Yes, an induction heater is an exceptionally effective tool for melting silver. It uses an electromagnetic field to generate intense, rapid heat directly within the metal or a conductive crucible holding it. This process is prized for its speed, precision, and efficiency, making it a standard method in both jewelry making and industrial applications.

The core principle is not about applying external heat, but about inducing electrical currents inside the material itself. Because silver is an excellent electrical conductor, induction heating provides a clean, fast, and highly controllable way to bring it to its melting point of 961°C (1763°F).

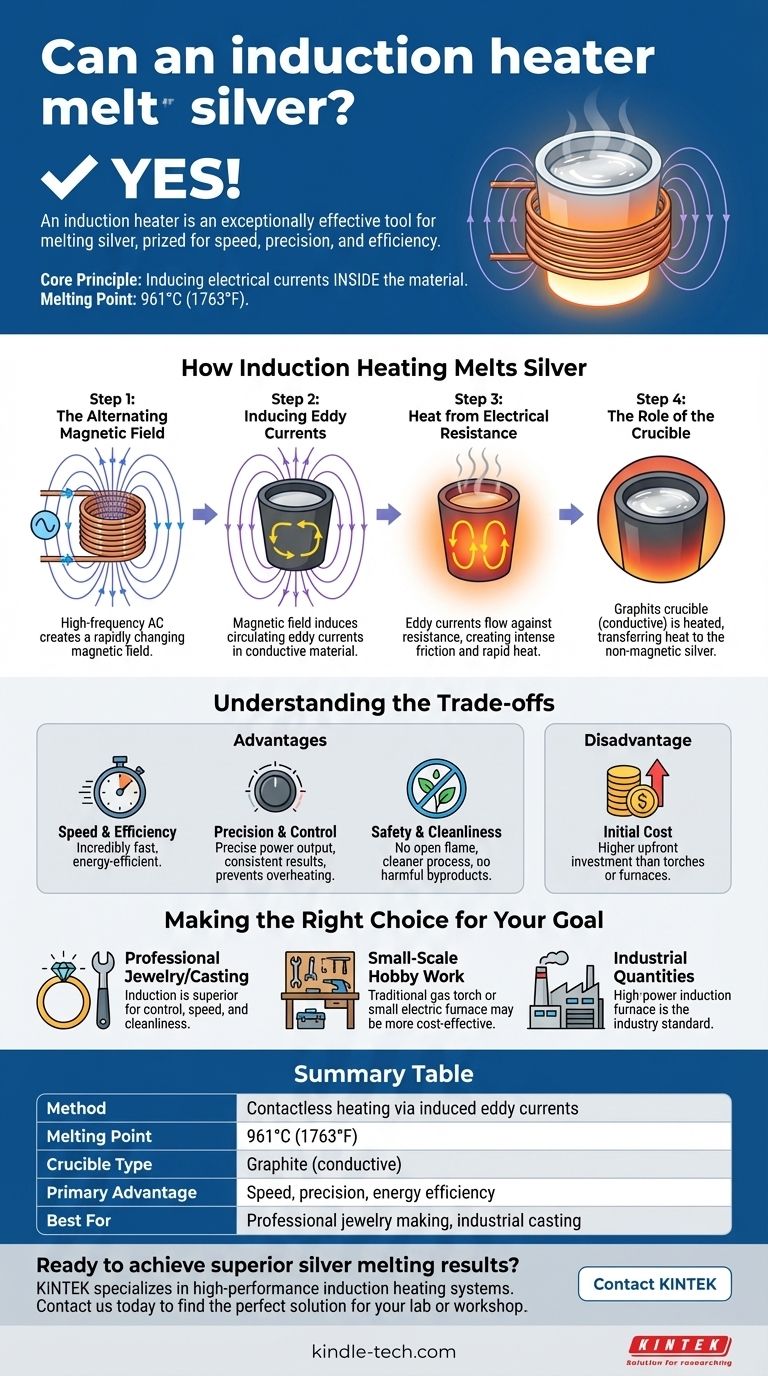

How Induction Heating Melts Silver

The process seems complex, but it relies on a few fundamental principles of physics working in sequence. It is a contactless method, meaning the heating coil itself does not get hot.

The Alternating Magnetic Field

First, a high-frequency alternating current (AC) is passed through a copper coil. This flow of electricity generates a powerful and rapidly changing magnetic field in the space within and around the coil.

Inducing Eddy Currents

When a conductive material like silver (or a graphite crucible holding the silver) is placed inside this magnetic field, the field induces circulating electrical currents within the material. These are known as eddy currents.

Heat from Electrical Resistance

These eddy currents flow against the natural electrical resistance of the silver. This opposition creates intense friction on a molecular level, which manifests as rapid and precise heat, causing the silver to quickly reach its melting point.

The Role of the Crucible

Because silver is not magnetic, the setup requires a crucible. A graphite crucible is the industry standard because it is highly conductive. The magnetic field heats the graphite, which then transfers that heat to the silver through direct contact, melting it evenly.

Understanding the Trade-offs

While highly effective, induction heating is not the only method available. Understanding its advantages and disadvantages is key to making an informed decision.

Advantage: Speed and Efficiency

Induction is incredibly fast. Heat is generated instantly within the material, wasting very little energy on heating the surrounding air. This makes it far more energy-efficient than a traditional gas furnace.

Advantage: Precision and Control

The power output of an induction heater can be controlled with extreme precision. This allows for consistent results and prevents overheating, which can damage the metal alloy.

Advantage: Safety and Cleanliness

Since there is no open flame or combustion, the process is much cleaner and produces no harmful byproducts. This is a significant benefit for indoor or workshop environments.

Disadvantage: Initial Cost

The primary drawback is the upfront investment. Professional-grade induction heating systems are significantly more expensive than a simple torch or gas-powered furnace setup.

Making the Right Choice for Your Goal

Your specific application will determine if induction heating is the most practical solution.

- If your primary focus is professional jewelry making or high-purity casting: Induction heating is the superior choice for its unparalleled control, speed, and cleanliness.

- If your primary focus is small-scale hobby work on a budget: A traditional gas torch or a small electric furnace may be a more cost-effective entry point.

- If your primary focus is melting larger, industrial quantities of silver: A high-power induction furnace is the industry standard for its efficiency and rapid cycle times.

By understanding the principles of how heat is generated, you can confidently select the right tool for your specific metalworking needs.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Method | Contactless heating via induced eddy currents |

| Melting Point | 961°C (1763°F) |

| Crucible Type | Graphite (conductive) |

| Primary Advantage | Speed, precision, and energy efficiency |

| Best For | Professional jewelry making, industrial casting |

Ready to achieve superior silver melting results?

KINTEK specializes in high-performance lab equipment, including induction heating systems designed for precise and efficient metal melting. Whether you're in jewelry making, research, or industrial production, our solutions offer the speed, control, and cleanliness you need.

Contact us today to find the perfect induction heating system for your laboratory or workshop and experience the KINTEK difference in quality and performance.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

People Also Ask

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting