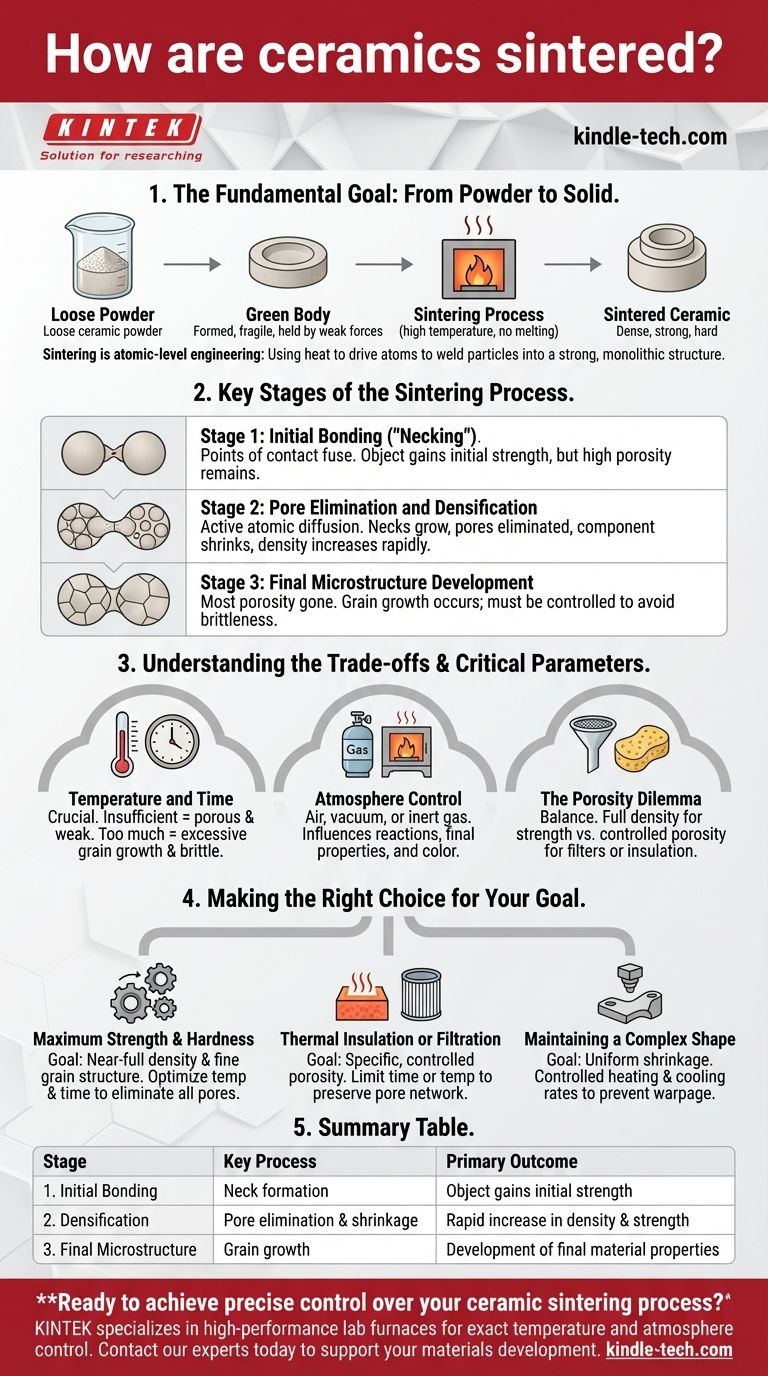

At its core, ceramic sintering is a high-temperature process that transforms a compacted powder into a solid, dense object. It achieves this not by melting the material, but by using heat to force the individual particles to fuse together, eliminating the empty spaces between them. This process is what gives ceramics their characteristic strength, hardness, and stability.

Sintering is fundamentally a process of atomic-level engineering. It uses carefully controlled heat below the material's melting point to drive atoms to move between particles, effectively welding them into a strong, monolithic structure with specific, desired properties.

The Fundamental Goal: From Powder to Solid

The journey from a loose powder to a high-performance ceramic component is defined by the sintering process. It's the critical step that converts a fragile, shaped form into a durable final product.

The Starting Point: The "Green Body"

Before sintering, the ceramic powder is first formed into the desired shape using methods like pressing or casting. This initial, fragile object is known as a "green body." It has the right shape but lacks any meaningful mechanical strength because the particles are only held together by weak forces.

The Driving Force: Heat and Atomic Diffusion

When the green body is heated in a furnace, the atoms within the ceramic particles gain thermal energy. This energy allows them to move, or diffuse, across the boundaries of neighboring particles. This atomic movement is the engine of sintering.

The Result: Densification and Shrinkage

As atoms migrate to fill the gaps and create bonds between particles, the empty spaces (pores) shrink and are gradually eliminated. This causes the entire component to shrink and become significantly more dense. It is this densification that imparts strength, hardness, and other critical properties to the final ceramic part.

The Key Stages of the Sintering Process

Sintering isn't a single event but a progression through distinct stages, each contributing to the final microstructure of the ceramic.

Stage 1: Initial Bonding ("Necking")

In the early stages of heating, the points of contact between individual particles begin to fuse together. This creates small bridges, or "necks," between the particles. The object begins to gain some strength, but porosity is still very high.

Stage 2: Pore Elimination and Densification

As the temperature and time increase, atomic diffusion becomes much more active. The necks between particles grow larger, pulling the particle centers closer together. This is the main stage where pores are eliminated, the component shrinks, and density rapidly increases.

Stage 3: Final Microstructure Development

In the final stage, most of the porosity has been removed. The primary process becomes grain growth, where smaller crystal grains merge to become larger ones. This stage must be carefully controlled, as excessive grain growth can sometimes weaken the final ceramic.

Understanding the Trade-offs and Critical Parameters

Achieving the desired properties in a ceramic is not automatic; it requires precise control over the sintering process. The outcome is a direct result of balancing several critical variables.

Temperature and Time: A Balancing Act

The most crucial parameters are temperature and time. Insufficient heat or time will result in a porous, weak part. However, too much heat or time can lead to excessive grain growth, which can make the ceramic brittle. The ideal cycle is engineered to achieve maximum densification with an optimal final grain size.

Atmosphere Control

The gas atmosphere within the furnace (e.g., air, vacuum, or an inert gas like argon) can significantly influence the outcome. It can prevent unwanted chemical reactions or promote specific ones, directly impacting the material's final properties and even its color.

The Porosity Dilemma

While the goal is often to eliminate all porosity, sometimes a controlled level of porosity is desired for applications like filters or thermal insulation. Expert control over the sintering cycle allows manufacturers to stop the process at the precise point to achieve a specific, targeted density.

Making the Right Choice for Your Goal

Controlling the sintering process allows for the engineering of ceramics tailored for specific applications. The focus of the process changes depending on the primary goal for the final component.

- If your primary focus is maximum strength and hardness: The goal is to achieve near-full density and a fine, uniform grain structure by optimizing the temperature and time to eliminate virtually all pores.

- If your primary focus is thermal insulation or filtration: The goal is to achieve a specific, controlled level of porosity by carefully limiting the sintering time or temperature to preserve a network of interconnected pores.

- If your primary focus is maintaining a complex shape: The goal is to use carefully controlled heating and cooling rates to ensure the part shrinks uniformly, preventing warpage or stress fractures.

Ultimately, mastering the sintering process is what unlocks the vast potential of advanced ceramic materials.

Summary Table:

| Stage | Key Process | Primary Outcome |

|---|---|---|

| 1. Initial Bonding | Neck formation between particles | Object gains initial strength |

| 2. Densification | Pore elimination & shrinkage | Rapid increase in density and strength |

| 3. Final Microstructure | Grain growth | Development of final material properties |

Ready to achieve precise control over your ceramic sintering process? KINTEK specializes in high-performance lab furnaces and consumables designed for exact temperature and atmosphere control. Whether your goal is maximum density for strength or controlled porosity for filtration, our equipment delivers the reliability and precision your laboratory needs. Contact our experts today to discuss how we can support your materials development.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Application

- What is the primary characteristic of a muffle furnace? Unlock Pure, Contamination-Free Heating

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab

- How do you test a metal to determine its quality? Verify Mechanical & Chemical Properties for Your Application

- What are the working principles of furnace? A Guide to Combustion, Resistance, and Induction Heating