Yes, you can test diamonds with a machine, but the type of machine you use is critical. Basic, handheld testers are designed to distinguish diamonds from common fakes, while far more complex and expensive equipment is needed to determine if a diamond is natural or lab-grown.

The core issue is not simply testing if a stone is a diamond, but understanding its origin. While simple tools can confirm a stone's identity, only specialized laboratory machines can reliably differentiate a natural diamond from a synthetic one.

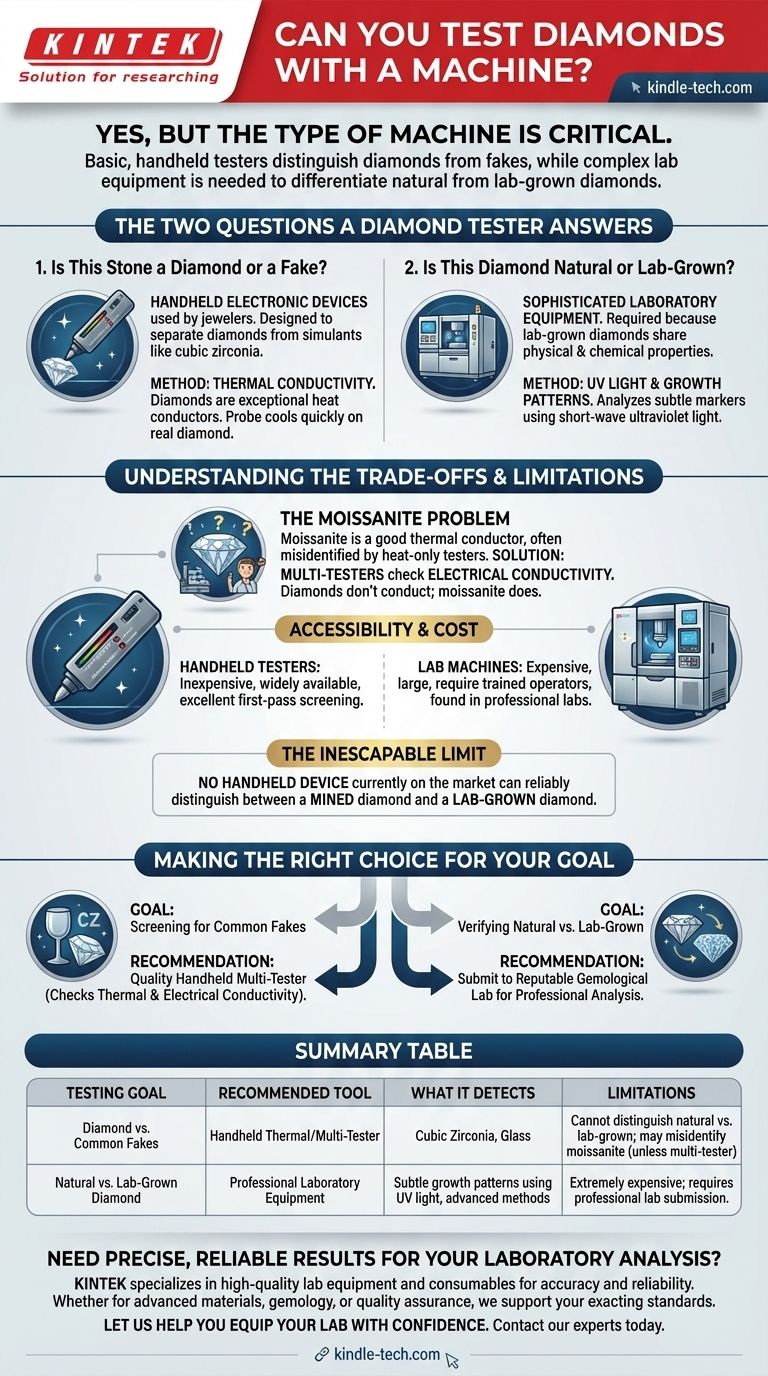

The Two Questions a Diamond Tester Answers

When testing a diamond, you are typically asking one of two fundamental questions. The technology required to answer each is vastly different.

1. Is This Stone a Diamond or a Fake?

The most common "diamond testers" are handheld electronic devices used by jewelers. These tools are designed to separate diamonds from simulants like cubic zirconia.

They primarily work by measuring thermal conductivity. Diamonds are exceptional conductors of heat, so the tester's probe quickly cools when it touches a real diamond, triggering a positive result.

2. Is This Diamond Natural or Lab-Grown?

This is a much harder question to answer because lab-grown diamonds have the same physical and chemical properties as natural ones. A basic thermal tester cannot tell them apart.

Answering this requires sophisticated laboratory equipment. Companies like De Beers and ALROSA have developed machines that use methods like short-wave ultraviolet light to analyze a diamond's growth patterns and identify the subtle markers that distinguish a natural stone from a synthetic one.

Understanding the Trade-offs and Limitations

No single machine provides a simple, catch-all solution. Understanding the limits of each technology is key to getting an accurate assessment.

The Moissanite Problem

Moissanite, a man-made diamond simulant, is also an excellent thermal conductor. A basic diamond tester that only measures heat will often incorrectly identify moissanite as a diamond.

To solve this, jewelers use "multi-testers" that check for electrical conductivity in addition to heat. Diamonds do not conduct electricity, but moissanite does, allowing these more advanced handheld devices to tell them apart.

Accessibility and Cost

Handheld thermal and multi-testers are relatively inexpensive and widely available. They are excellent first-pass screening tools for identifying obvious fakes.

The specialized machines that can detect synthetic diamonds are extremely expensive, large, and require trained operators. They are found almost exclusively in professional gemological laboratories.

The Inescapable Limit of Basic Testers

It is crucial to understand that no handheld device currently on the market can reliably distinguish between a mined diamond and a lab-grown diamond. Their properties are too similar for such a simple test.

Making the Right Choice for Your Goal

The correct approach depends entirely on what you need to verify.

- If your primary focus is screening for common fakes (like glass or cubic zirconia): A quality handheld multi-tester that checks for both thermal and electrical conductivity is a practical tool.

- If your primary focus is verifying if a diamond is natural or lab-grown: You must submit the stone to a reputable gemological lab for professional analysis.

Ultimately, understanding the capabilities of different testing technologies allows you to seek the right verification for your specific needs.

Summary Table:

| Testing Goal | Recommended Tool | What It Detects | Limitations |

|---|---|---|---|

| Diamond vs. Common Fakes | Handheld Thermal/Multi-Tester | Cubic Zirconia, Glass | Cannot distinguish natural from lab-grown diamonds; may misidentify moissanite (unless using a multi-tester). |

| Natural vs. Lab-Grown Diamond | Professional Laboratory Equipment | Subtle growth patterns using UV light and other advanced methods | Extremely expensive and inaccessible for most individuals; requires professional lab submission. |

Need precise, reliable results for your laboratory analysis?

Accurate material identification is the foundation of trustworthy research and quality control. KINTEK specializes in providing high-quality lab equipment and consumables to support your exacting standards. Whether you're working with advanced materials, gemology, or industrial quality assurance, our solutions are designed for accuracy and reliability.

Let us help you equip your lab with confidence. Contact our experts today to discuss your specific application needs.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- What is the future value of lab grown diamond? Understanding Its Depreciating Financial Worth

- What are the common sources of contamination during CVD diamond growth? Improve Purity and Quality Control

- Are CVD diamonds better than HPHT? The Real Truth About Lab-Grown Diamond Quality

- What is the fluorescence of a CVD diamond? A Guide to Its Unique Glow and Purpose

- What is the main difference between CVD and natural diamond? Origin, Purity, and Value Explained