To make a hydraulic system more efficient, you must systematically identify and minimize energy losses. The primary sources of this waste are unnecessary heat generation from pressure drops, internal component leakage, and using pumps that deliver more flow than the system requires at a given moment. True efficiency gains come from a holistic approach that includes right-sizing components, optimizing fluid conveyance, and employing intelligent system-level controls.

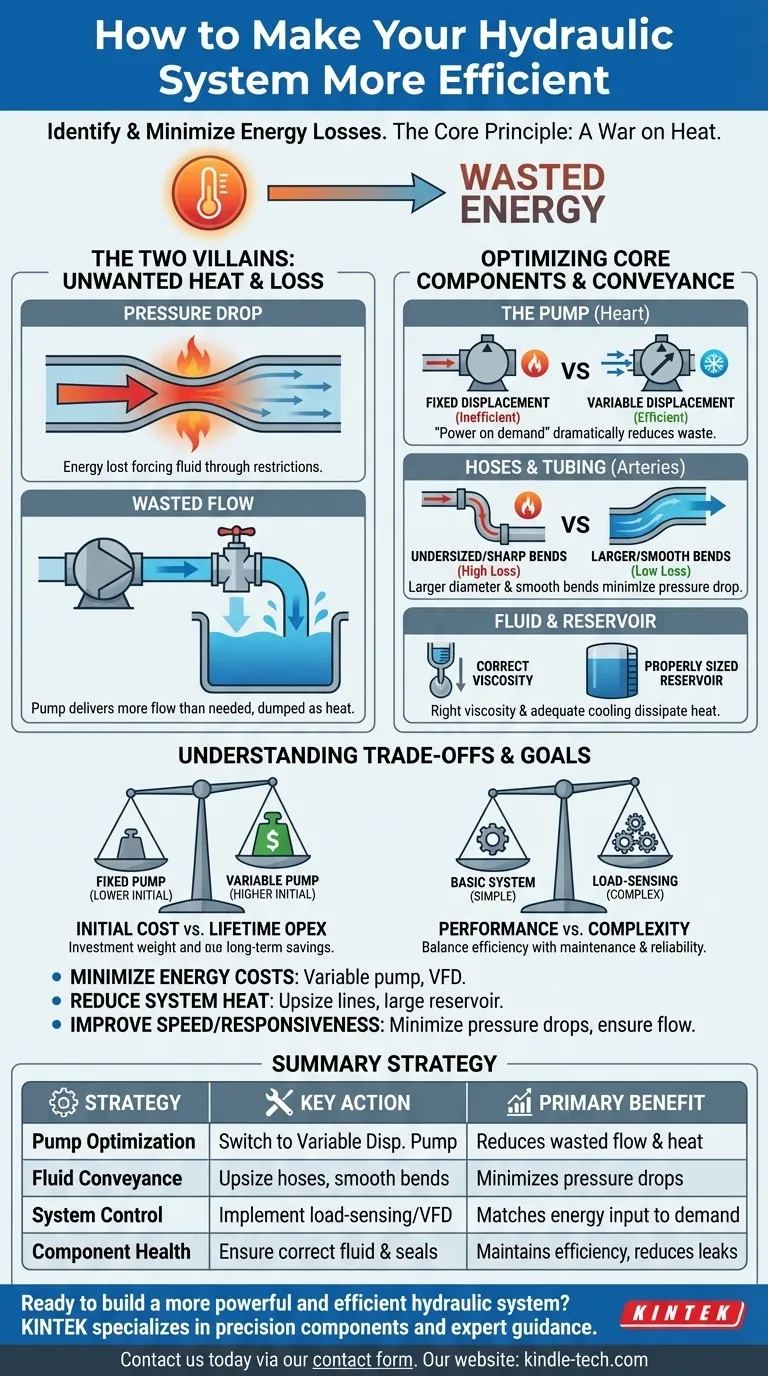

The core principle of hydraulic efficiency is a war on heat. Every watt of wasted energy in your system is converted into heat. Therefore, to increase efficiency, you must find and eliminate every source of unnecessary heat generation.

Diagnosing Inefficiency: Where Is the Energy Going?

Improving efficiency begins with understanding where energy is lost. In hydraulics, wasted energy almost always manifests as heat. An overheating system is, by definition, an inefficient one.

The Primary Symptom: Unwanted Heat

If your reservoir is hot to the touch or your cooler is constantly running, you have a significant efficiency problem. This heat represents energy that was put into the system by the prime mover (electric motor or engine) but did not perform useful work.

The Two Villains: Pressure Drops and Wasted Flow

Energy loss primarily comes from two sources. Pressure drop is the energy lost when fluid is forced through restrictions like undersized hoses, sharp bends, or valves. Wasted flow occurs when the pump produces more flow than the actuators need, forcing the excess oil over a relief valve, which is a massive source of heat.

Optimizing Core Components for Peak Performance

The efficiency of individual components collectively determines the efficiency of the entire system. Selecting the right component for the job is paramount.

The Pump: The Heart of the System

The pump is the single largest factor in a system's efficiency. A fixed displacement pump (like a gear or vane pump) moves a constant volume of oil with every rotation, meaning any unused flow must be dumped over a relief valve, generating heat.

In contrast, a variable displacement piston pump can adjust its output to match the system's demand. This "power on demand" approach dramatically reduces wasted energy, especially in applications with varying cycle times or long hold periods.

Actuators: Sizing and Sealing

Cylinders and hydraulic motors must be sized correctly for the load. An oversized cylinder will be slow and require more flow than necessary, while an undersized one will require higher pressure, stressing the system. Furthermore, worn internal seals allow for fluid bypass, which reduces actuator speed and generates heat.

Valves: Directing Flow with Minimal Loss

Valves, by their nature, create pressure drops. However, modern proportional and servo valves can offer more precise control than simple on/off valves, potentially reducing the need for energy-wasting throttling techniques. Minimizing the number of fittings and sharp turns in the valve manifold also reduces parasitic losses.

The Critical Role of Fluid and Conveyance

How the hydraulic fluid is stored, cleaned, and transported is just as important as the core components it powers.

Hoses and Tubing: The System's Arteries

Forcing fluid through undersized hoses and tubing is like trying to breathe through a coffee straw. It creates significant back pressure and heat. Using larger diameter lines and smooth, sweeping bends instead of sharp fittings dramatically reduces pressure drop and improves overall efficiency.

The Fluid Itself: Viscosity and Cleanliness

Hydraulic fluid with the correct viscosity is crucial. Fluid that is too thick increases friction and requires more energy to pump. Fluid that is too thin can increase internal leakage in components. Keeping the fluid clean with proper filtration prevents premature wear, which maintains the efficiency of pumps and actuators.

The Reservoir: More Than Just a Tank

A properly sized reservoir helps dissipate heat naturally. If the reservoir is too small, the fluid doesn't have enough time to cool and deaerate, leading to a cascading heat problem that may require a larger, energy-consuming cooler to fix.

Understanding the Trade-offs

Pursuing maximum efficiency involves balancing competing priorities. It is essential to understand these compromises to make informed decisions.

Initial Cost vs. Lifetime Operating Cost

High-efficiency components like variable displacement piston pumps and load-sensing valves have a higher upfront cost than their simpler, fixed-displacement counterparts. However, their lower energy consumption can lead to a rapid return on investment through reduced electricity or fuel costs, especially in high-utilization applications.

Performance vs. Complexity

A highly efficient load-sensing system is more complex and can be more difficult to troubleshoot than a basic open-center system with a gear pump. You must balance the desire for peak efficiency with the maintenance capabilities and reliability requirements of your operation.

The Limits of Optimization

No hydraulic system can be 100% efficient. There will always be some mechanical friction and fluid losses. The goal is not to achieve impossible perfection but to eliminate unnecessary and avoidable waste.

Making the Right Choice for Your Goal

Your strategy should be guided by your primary objective. Different goals demand different solutions.

- If your primary focus is minimizing energy costs: Invest in a variable displacement pump and consider a Variable Frequency Drive (VFD) for the electric motor to precisely match energy input to workload.

- If your primary focus is reducing system heat: Upsize your hydraulic lines, use smooth bends, and ensure your reservoir is large enough to provide adequate passive cooling.

- If your primary focus is improving machine speed and responsiveness: Minimize pressure drops in every part of the circuit and ensure your pump and valves can deliver the instantaneous flow your actuators demand.

By methodically addressing the sources of energy loss, you can build a hydraulic system that is not only powerful but also remarkably efficient.

Summary Table:

| Strategy | Key Action | Primary Benefit |

|---|---|---|

| Pump Optimization | Switch to a variable displacement piston pump | Reduces wasted flow and heat generation |

| Fluid Conveyance | Upsize hoses and use smooth bends | Minimizes pressure drops and energy loss |

| System Control | Implement load-sensing or VFD controls | Matches energy input to actual demand |

| Component Health | Ensure correct fluid viscosity and seal integrity | Maintains peak component efficiency and reduces leakage |

Ready to build a more powerful and efficient hydraulic system?

KINTEK specializes in the precision components and expert guidance needed to optimize your lab's hydraulic equipment. By partnering with us, you can achieve significant energy savings, reduce operational heat, and extend the life of your machinery.

Contact us today via our contact form to discuss how our solutions can be tailored to your specific laboratory needs and drive your efficiency goals forward.

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Lab Heat Press

- Variable Speed Peristaltic Pump

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What is a hydraulic hot press? Unlock the Power of Heat and Pressure for Advanced Materials

- How does a hydraulic hot press machine work? Unlock Precision in Material Bonding and Forming

- What is the role of a hydraulic press with heating plates in copper welding tests? Analyze Stress & Thermal Cycles