In short, yes, PVD-coated watches can and do scratch. While the coating itself is quite hard and resistant to minor scuffs, a significant impact or scrape against a hard, sharp surface will compromise the coating. The visibility and permanence of these scratches are the true issues to consider, as the bright metal beneath the dark coating is exposed, creating a high-contrast mark that cannot be polished away.

The core issue with PVD isn't just about whether it scratches, but what happens when it does. Unlike a scratch on solid stainless steel, a scratch on a PVD watch reveals the underlying metal, creating a permanent and highly visible blemish that cannot be easily repaired.

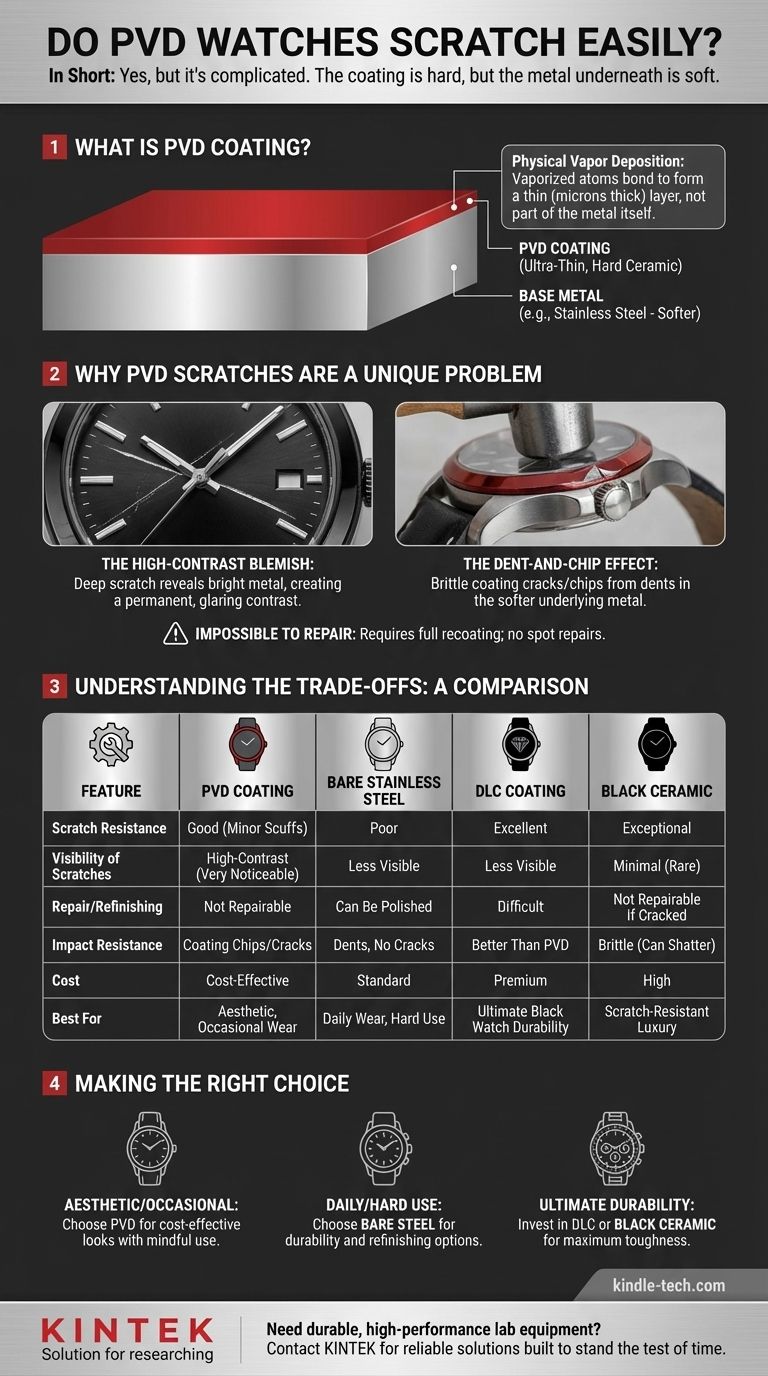

What Exactly is PVD Coating?

To understand its durability, you must first understand what PVD is. It isn't the metal itself, but an advanced, ultra-thin film applied on top of it.

The Science of Physical Vapor Deposition

Physical Vapor Deposition (PVD) is a process conducted in a high-tech vacuum chamber. A solid coating material, often a durable ceramic like titanium nitride, is vaporized into a plasma of atoms. These atoms are then bonded molecule by molecule onto the watch's case and bracelet, forming a thin, hard, and uniform layer.

It's a Coating, Not the Metal Itself

This is the most critical concept to grasp. The PVD layer is typically only a few microns thick—thinner than a human hair. While it is chemically bonded to the base metal (usually stainless steel), it remains a distinct surface layer. It is not a treatment that changes the properties of the steel itself.

The Duality of Hardness

The PVD coating material is often significantly harder than the stainless steel beneath it. This provides excellent resistance to light, everyday scuffs and swirls that would easily mark up a non-coated, polished steel watch.

Why PVD Scratches Are a Unique Problem

The hardness of the coating can be misleading. The vulnerability of a PVD watch comes from the interaction between the thin coating and the softer metal underneath.

The High-Contrast Blemish

When a PVD watch gets a deep scratch, the coating is removed, exposing the bright, silvery stainless steel underneath. This creates a glaring contrast against the dark PVD surface, making the scratch far more noticeable than a similar scratch on a uniform steel watch.

The Dent-and-Chip Effect

A sharp knock on a doorframe won't just scratch the surface; it can dent the softer steel below the coating. Because the PVD layer is hard but brittle, this underlying dent can cause the coating to crack, chip, or flake off around the point of impact, revealing the steel.

The Impossibility of Repair

A scratch on a standard stainless steel watch can often be polished or brushed out, restoring the finish. A scratch on a PVD watch is permanent. There is no way to "spot repair" the missing coating. The only true fix is to have the entire component professionally stripped and re-coated, a process that is rarely practical or cost-effective.

Understanding the Trade-offs: PVD vs. Other Options

PVD is one of several choices for achieving a black watch, each with distinct advantages and disadvantages.

PVD vs. Bare Stainless Steel

Stainless steel scratches more easily than a PVD coating, but these scratches are less visible and can often be repaired. PVD resists minor scuffs better, but major scratches are permanent and highly visible. Steel "ages" while PVD "damages."

PVD vs. DLC (Diamond-Like Carbon)

DLC is another coating applied via a similar process, but it is a demonstrably superior material. As its name implies, it has properties similar to diamond, making it significantly harder, more durable, and more scratch-resistant than standard PVD. It is the premium choice for a coated watch and comes with a higher price tag.

PVD vs. Black Ceramic

A solid black ceramic case is not a coating at all; the material is black through and through. Ceramic is exceptionally scratch-resistant—far more so than PVD, DLC, or even steel. However, it is also more brittle and can crack or shatter under a severe impact, whereas metal would only dent.

Making the Right Choice for Your Watch

Your decision should be based entirely on how you plan to wear the watch and your tolerance for signs of wear.

- If your primary focus is a striking aesthetic for careful or occasional wear: PVD is a cost-effective and excellent choice that will maintain its look with mindful use.

- If your primary focus is a durable daily watch that will see hard use: Avoid PVD and choose bare stainless steel, which can handle abuse and be refinished if needed.

- If your primary focus is the ultimate durability of a black watch: Invest more in a watch with a superior DLC coating or one made from solid black ceramic.

By understanding these material properties, you can choose a watch that will align with your lifestyle and expectations for years to come.

Summary Table:

| Feature | PVD Coating | Bare Stainless Steel | DLC Coating | Black Ceramic |

|---|---|---|---|---|

| Scratch Resistance | Good for minor scuffs | Poor | Excellent | Exceptional |

| Visibility of Scratches | High-contrast, very noticeable | Less visible | Less visible than PVD | Minimal (scratches rare) |

| Repair/Refinishing | Not repairable; requires full recoating | Can be polished/brushed | Difficult to repair | Not repairable if cracked |

| Impact Resistance | Coating can chip/crack from dents | Dents but doesn't crack/chip | Better than PVD | Brittle; can shatter |

| Cost | Cost-effective | Standard | Premium | High |

| Best For | Aesthetic, occasional wear | Daily wear, hard use | Ultimate black watch durability | Scratch-resistant, luxury wear |

Need durable, high-performance lab equipment? At KINTEK, we specialize in precision lab equipment and consumables, built to withstand rigorous daily use. Whether you're outfitting a research lab or need reliable tools for industrial applications, our products are designed for longevity and accuracy. Contact our experts today to find the perfect solution for your laboratory needs and ensure your equipment stands the test of time.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition