Yes, induction heating works effectively on titanium. However, the process is fundamentally different from heating more common metals like steel due to titanium's unique electrical and magnetic properties, requiring specific adjustments to equipment and methodology for optimal results.

While titanium's high electrical resistance is an advantage for generating heat, its non-magnetic nature presents the primary challenge. Success requires a well-engineered process, typically involving higher frequencies and precise coil design to overcome this and achieve efficient heating.

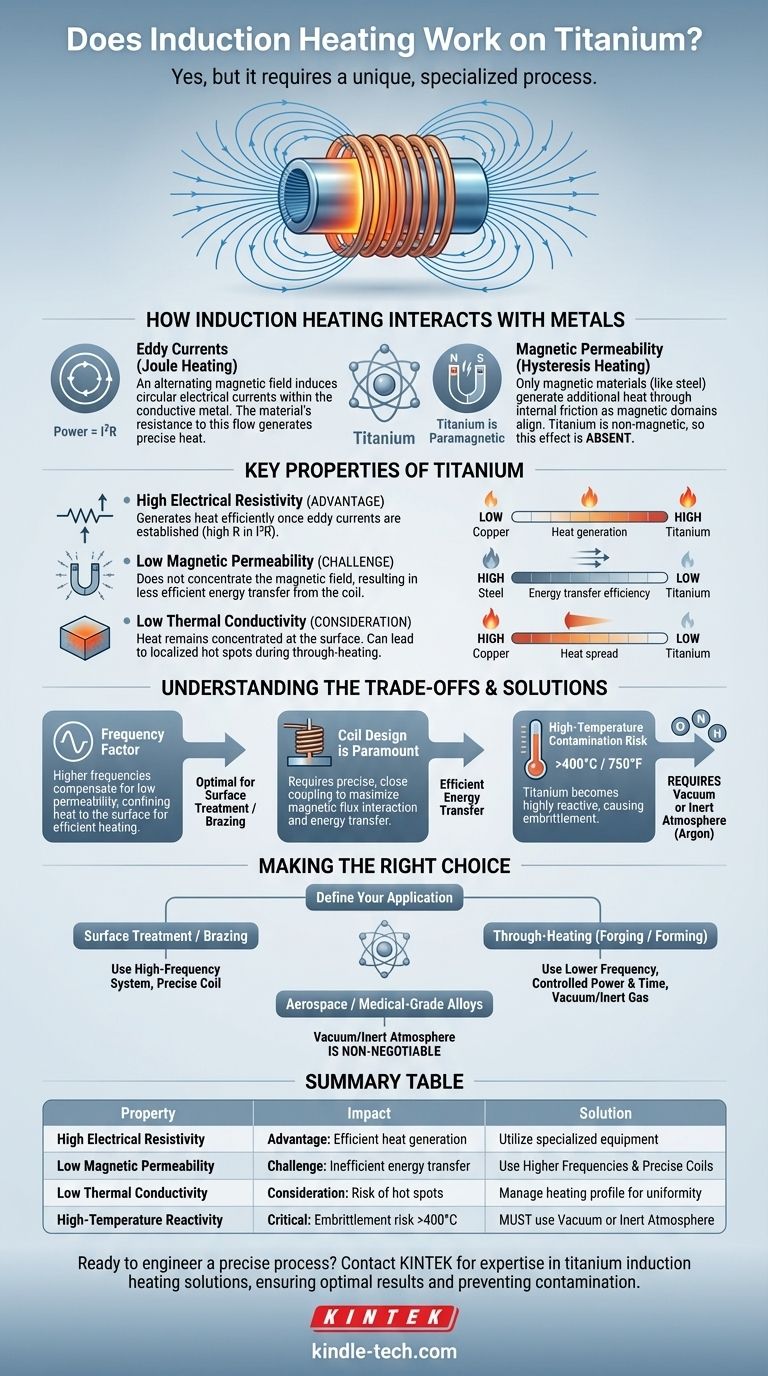

How Induction Heating Interacts with Metals

To understand why titanium behaves differently, it's essential to grasp the two core principles of induction heating.

The Role of Eddy Currents

An induction heater's coil generates a powerful, alternating magnetic field. When a conductive material like titanium is placed inside this field, the field induces circular electrical currents within the metal, known as eddy currents.

The material's own electrical resistance fights against the flow of these currents. This opposition creates immense friction on an atomic level, which manifests as rapid and precise heat, a phenomenon known as Joule heating.

The Impact of Magnetic Permeability

The second heating effect, hysteresis heating, only applies to magnetic materials like iron and steel. These materials resist the rapid switching of the magnetic field, generating additional internal friction and heat.

Titanium is paramagnetic, meaning it is not magnetic. Therefore, it does not benefit from hysteresis heating. All of the heat generated in titanium comes purely from eddy currents, making the efficiency of inducing those currents the single most important factor.

Key Properties of Titanium for Induction Heating

Titanium's unique characteristics present both advantages and challenges that must be managed.

Advantage: High Electrical Resistivity

Compared to copper or aluminum, titanium has a relatively high electrical resistivity. This is a significant benefit for induction heating.

According to the Joule heating formula (Power = I²R), a higher resistance (R) results in more heat being generated for a given amount of electrical current (I). This allows titanium to heat up very quickly once sufficient eddy currents are established.

Challenge: Low Magnetic Permeability

The primary challenge is titanium's low magnetic permeability. Ferromagnetic materials like steel actively concentrate the magnetic field lines, which allows for highly efficient energy transfer from the coil to the part.

Because titanium is non-magnetic, it does not concentrate the field. This results in weaker eddy currents and less efficient energy transfer, requiring more power or a more refined setup to achieve the same heating rate as steel.

Consideration: Low Thermal Conductivity

Titanium also has low thermal conductivity. This means heat does not spread through the material quickly.

The heat generated by induction remains concentrated near the surface where the eddy currents are strongest. This is excellent for applications like surface hardening, but it can lead to localized overheating or "hot spots" if the goal is to heat a large billet uniformly.

Understanding the Trade-offs and Solutions

Successfully heating titanium with induction involves compensating for its non-magnetic nature and managing its thermal properties.

The Frequency Factor

The frequency of the induction power supply is a critical variable. Higher frequencies tend to confine the heating effect to a shallower depth near the surface.

For titanium, higher frequencies are often used to compensate for the low magnetic permeability. This helps to generate strong enough eddy currents at the surface for efficient heating, making it ideal for processes like brazing, soldering, and surface treatments.

Coil Design is Paramount

Because energy transfer is less efficient than with steel, the design and placement of the induction coil are critical.

The coil must be coupled as closely as possible to the titanium part without touching it. This ensures that the maximum amount of magnetic flux interacts with the workpiece, maximizing the induced eddy currents.

The Risk of High-Temperature Contamination

At elevated temperatures (typically above 400°C or 750°F), titanium becomes highly reactive with oxygen, nitrogen, and hydrogen. This can cause embrittlement and compromise the material's integrity.

For this reason, high-temperature induction processes for titanium, such as forging or heat treating, must be performed in a vacuum or an inert gas atmosphere (like argon) to protect the material from contamination.

Making the Right Choice for Your Application

Tailoring the induction process to the material and the goal is the key to success.

- If your primary focus is surface treatment or brazing: A high-frequency induction system is ideal to concentrate energy at the surface and overcome the low permeability.

- If your primary focus is through-heating for forging or forming: A lower frequency with carefully controlled power and longer heating times is necessary to allow the heat to soak through the material without causing surface overheating.

- If you are working with aerospace or medical-grade alloys: Performing the heating process in a vacuum or inert atmosphere is non-negotiable to prevent contamination and preserve the material's critical properties.

By understanding these principles, you can engineer an effective and precise induction heating process for even the most demanding titanium applications.

Summary Table:

| Key Property of Titanium | Impact on Induction Heating |

|---|---|

| High Electrical Resistivity | Advantage: Generates heat efficiently once eddy currents are established. |

| Low Magnetic Permeability | Challenge: Requires higher frequencies and precise coil design for efficient energy transfer. |

| Low Thermal Conductivity | Consideration: Heat is concentrated at the surface; risk of hot spots during through-heating. |

| High-Temperature Reactivity | Critical: Requires a vacuum or inert atmosphere (e.g., argon) above 400°C (750°F) to prevent embrittlement. |

Ready to engineer a precise and efficient induction heating process for your titanium components?

At KINTEK, we specialize in providing advanced lab equipment and consumables for demanding applications. Whether you are brazing, heat treating, or forging aerospace or medical-grade titanium alloys, our expertise ensures you achieve optimal results while preventing contamination.

Contact our experts today to discuss your specific titanium heating challenges and discover how KINTEK's solutions can enhance your laboratory's capabilities, efficiency, and material integrity.

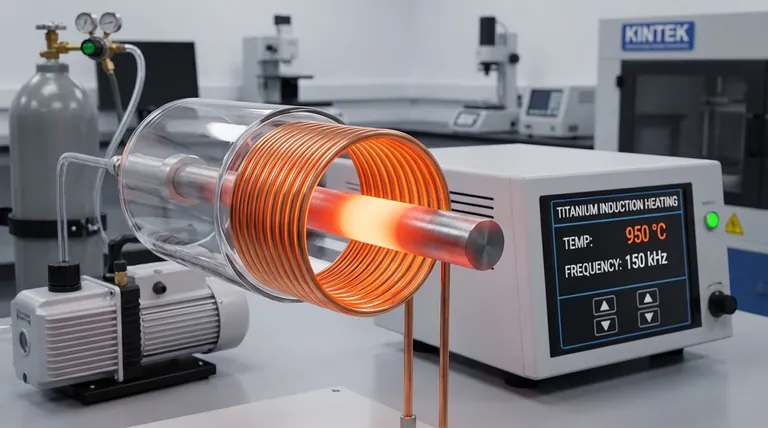

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Anti-Cracking Press Mold for Lab Use

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What frequency is required for induction heating? Match Frequency to Your Heating Depth

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- How to calculate induction heating power? A Guide to Accurate System Sizing

- How arc is produced in vacuum? The Surprising Role of Electrode Material in Plasma Creation

- What is the induction heating method? A Guide to Fast, Clean, and Precise Heating

- What is melt loss? The Ultimate Guide to Reducing Metal Loss in High-Temp Processing

- What is the role of the Vacuum Induction Melting Furnace in AFA steel production? Unlock High-Purity Alloy Precision

- What are the different types of induction furnace? Choose the Right One for Your Melting Needs