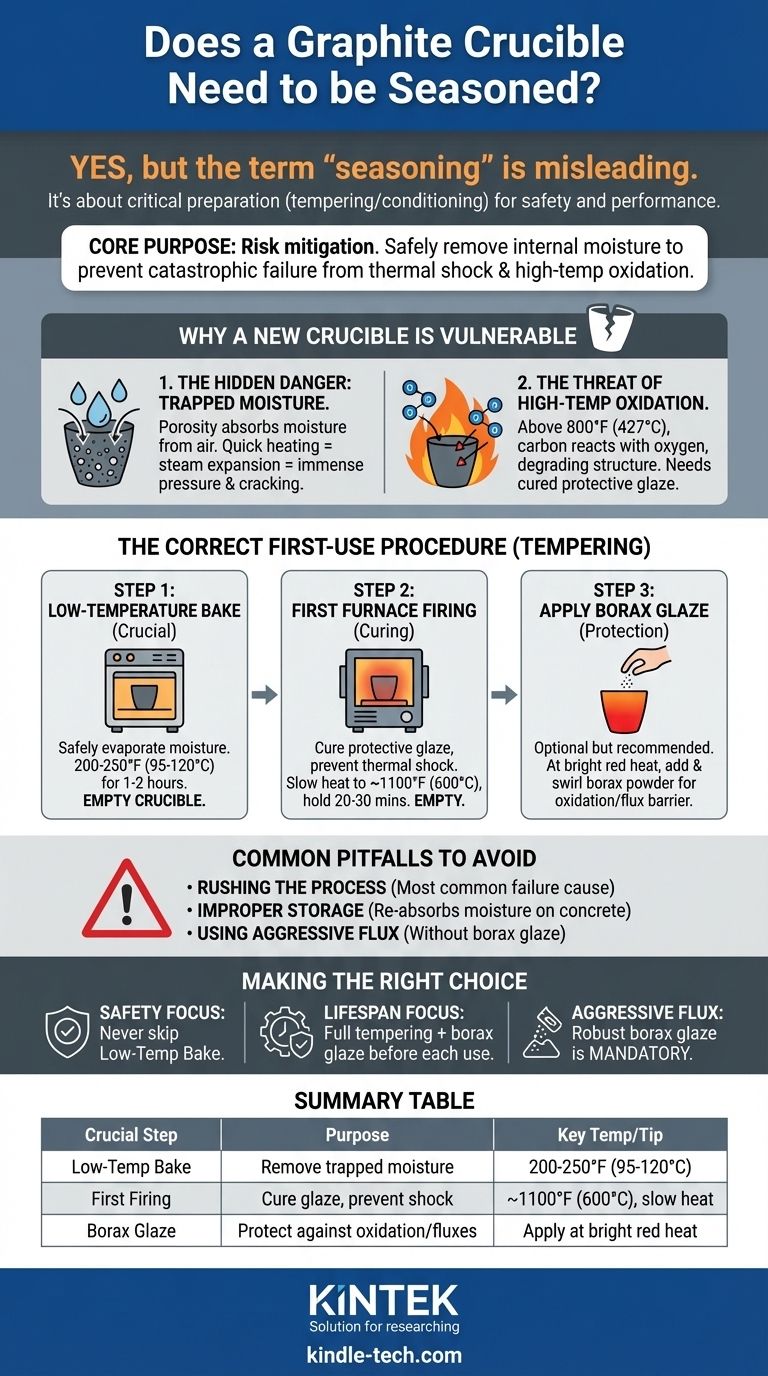

Yes, but the term "seasoning" can be misleading. A new graphite crucible requires a critical, one-time preparation process, often called tempering or conditioning. This initial, slow heating cycle is not about creating a non-stick surface like in cookware; it's an essential safety procedure to drive out trapped moisture and activate its protective glaze, preventing it from cracking or exploding during its first real use.

The core purpose of preparing a new crucible is not seasoning, but risk mitigation. You are performing a slow, controlled initial firing to safely remove internal moisture and prevent catastrophic failure from thermal shock and high-temperature oxidation.

Why a New Crucible is Vulnerable

A new crucible, while appearing robust, is in its most fragile state before its first proper heating. Two primary factors contribute to this vulnerability.

The Hidden Danger: Trapped Moisture

Graphite and the clay or ceramic binders used in crucibles are porous materials. During shipping and storage, they readily absorb microscopic water molecules from the ambient air.

When heated too quickly, this trapped moisture turns to steam and expands violently. This rapid expansion inside the crucible's structure creates immense internal pressure, leading to cracks or even a complete, explosive failure inside your furnace.

The Threat of High-Temperature Oxidation

The "graphite" in your crucible is carbon. At high temperatures, typically above 800°F (427°C), carbon reacts with oxygen in the air and essentially burns away.

This process, called oxidation, degrades the crucible's structure, making it weaker and reducing its lifespan. Most modern crucibles are coated with a protective glaze that acts as an oxygen barrier, but this glaze must be properly cured during the first firing to be effective.

The Correct First-Use Procedure (Tempering)

This process should never be rushed. The goal is a slow and steady increase in temperature to give moisture time to escape and the crucible time to adapt.

Step 1: The Low-Temperature Bake

This is the most critical step for moisture removal. Place the empty crucible in a kitchen oven at around 200-250°F (95-120°C) for at least one to two hours. This gentle, dry heat is the safest way to evaporate the majority of the trapped water.

If you don't have an oven, you can achieve this by placing the crucible at the top opening of your furnace while it's running at a very low temperature, allowing the waste heat to warm it slowly.

Step 2: The First Furnace Firing (Empty)

After the low-temp bake, place the empty crucible inside your furnace. Heat it slowly, aiming for a dull red glow (around 1100°F / 600°C). Hold it at this temperature for about 20-30 minutes.

This stage continues to drive off any remaining moisture and begins to sinter, or "set," the manufacturer's protective glaze. Afterward, you can slowly increase the temperature to your intended working heat.

Step 3: Applying a Borax Glaze

Once the crucible is at a bright red heat, you can add a protective borax glaze. This is especially important if your crucible is un-glazed or if you plan to use aggressive chemical fluxes.

Carefully add a spoonful of anhydrous borax powder. It will melt and can be swirled around to coat the entire inner surface, creating a glass-like barrier that protects against oxidation and chemical attack from fluxes.

Common Pitfalls to Avoid

Proper procedure is straightforward, but mistakes can be costly and dangerous. Being aware of common errors is key to ensuring your equipment's longevity.

Rushing the Process

This is the single most common cause of crucible failure. Subjecting a new, unprepared crucible directly to high heat is a recipe for thermal shock and cracking. Always perform the slow initial heat-up.

Improper Storage

A properly tempered crucible can re-absorb moisture if stored incorrectly. Never store your crucible directly on a concrete floor, which can be a source of moisture. Keep it in a warm, dry location, preferably on a wooden shelf.

Using Aggressive Flux

Flux is used to remove impurities from molten metal, but some types can be highly corrosive to the crucible itself. A properly applied borax glaze is essential to create a protective barrier between the flux and the crucible wall.

Making the Right Choice for Your Goal

Your approach to crucible care should align with your primary objective, whether it's basic safety or maximizing the life of your investment.

- If your primary focus is safety and avoiding failure: The slow, initial low-temperature bake to remove moisture is the one step you must never skip.

- If your primary focus is maximizing crucible lifespan: Perform the full tempering process and re-apply a thin borax glaze before each use to protect against oxidation.

- If you are working with aggressive chemical fluxes: A robust, fully coated borax glaze is absolutely mandatory to prevent the flux from eating through the crucible walls.

Treating your crucible with care is not a chore; it is a fundamental practice that ensures safety, reliability, and better results in your work.

Summary Table:

| Crucial Step | Purpose | Key Temperature/Tip |

|---|---|---|

| Low-Temp Bake | Safely remove trapped moisture | 200-250°F (95-120°C) for 1-2 hours |

| First Furnace Firing | Cure protective glaze, prevent thermal shock | Heat slowly to ~1100°F (600°C) |

| Borax Glaze Application | Protect against oxidation & aggressive fluxes | Apply at bright red heat |

Ensure your lab's safety and crucible performance with KINTEK.

Properly preparing your graphite crucible is essential for preventing dangerous failures and achieving consistent results. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable crucibles and expert guidance your laboratory needs.

Let us help you protect your investment and your team. Contact our experts today to discuss your specific application and find the perfect crucible solution.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Evaporation

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

People Also Ask

- Can you use stainless steel as a crucible? A Guide to Safe & Effective Material Choices

- What is the classification of a crucible furnace? A Guide to Fuel-Fired, Electric & Induction Types

- What are the safety precautions for a crucible? Prevent Thermal Shock and Ensure Lab Safety

- What is the role of the stainless steel crucible in magnesium melting? Master AM60 Vacuum Process Parameters

- What role do High-Purity Alumina Crucibles play in molten salt electrolytic deoxygenation? Ensure Peak Purity at 1173 K

- What crucible is best for melting copper? Choose the Right Crucible for Clean, Efficient Melts

- Why do my crucibles keep breaking? Prevent Thermal Shock and Extend Crucible Life

- Why are alumina crucibles preferred for DSC analysis of SiCp/2009Al? Ensure High-Temperature Chemical Inertness