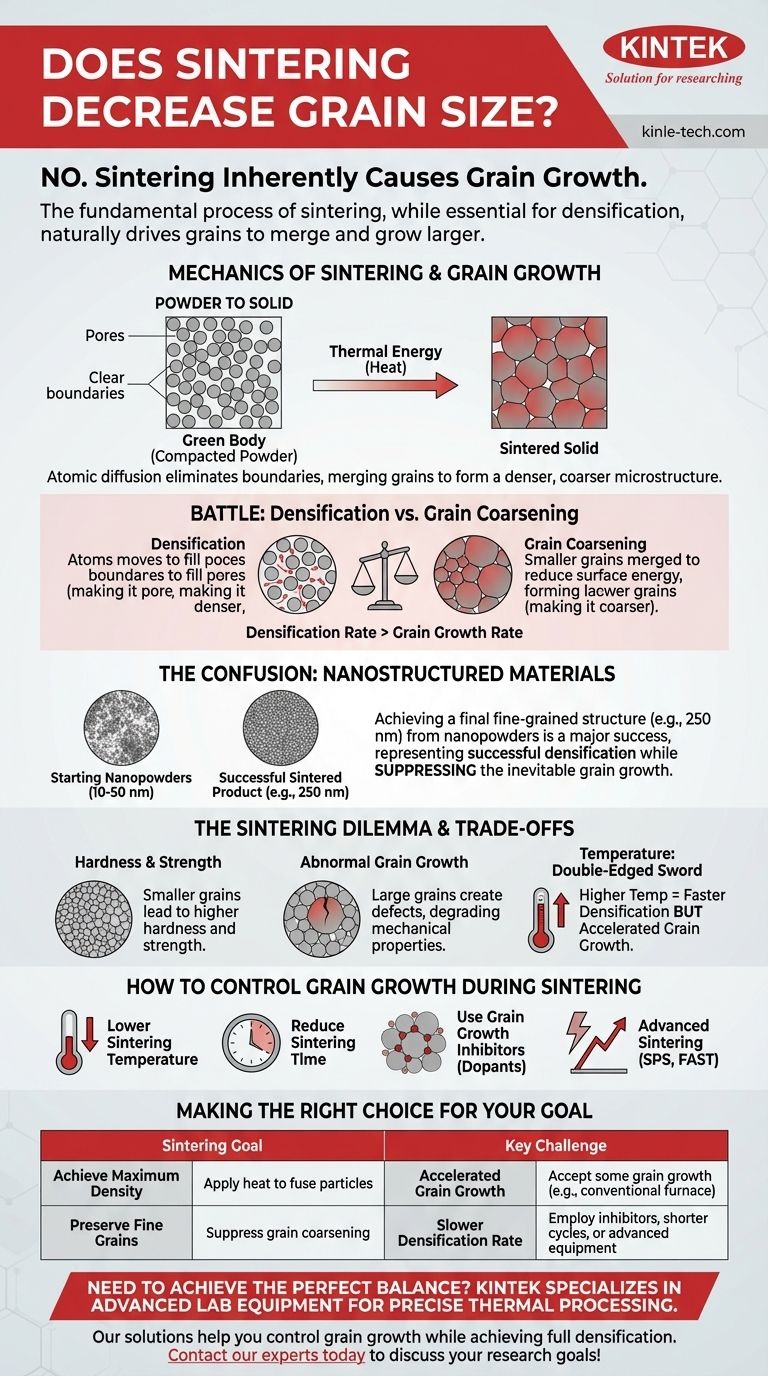

On the contrary, the fundamental process of sintering inherently causes grain growth, leading to an increase in average grain size. Sintering is a thermal treatment used to densify a compacted powder by fusing particles together. This fusion process works by eliminating the boundaries between individual grains, causing them to merge and form larger, more stable grains.

Sintering is a thermal process essential for densifying a material, but it simultaneously drives grain growth. The primary challenge is not to decrease grain size during sintering, but to achieve full density while minimizing the inevitable increase in grain size.

The Mechanics of Sintering and Grain Growth

To understand this process, you must see sintering as a battle between two competing phenomena: the desirable goal of densification and the often undesirable side effect of grain growth.

From Powder to Solid

A material before sintering is typically a "green body"—a compacted collection of individual powder particles. Each particle is a distinct grain, separated by interfaces and pores.

The Role of Thermal Energy

Applying heat provides the energy for atoms to migrate. This atomic diffusion is the engine that drives the entire sintering process, allowing the material to transform from a porous compact into a dense solid.

Minimizing Surface Energy

The universe favors lower energy states. Grain boundaries are high-energy interfaces. By merging, smaller grains reduce the total area of these boundaries, creating a more energetically stable, coarser microstructure. This is the fundamental driving force for grain growth.

Densification vs. Grain Coarsening

Densification occurs as atoms move to fill the pores between particles, making the object denser and stronger. Simultaneously, this atomic movement allows grains to merge and grow. The goal is to have densification happen faster than grain growth.

Why the Confusion? The Goal of Nanostructured Materials

Your question likely stems from work on advanced materials where a final, fine-grained structure is the explicit goal. This can create confusion about the process itself.

Starting with Nanopowders

To create a final product with a nanometer-scale grain structure (e.g., 250 nm), scientists must start with even smaller initial particles, often in the range of 10-50 nm.

The Sintering Success Story

The fact that a material can be sintered and still have a grain size of only 250 nm is considered a major success. It means the engineers successfully densified the material while suppressing the vast majority of the grain growth that would naturally occur.

Understanding the Trade-offs: The Sintering Dilemma

Controlling grain size is critical because it directly dictates the final properties of the material. This creates a constant tension during process design.

Hardness and Strength

For most ceramics and metals, smaller grains lead to higher hardness and strength (a principle known as the Hall-Petch relationship). Fine-grained materials have more grain boundaries, which act as barriers to dislocation movement, making the material harder to deform.

The Cost of Abnormal Grain Growth

As one of your references correctly notes, if a few grains grow disproportionately large, they can create internal stresses and act as defect sites. This "abnormal grain growth" severely degrades mechanical properties like hardness and fracture toughness.

Temperature: A Double-Edged Sword

Higher temperatures accelerate the densification you need. Unfortunately, they also dramatically accelerate the grain growth you want to avoid. Finding the perfect temperature profile is a central challenge in materials engineering.

How to Control Grain Growth During Sintering

Because grain growth is inherent to sintering, a series of strategies are used to manage it and achieve the desired microstructure.

Lowering Sintering Temperature

The most straightforward method is to use the lowest possible temperature that still allows for adequate densification.

Reducing Sintering Time

Minimizing the duration the material spends at peak temperature reduces the time available for atoms to migrate and grains to coarsen.

Using Grain Growth Inhibitors

In some systems, small amounts of a secondary material (a "dopant") are added. These dopants segregate to the grain boundaries and act as a physical drag, "pinning" them in place and slowing their growth.

Advanced Sintering Techniques

Modern methods like Spark Plasma Sintering (SPS) or Field Assisted Sintering Technology (FAST) use electrical currents to heat the material extremely rapidly. This allows for full densification in minutes, before significant grain growth can occur.

Making the Right Choice for Your Goal

Your approach to sintering must be dictated by the end-properties you need to achieve.

- If your primary focus is achieving maximum density: You may need to accept some grain growth by using higher temperatures or longer hold times, especially with conventional furnace sintering.

- If your primary focus is preserving a fine or nano-scale grain structure: You must employ strategies to suppress grain growth, such as using inhibitors, shorter cycles, or advanced sintering equipment.

Ultimately, mastering sintering is about expertly balancing the competing needs of densification and microstructural control.

Summary Table:

| Sintering Goal | Primary Action | Key Challenge |

|---|---|---|

| Achieve Density | Apply heat to fuse particles | Accelerated grain growth |

| Preserve Fine Grains | Suppress grain coarsening | Slower densification rate |

Need to achieve the perfect balance between density and grain size in your lab?

KINTEK specializes in advanced lab equipment and consumables for precise thermal processing. Whether you're working with conventional furnaces or exploring rapid techniques like Spark Plasma Sintering, our solutions help you control grain growth while achieving full densification.

Contact our experts today to discuss how we can support your materials research and production goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results