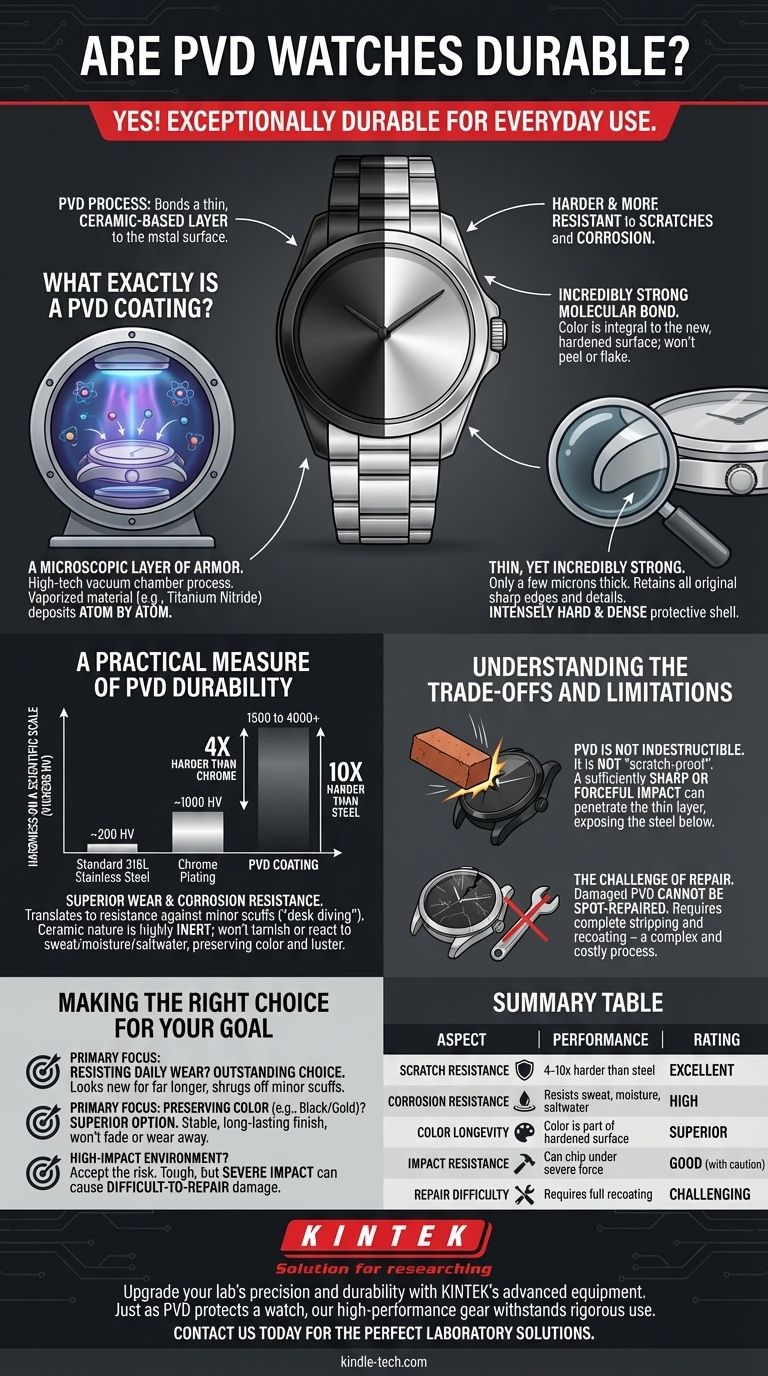

Yes, PVD-coated watches are exceptionally durable for everyday use. The Physical Vapor Deposition (PVD) process bonds a thin, ceramic-based layer to the watch's metal surface, creating a finish that is significantly harder and more resistant to scratches and corrosion than standard stainless steel or traditional plating methods. This advanced coating ensures the watch's color and finish hold up remarkably well against daily wear, including exposure to sweat and moisture.

The core takeaway is that PVD is not a simple paint or plating; it's a high-tech surface treatment that fundamentally increases the hardness and resilience of a watch. While not indestructible, it offers a dramatic upgrade in protection against the scuffs and discoloration that degrade the appearance of uncoated watches over time.

What Exactly is a PVD Coating?

A Microscopic Layer of Armor

Physical Vapor Deposition is a process conducted in a high-tech vacuum chamber. A solid, high-purity material (like titanium nitride or zirconium nitride) is vaporized and then precisely deposited, atom by atom, onto the watch's steel components.

This process creates an incredibly strong molecular bond between the coating and the base metal. The color of the watch is therefore an integral part of this new, hardened surface, not a layer that can easily peel or flake away.

Thin, Yet Incredibly Strong

PVD coatings are extremely thin, often only a few microns thick. This is a significant advantage, as it allows the watch to retain all of its original sharp edges, fine brushing, and polished details without softening the design.

Despite its thinness, this new layer is intensely hard and dense, providing a protective shell that is far more capable of withstanding daily hazards than the steel beneath it.

A Practical Measure of PVD Durability

Hardness on a Scientific Scale

The most objective measure of a material's scratch resistance is its hardness rating. PVD coatings are vastly superior to traditional watch materials in this regard.

On the Vickers hardness scale (HV), typical PVD coatings range from 1500 to over 4000 HV. For context, standard 316L stainless steel is around 200 HV, and chrome plating is around 1000 HV. This means a PVD coating can be four times harder than chrome and over ten times harder than steel.

Superior Wear and Corrosion Resistance

This exceptional hardness directly translates into superior resistance against the minor scuffs and abrasions that accumulate during daily activities, often called "desk diving" marks.

Furthermore, the ceramic nature of the coating makes it highly inert. It will not tarnish or react to sweat, moisture, or saltwater, preventing corrosion and preserving the watch's original color and luster for years.

Understanding the Trade-offs and Limitations

PVD Is Not Indestructible

While PVD provides outstanding protection against scratches, it is important to distinguish this from being "scratch-proof." The coating is still a thin layer bonded to a softer steel underneath.

A sufficiently sharp or forceful impact, like scraping the watch against a brick wall or concrete, can penetrate the PVD layer. A deep gouge can chip the coating, exposing the brighter stainless steel below.

The Challenge of Repair

This is perhaps the most significant trade-off. Unlike uncoated stainless steel, which can often be polished or re-brushed to remove scratches, a damaged PVD coating cannot be spot-repaired.

If a PVD watch is deeply scratched or chipped, restoring its original look would require the entire component to be chemically stripped and then completely recoated—a complex and often impractical process.

Making the Right Choice for Your Goal

- If your primary focus is resisting daily wear and tear: A PVD watch is an outstanding choice. It will look new for far longer than an uncoated steel watch by shrugging off the minor scuffs of everyday life.

- If your primary focus is preserving a specific color (like black or gold): PVD is the superior option. It provides a stable, long-lasting finish that won't fade or wear away from regular contact and exposure.

- If you work in a high-impact environment with frequent, heavy contact: You must accept the risk that while a PVD coating is very tough, a severe impact can cause damage that is difficult to repair.

Ultimately, a PVD coating provides a high-performance upgrade that ensures your watch maintains its intended appearance through years of consistent use.

Summary Table:

| Durability Aspect | PVD Watch Performance |

|---|---|

| Scratch Resistance | Excellent (4-10x harder than stainless steel) |

| Corrosion Resistance | High (resists sweat, moisture, saltwater) |

| Color Longevity | Superior (color is part of the hardened surface) |

| Impact Resistance | Good, but can chip under severe force |

| Repair Difficulty | Challenging (requires full recoating) |

Upgrade your lab's precision and durability with KINTEK's advanced equipment. Just as a PVD coating protects a watch from daily wear, our high-performance lab gear is built to withstand rigorous use while maintaining accuracy. Whether you need reliable consumables or robust instruments, KINTEK specializes in solutions that endure. Contact us today to find the perfect equipment for your laboratory's needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings