To prevent short circuits in an electrolytic cell, you must ensure there is no direct physical contact between the electrodes themselves, or between an electrode and the conductive body of the cell. A short circuit creates an unintended, low-resistance path for electricity, bypassing the electrolyte and leading to a dangerous surge in current.

The core principle of preventing a short circuit is maintaining the intended electrical path. Electricity must be forced to travel through the electrolyte to drive the chemical reaction, not find a "shortcut" through direct contact between conductive components.

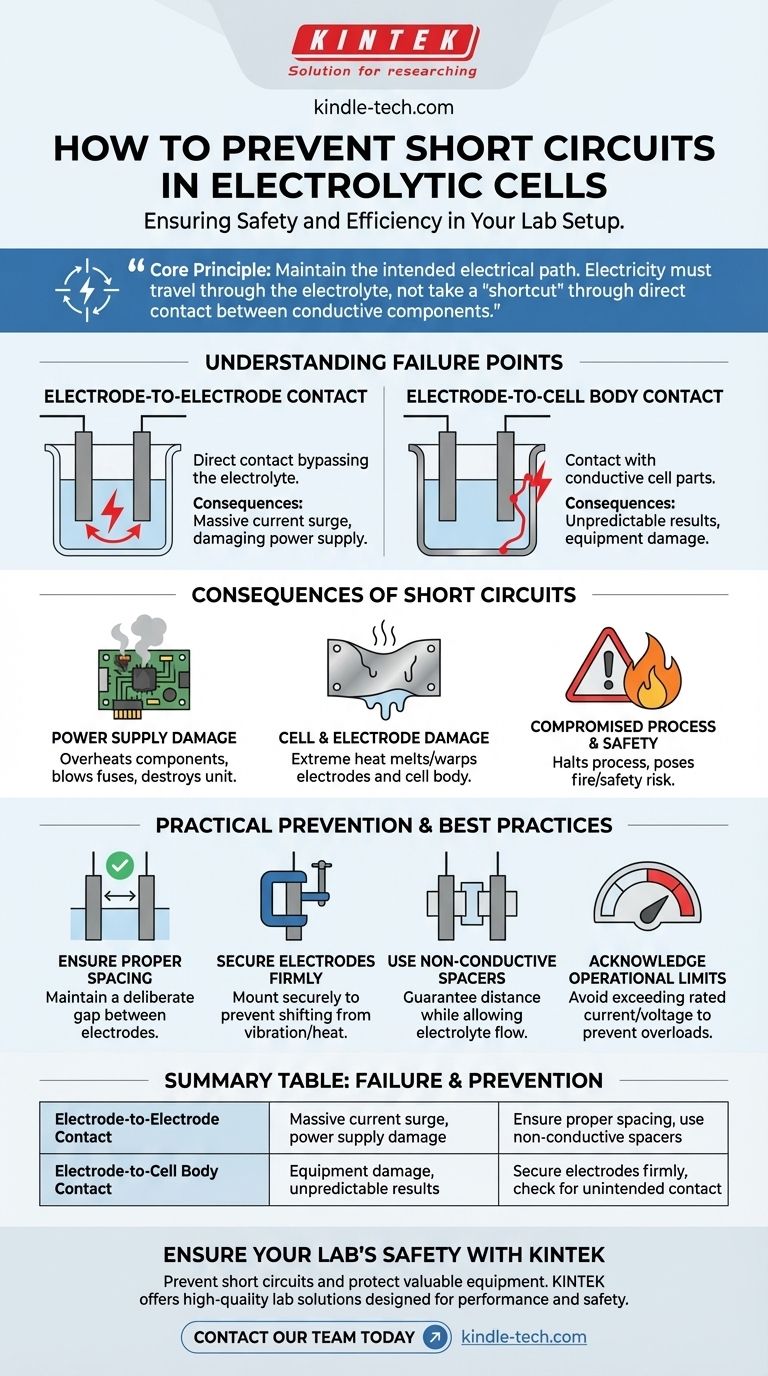

Understanding the Failure Points

A short circuit is fundamentally a problem of unintended connections. In an electrolytic cell, this happens in two primary ways, both of which bypass the intended process.

Electrode-to-Electrode Contact

This is the most direct type of short circuit. When the anode and cathode touch, electricity flows directly between them without resistance.

The power supply sees this as an extremely low-resistance path, causing it to deliver a massive, potentially damaging amount of current.

Electrode-to-Cell Body Contact

This is a more subtle but equally critical failure. If an electrode touches a conductive part of the cell's tank or body, it can create an alternative path for the current.

This can either short the cell directly or bypass certain sections, leading to equipment damage and unpredictable results.

Why Preventing Short Circuits is Critical

The consequences of a short circuit are immediate and severe. Understanding them highlights the importance of a proper and secure setup.

Damage to the Power Supply

A short circuit will cause the power supply to draw a surge of current far beyond its operational limits. This can overheat components, blow fuses, or permanently destroy the unit.

Damage to the Cell and Electrodes

The intense current flowing through the point of contact generates extreme heat. This can melt or warp the electrodes and damage the lining or body of the electrolytic cell itself.

Compromised Process and Safety

A short circuit halts the desired electrolytic process entirely. The uncontrolled release of energy also poses a significant safety hazard, including the risk of fire or damage to surrounding equipment.

Practical Prevention and Best Practices

Preventing these failures requires a disciplined approach to the physical setup of your cell. It's not just about placement, but also about securing that placement.

Ensure Proper Spacing

Always maintain a deliberate and sufficient gap between the anode and cathode. This distance is critical not only for preventing shorts but also for the efficiency of the electrolytic process.

Secure Electrodes Firmly

Electrodes must be mounted securely so they cannot shift, bend, or fall during operation. Vibrations or thermal expansion can cause components to move unexpectedly.

Consider Using Non-Conductive Spacers

In some designs, non-conductive spacers or separators can be used to guarantee that electrodes maintain their distance. These materials physically prevent contact while still allowing the electrolyte to circulate.

Acknowledge Operational Limits

While not a direct cause of a short circuit, exceeding the rated current or voltage of your equipment creates an overload condition. This also risks damaging the power supply and the cell, and it reduces your margin of safety.

Key Principles for Your Setup

Your approach should be guided by the fundamental goal of controlling the electrical path.

- If your primary focus is equipment safety: Your first and most important check is confirming the absolute physical separation of all conductive components (electrodes and cell body).

- If your primary focus is reliable results: Ensure that the only path for current to flow between electrodes is through the electrolyte, as this is essential for the chemical reaction to proceed correctly.

A secure and correctly spaced setup is the foundation of a safe and effective electrolytic process.

Summary Table:

| Failure Point | Consequence | Prevention Method |

|---|---|---|

| Electrode-to-Electrode Contact | Massive current surge, power supply damage | Ensure proper spacing, use non-conductive spacers |

| Electrode-to-Cell Body Contact | Equipment damage, unpredictable results | Secure electrodes firmly, check for unintended contact |

Ensure your lab's electrolytic processes are safe and efficient with KINTEK.

Preventing short circuits is critical for protecting your valuable equipment and achieving reliable results. KINTEK specializes in high-quality lab equipment and consumables designed for safety and performance. Our experts can help you select the right components for a secure setup.

Contact our team today to discuss your laboratory needs and discover how our solutions can enhance your workflow.

Visual Guide

Related Products

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Thin-Layer Spectral Electrolysis Electrochemical Cell

People Also Ask

- What is the proper procedure for post-experiment cleanup and storage of an all-quartz electrolytic cell? Ensure Longevity and Reproducibility

- What are the primary applications of the all-quartz electrolytic cell? Essential for High-Purity & Optical Analysis

- What are the operational procedures and safety precautions during an experiment using an all-quartz electrolytic cell? Ensure Safety and Accuracy in Your Lab

- What materials are used to construct the all-quartz electrolytic cell? A Guide to Purity and Performance

- What precautions should be taken when handling and using an all-quartz electrolytic cell? Ensure Safe, Accurate, and Durable Performance