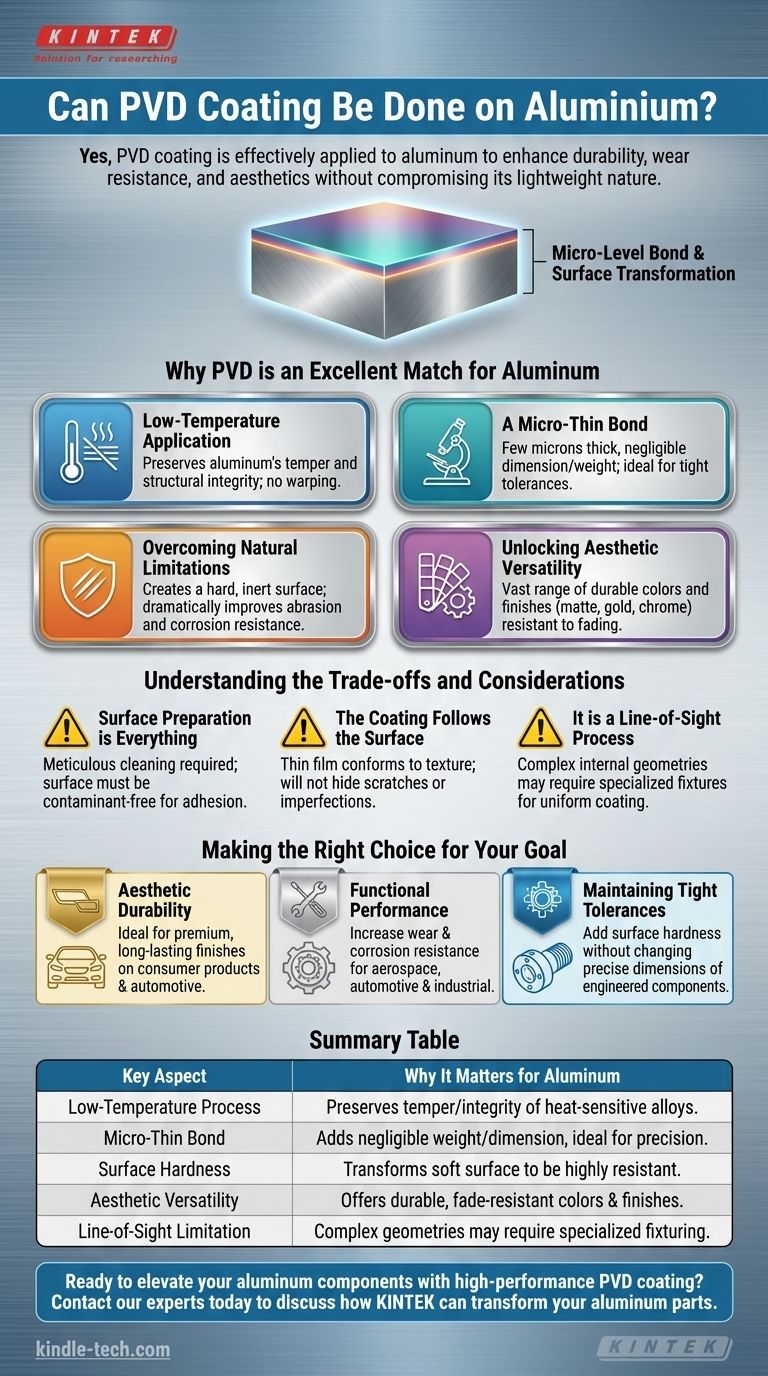

Yes, PVD coating is frequently and effectively applied to aluminum. This process is used to enhance the metal's inherent properties, adding superior durability, wear resistance, and a wide range of aesthetic finishes without compromising its lightweight nature.

The core insight is that PVD (Physical Vapor Deposition) is not just a coating on aluminum, but a micro-level bond with its surface. This transforms the aluminum part, giving it the surface characteristics of a much harder or more corrosion-resistant material while preserving its original dimensions and weight.

Why PVD is an Excellent Match for Aluminum

While aluminum is valued for being lightweight, it is also relatively soft and susceptible to scratches and corrosion. PVD coating directly addresses these weaknesses.

The Advantage of Low-Temperature Application

Many coating processes require high heat, which can alter the temper and structural integrity of heat-sensitive aluminum alloys. PVD can be applied at relatively low temperatures, ensuring the underlying metal's properties remain unchanged.

A Micro-Level Bond, Not a Thick Layer

PVD is not like paint or plating. It is a thin-film process that bonds with the aluminum at a microscopic level, typically only a few microns thick.

This means it creates a new surface condition rather than adding a substantial layer. This is critical for engineered components with tight tolerances, as the process adds negligible dimension or weight.

Overcoming Aluminum's Natural Limitations

PVD deposition creates a ceramic or metallic surface layer that is exceptionally hard and inert. This new surface acts as a protective barrier, dramatically improving the aluminum's resistance to abrasion, scratching, and chemical attack.

Unlocking Aesthetic Versatility

The PVD process allows for a vast range of colors and finishes—from matte black to gold, bronze, and chrome-like sheens. These finishes are far more durable and resistant to fading or chipping than traditional paint or anodizing.

Understanding the Trade-offs and Considerations

While powerful, the PVD process has specific requirements that are crucial for success, especially with a reactive metal like aluminum.

Surface Preparation is Everything

PVD requires a perfectly clean, smooth, and contaminant-free surface for proper adhesion. The aluminum part must be meticulously cleaned to remove any oils, oxides, or imperfections before it enters the vacuum chamber.

The Coating Follows the Surface

The PVD film is extremely thin and will conform to the exact texture of the underlying material. It will not hide or fill in scratches, dents, or polishing marks. Your part's final finish quality is determined before the coating is applied.

It is a Line-of-Sight Process

In a PVD chamber, the coating material travels in a straight line to the part. This means that complex internal geometries or deep, narrow channels can be difficult to coat uniformly without specialized fixtures and part rotation during the process.

Making the Right Choice for Your Goal

PVD is an investment in performance and longevity. Consider your primary objective when deciding if it is the right solution for your aluminum component.

- If your primary focus is aesthetic durability: PVD is an ideal choice for achieving a premium, long-lasting finish on consumer products, automotive trim, or architectural elements.

- If your primary focus is functional performance: Use PVD to dramatically increase the wear and corrosion resistance of functional aluminum parts in aerospace, automotive, or industrial applications.

- If your primary focus is maintaining tight tolerances: Choose PVD when you need to add surface hardness without changing the precise dimensions of a machined aluminum component.

By bonding a high-performance layer to its surface, PVD coating elevates aluminum from a lightweight metal to a true high-performance material.

Summary Table:

| Key Aspect | Why It Matters for Aluminum |

|---|---|

| Low-Temperature Process | Preserves the temper and structural integrity of heat-sensitive aluminum alloys. |

| Micro-Thin Bond | Adds negligible weight or dimension, ideal for precision components. |

| Surface Hardness | Transforms the soft aluminum surface to be highly resistant to scratches and abrasion. |

| Aesthetic Versatility | Offers a wide range of durable, fade-resistant colors and finishes. |

| Line-of-Sight Limitation | Complex geometries may require specialized fixturing for uniform coating. |

Ready to elevate your aluminum components with high-performance PVD coating? KINTEK specializes in precision lab equipment and consumables, providing solutions that enhance durability and aesthetics for your laboratory and industrial needs. Contact our experts today to discuss how our PVD coating services can transform your aluminum parts into high-performance assets.

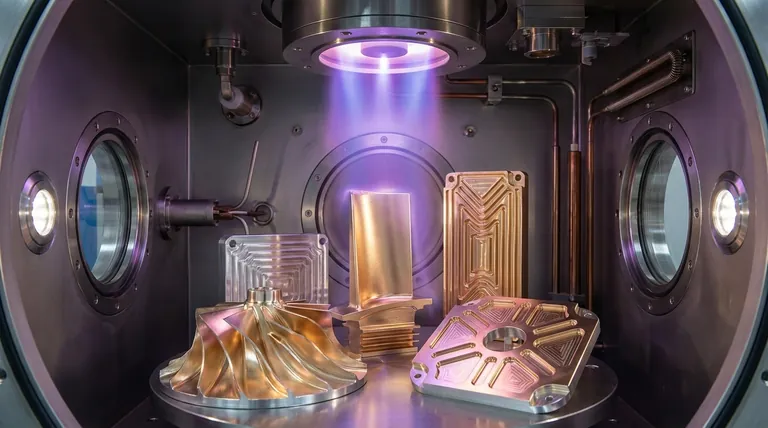

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Tungsten Evaporation Boat for Thin Film Deposition

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition