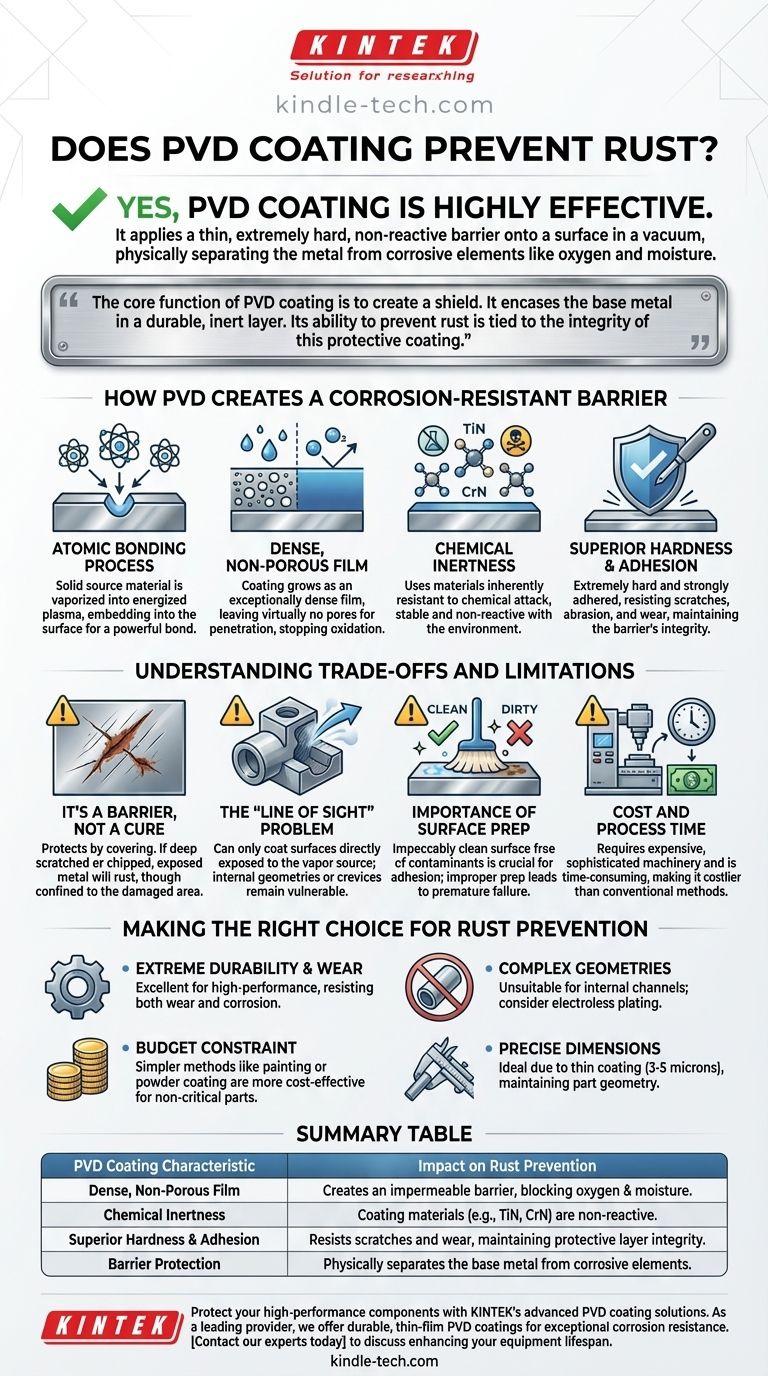

Yes, PVD coating is highly effective at preventing rust. It works by applying a thin, extremely hard, and non-reactive ceramic or metallic film onto a surface in a vacuum. This film acts as an impermeable barrier, physically separating the underlying metal from corrosive elements in the environment, such as oxygen and moisture, which are the primary causes of rust.

The core function of PVD coating is to create a shield. It doesn't change the chemical nature of the base metal; rather, it encases it in a durable, inert layer. Therefore, its ability to prevent rust is directly tied to the integrity and completeness of this protective coating.

How PVD Creates a Corrosion-Resistant Barrier

Physical Vapor Deposition (PVD) is not a simple paint or plating process. It is a high-tech vacuum deposition method that creates a coating with superior characteristics for corrosion protection.

The Atomic Bonding Process

PVD takes place inside a high-vacuum chamber. A solid source material (like titanium, chromium, or zirconium) is vaporized into a plasma of atoms or molecules. These energized particles travel and bombard the component's surface, embedding themselves and forming a powerful, atomically-bonded layer.

Creating a Dense, Non-Porous Film

The high energy of the deposition process ensures the coating grows as an exceptionally dense and uniform film. This density is crucial because it leaves virtually no pores for water or oxygen molecules to penetrate and reach the substrate material underneath. Without access to the base metal, the chemical reaction for rust (oxidation) cannot begin.

Chemical Inertness of the Coating

PVD can be used to deposit materials that are inherently resistant to chemical attack. Coatings like Titanium Nitride (TiN) or Chromium Nitride (CrN) are ceramic compounds that are far more stable and less reactive than the steel or iron they are protecting. They simply do not react with the environment.

Superior Hardness and Adhesion

The resulting coating is not only dense but also extremely hard and strongly adhered to the substrate. This hardness provides excellent resistance to scratches, abrasion, and wear. By preventing mechanical damage, the coating maintains its integrity as a continuous barrier against corrosive elements.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It's a Barrier, Not a Cure

The most important concept to grasp is that PVD provides barrier protection. It protects the metal by covering it. If the coating is deeply scratched, chipped through, or improperly applied, the exposed base metal can and will rust. The rust, however, will typically be confined to the damaged area.

The "Line of Sight" Problem

The PVD process is "line of sight," meaning it can only coat surfaces that are directly exposed to the vapor source within the chamber. Complex internal geometries, deep crevices, or the inside of a tube cannot be effectively coated. These uncoated areas will remain completely vulnerable to rust.

The Importance of Surface Preparation

The success of PVD coating is highly dependent on the condition of the substrate. The surface must be impeccably clean, free of oils, oxides, and any other contaminants. Improper preparation will lead to poor adhesion, causing the coating to fail prematurely and exposing the metal to corrosion.

Cost and Process Time

PVD requires sophisticated and expensive machinery operated by skilled technicians. The process occurs in a vacuum and can be time-consuming, especially for large batches. Consequently, it is significantly more costly than conventional methods like painting or simple electroplating.

Making the Right Choice for Rust Prevention

To decide if PVD is the right choice, evaluate your component's specific needs and operating environment.

- If your primary focus is extreme durability and wear resistance: PVD is an excellent choice, as its hardness simultaneously protects against both mechanical wear and corrosion.

- If you are coating a part with complex internal channels: PVD's line-of-sight nature makes it unsuitable; you may need to consider electroless plating or a different chemical deposition method.

- If your budget is the primary constraint for a non-critical part: Simpler methods like powder coating, painting, or using a corrosion-inhibiting oil are far more cost-effective.

- If you need to maintain precise dimensions and sharp edges: The thin nature of PVD coatings (typically 3-5 microns) is ideal, as it provides protection without altering part geometry.

Ultimately, PVD provides exceptional rust prevention through a robust physical barrier, making it a premier choice for high-performance applications where surface integrity is paramount.

Summary Table:

| PVD Coating Characteristic | Impact on Rust Prevention |

|---|---|

| Dense, Non-Porous Film | Creates an impermeable barrier, blocking oxygen and moisture. |

| Chemical Inertness | Coating materials (e.g., TiN, CrN) are non-reactive with the environment. |

| Superior Hardness & Adhesion | Resists scratches and wear, maintaining the integrity of the protective layer. |

| Barrier Protection | Physically separates the base metal from corrosive elements. |

Protect your high-performance components from rust and wear with KINTEK's advanced PVD coating solutions.

As a leading provider of laboratory equipment and consumables, KINTEK specializes in applying durable, thin-film PVD coatings that provide exceptional corrosion resistance without altering part dimensions. Our coatings are ideal for applications where surface integrity and long-term durability are paramount.

Contact our experts today to discuss how our PVD coating services can enhance the lifespan and performance of your laboratory equipment and precision parts.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Electrolytic Electrochemical Cell for Coating Evaluation

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- Is diamond coating worth it? Maximize Component Life and Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance