Yes, Diamond-Like Carbon (DLC) can be effectively applied to aluminum and its various alloys. This combination is actively used and researched for high-performance components where the lightweight nature of aluminum must be paired with superior surface hardness and low friction. Applications range from automotive pistons and engine bores to precision machinery components.

The challenge isn't whether DLC can be applied to aluminum, but how it's applied. Successfully bonding the ultra-hard DLC film to the soft aluminum substrate requires specialized techniques, most notably the use of an intermediate bonding layer to ensure durability.

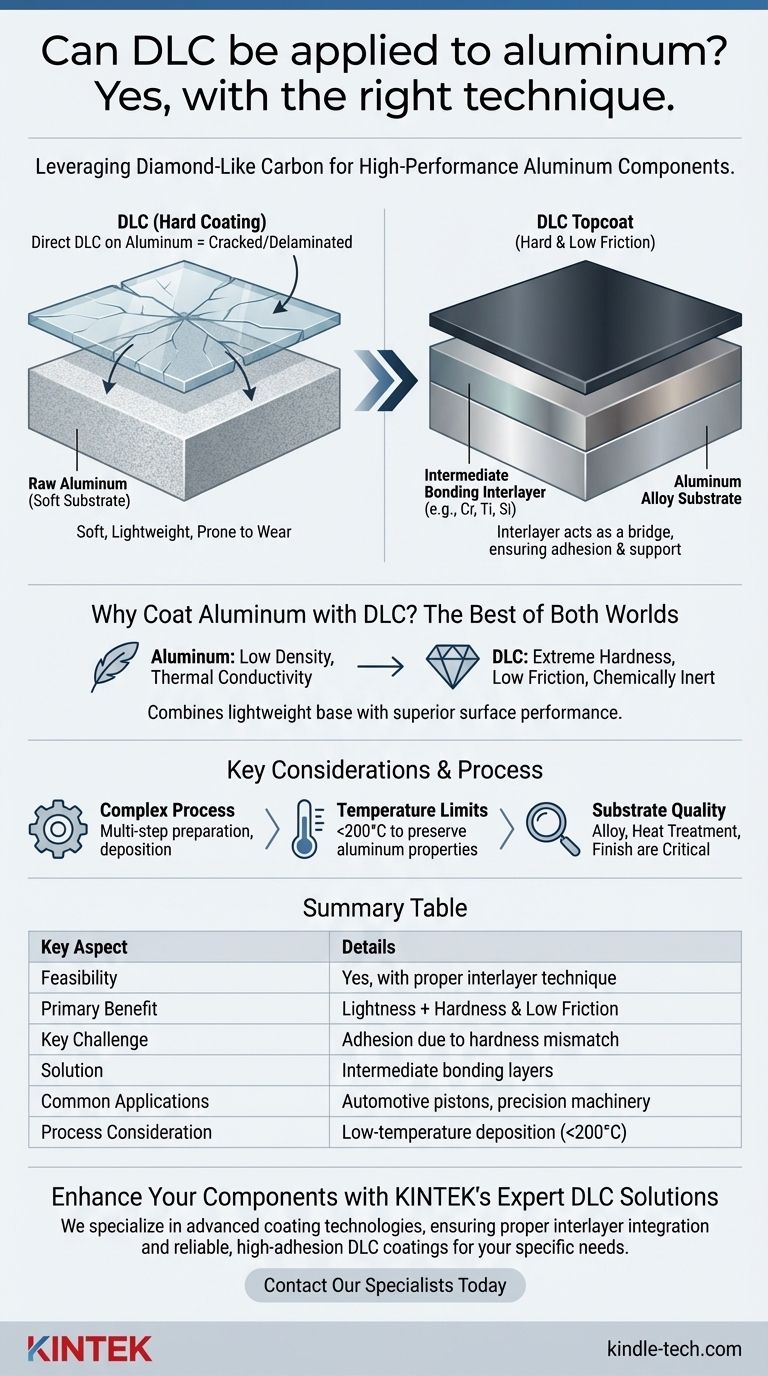

Why Coat Aluminum with DLC?

The primary goal is to combine the best properties of two very different materials. Engineers turn to this solution to overcome the inherent limitations of aluminum in demanding environments.

The Problem with Raw Aluminum

While valued for its low density and excellent thermal conductivity, aluminum is a relatively soft metal. This makes it prone to scratching, abrasive wear, and galling (a form of wear caused by adhesion between sliding surfaces).

The Solution DLC Provides

DLC coatings are exceptionally hard, chemically inert, and have an extremely low coefficient of friction. Applying a thin layer of DLC transforms the surface of an aluminum part, giving it a performance profile it could never achieve on its own.

This creates a component that is simultaneously lightweight and highly resistant to wear and friction, making it ideal for moving parts in automotive or textile machinery.

The Critical Challenge: Adhesion

Directly applying a hard DLC film onto a soft aluminum substrate is destined for failure. The vast difference in mechanical properties creates a weak interface that will quickly crack and delaminate under stress or temperature changes.

The Soft Substrate Problem

A very hard coating on a soft base is like a thin sheet of glass on a foam pillow. Any significant point load will deform the soft aluminum underneath, causing the inflexible DLC layer to crack because it lacks support.

The Interlayer Solution

To solve this, coating specialists use an interlayer. This is a thin metallic or ceramic layer deposited onto the aluminum before the DLC is applied. Common interlayers include chromium (Cr), titanium (Ti), or silicon (Si).

This interlayer acts as a bridge, creating a gradual transition in hardness from the soft aluminum to the hard DLC. It dramatically improves adhesion and provides the necessary structural support for the final DLC film.

Understanding the Trade-offs

While powerful, this process involves key considerations that impact cost and complexity.

Increased Process Complexity

Applying DLC to aluminum is not a single-step process. It requires careful surface preparation, deposition of the adhesion-promoting interlayer, and finally, the deposition of the DLC topcoat, often in a multi-chamber vacuum system.

Temperature Limitations

Most high-quality DLC films are applied using Plasma-Assisted Chemical Vapor Deposition (PA-CVD). The process temperature must be kept low enough (typically below 200°C) to avoid altering the temper or metallurgical properties of the aluminum alloy substrate.

Substrate Quality is Paramount

The final performance of the coated part depends heavily on the quality of the aluminum itself. The specific alloy, its heat treatment, and the initial surface finish are all critical factors that must be controlled for a successful outcome.

Making the Right Choice for Your Application

Successfully leveraging DLC on aluminum requires a clear understanding of your engineering goal.

- If your primary focus is maximum wear and load resistance: You must specify a coating process that includes a well-chosen, robust interlayer to support the DLC film.

- If your primary focus is reducing friction in a low-load scenario: A simpler DLC formulation may be possible, but ensuring strong adhesion via an interlayer remains the most critical factor for reliability.

- If you are developing a new application: Partnering with a coating specialist is essential to match the specific aluminum alloy, interlayer material, and DLC type to your component's operating conditions.

Ultimately, success with DLC on aluminum is achieved by properly managing the critical interface between the coating and the substrate.

Summary Table:

| Key Aspect | Details |

|---|---|

| Feasibility | Yes, with proper interlayer technique |

| Primary Benefit | Combines aluminum's lightness with DLC's hardness and low friction |

| Key Challenge | Adhesion due to hardness mismatch between DLC and soft aluminum substrate |

| Solution | Use of intermediate bonding layers (e.g., chromium, titanium) |

| Common Applications | Automotive pistons, engine bores, precision machinery components |

| Process Consideration | Low-temperature deposition (<200°C) to preserve aluminum properties |

Enhance Your Aluminum Components with Expert DLC Coating Solutions

Are you designing high-performance parts that need the lightweight benefits of aluminum combined with extreme surface durability? KINTEK specializes in advanced coating technologies, including Diamond-Like Carbon (DLC) applications for aluminum substrates. Our expertise ensures proper interlayer integration and low-temperature processes to deliver reliable, high-adhesion coatings tailored for your laboratory or industrial needs.

We provide lab equipment and consumables to support your R&D and production, helping you achieve superior wear resistance and reduced friction for components in automotive, aerospace, and precision machinery.

Ready to optimize your aluminum parts? Contact our coating specialists today to discuss your specific application requirements!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- Is diamond coating worth it? Maximize Component Life and Performance