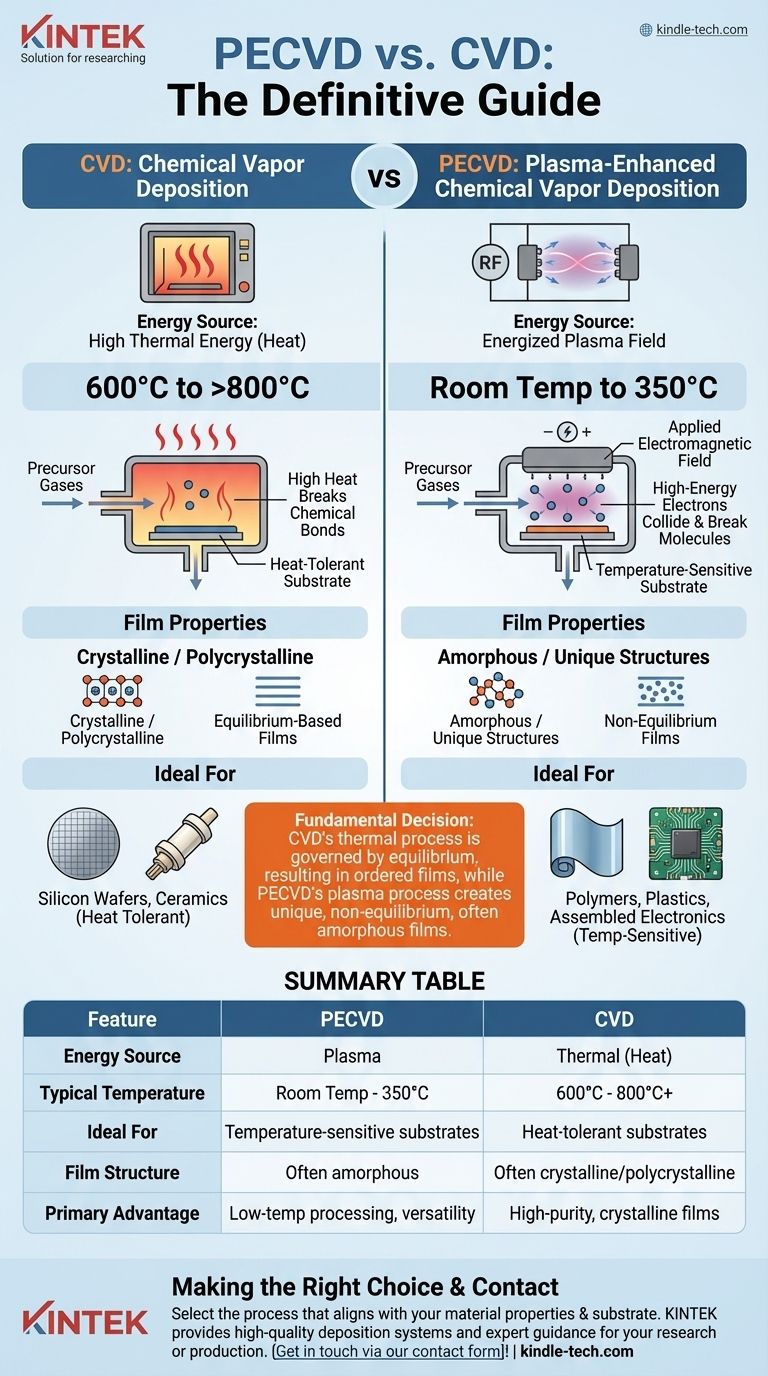

At its core, the difference between PECVD and CVD is how each process provides the energy needed for thin-film deposition. Conventional Chemical Vapor Deposition (CVD) uses high thermal energy—heat—to initiate chemical reactions, typically requiring temperatures from 600°C to over 800°C. In stark contrast, Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses an energized plasma field to break down precursor gases, allowing the process to run at much lower temperatures, often from room temperature to 350°C.

The choice between CVD and PECVD is not merely about temperature; it's a fundamental decision about the resulting film's properties. CVD's thermal process is governed by equilibrium, while PECVD's plasma process creates unique, non-equilibrium films that are often structurally different.

The Fundamental Difference: Energy Source

The method used to activate the chemical reaction dictates the entire process, from the required temperature to the types of materials you can create.

How Thermal CVD Works

In a traditional CVD process, precursor gases are introduced into a chamber where the substrate is heated to very high temperatures.

This intense heat provides the thermal energy required to break the chemical bonds of the gas molecules. The resulting reactive species then deposit onto the hot substrate, forming a solid thin film.

How PECVD Works

PECVD replaces extreme heat with plasma. In this process, an electromagnetic field (typically radio frequency) is applied to the precursor gas at low pressure.

This field energizes the gas into a plasma, a state of matter containing high-energy electrons. These electrons collide with gas molecules, breaking them apart into reactive ions and radicals without needing high temperatures. These reactive species then deposit onto the much cooler substrate.

Why This Matters for the Substrate

The most immediate consequence of this difference is substrate compatibility.

The high temperatures of thermal CVD limit its use to materials that can withstand the heat, such as silicon wafers or ceramics. PECVD's low-temperature nature makes it ideal for coating temperature-sensitive substrates like polymers, plastics, and complex electronic components that would be damaged or destroyed by a thermal process.

The Impact on Film Properties

The energy source doesn't just change the temperature; it fundamentally alters the chemistry of deposition and, therefore, the characteristics of the final film.

Equilibrium vs. Non-Equilibrium Reactions

Thermal CVD operates closer to thermodynamic equilibrium. The reactions are driven by heat in a relatively controlled way, often resulting in highly ordered, dense, and pure films with a crystalline or polycrystalline structure.

The Uniqueness of PECVD Films

PECVD operates in a non-equilibrium state. The high-energy plasma bombards gas molecules indiscriminately, creating a wide range of reactive species.

This allows for the formation of unique film compositions, such as amorphous (non-crystalline) materials, that are not limited by equilibrium kinetics. For example, PECVD is a standard method for depositing amorphous silicon (a-Si:H) and silicon nitride (SiNx) films, whose properties are critical for solar cells and microelectronics.

Understanding the Practical Trade-offs

Choosing a deposition method involves balancing process advantages with potential drawbacks related to your specific application.

Advantage: Temperature & Versatility

PECVD's primary advantage is its low-temperature operation. This vastly expands the range of materials that can be coated, providing design and manufacturing flexibility that is impossible with high-temperature CVD.

Advantage: Deposition Rate

By using plasma to activate the reactants, PECVD can often achieve higher deposition rates at lower temperatures compared to thermal CVD, making it a more efficient process for many industrial applications.

Consideration: Film Quality and Structure

While excellent for amorphous films, PECVD may not be the best choice if the goal is a highly pure, crystalline, or epitaxial layer. The controlled, high-temperature environment of thermal CVD is often superior for producing films with a more perfect crystal structure and lower impurity levels.

Consideration: Process Complexity

A PECVD system is inherently more complex than a basic thermal CVD reactor. It requires additional equipment, including RF power generators and impedance matching networks, to create and sustain the plasma. This can increase the initial cost and maintenance requirements of the equipment.

Making the Right Choice for Your Goal

Your choice depends entirely on the material you are coating and the properties you need in the final film.

- If your primary focus is high-purity, crystalline films on a heat-tolerant substrate: Thermal CVD is often the superior method due to its controlled, equilibrium-based deposition process.

- If your primary focus is coating temperature-sensitive materials like polymers or assembled electronics: PECVD is the necessary choice because its low-temperature operation prevents damage to the substrate.

- If your primary focus is creating unique amorphous films or achieving high deposition rates for industrial throughput: PECVD provides distinct advantages by enabling non-equilibrium reactions that form materials and achieve efficiencies not possible with thermal methods.

Understanding this core difference in energy activation empowers you to select the process that aligns not just with your substrate, but with the fundamental material properties you need to achieve.

Summary Table:

| Feature | PECVD | CVD |

|---|---|---|

| Energy Source | Plasma | Thermal (Heat) |

| Typical Temperature | Room Temp - 350°C | 600°C - 800°C+ |

| Ideal For | Temperature-sensitive substrates (polymers, electronics) | Heat-tolerant substrates (silicon, ceramics) |

| Film Structure | Often amorphous (e.g., a-Si:H) | Often crystalline/polycrystalline |

| Primary Advantage | Low-temperature processing, versatility | High-purity, high-quality crystalline films |

Ready to select the ideal deposition process for your research or production?

The choice between PECVD and CVD is critical for achieving the desired film properties and protecting your substrates. KINTEK specializes in providing high-quality lab equipment, including deposition systems, to meet your specific application needs. Our experts can help you navigate these technical decisions to optimize your results.

Contact us today to discuss your project and discover how our solutions can enhance your laboratory's capabilities. Get in touch via our contact form!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty