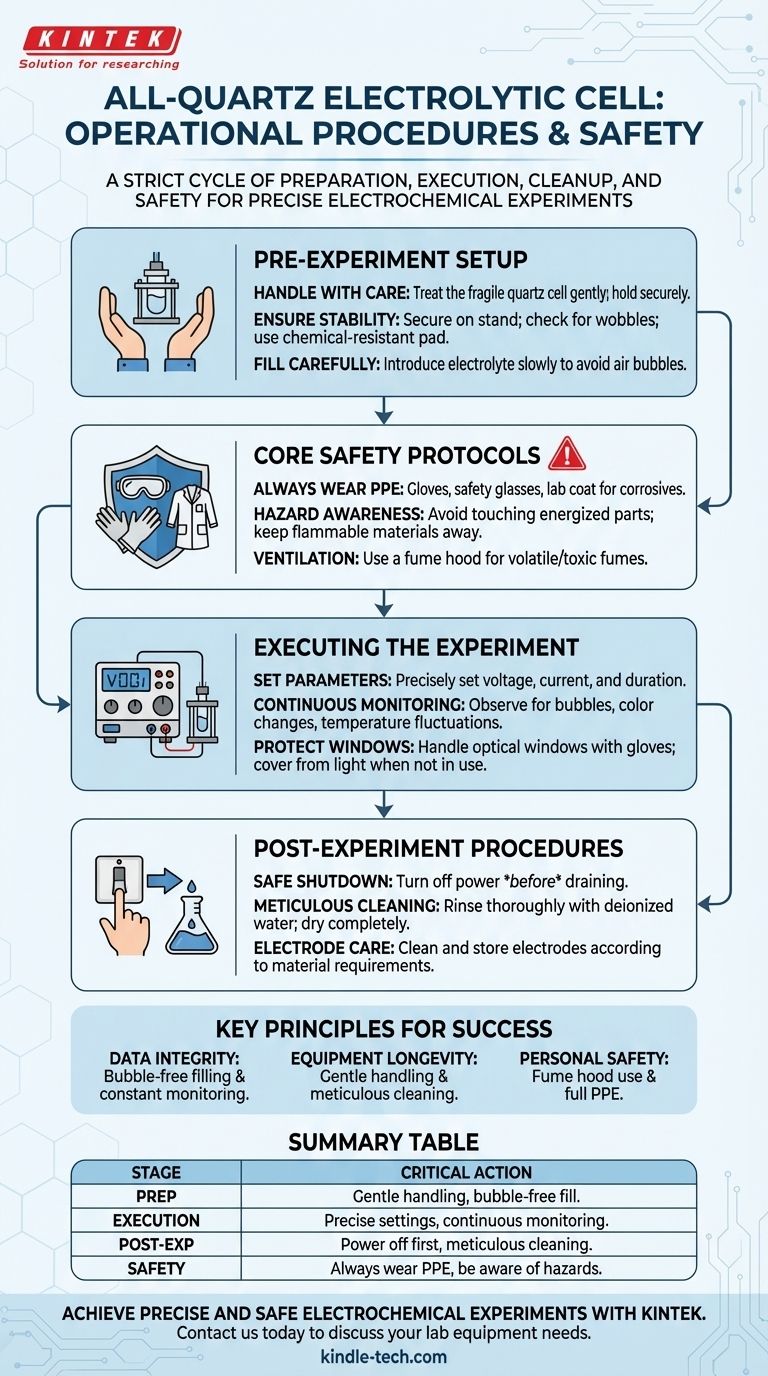

To properly operate an all-quartz electrolytic cell, you must follow a strict sequence of procedures covering preparation, execution, and cleanup. The core process involves carefully filling the cell, setting precise electrical parameters, continuously monitoring for abnormalities, and performing a meticulous cleaning routine afterward, all while adhering to rigorous safety protocols to manage chemical and electrical hazards.

The key to successful and safe experimentation is treating the process not as a checklist, but as a continuous cycle of observation and care. Your respect for the fragile equipment and hazardous materials is directly linked to the quality of your results and your personal safety.

Pre-Experiment Setup and Preparation

Before any current is applied, the foundation for a successful experiment is laid. Proper setup prevents equipment damage and ensures the stability required for accurate measurements.

Handling the Quartz Cell Body

The cell body is made of quartz or glass, making it extremely fragile. It must be handled gently at all times.

Always hold the cell securely with both hands and avoid setting it down on hard surfaces where it could be knocked over.

Ensuring Stability

Position the electrolytic cell on the stand's base and firmly tighten the fixing knobs. This ensures the cell remains perfectly vertical and does not wobble during the experiment, which is critical for consistent electrode immersion.

If you are using corrosive electrolytes, place a chemical-resistant, leak-proof pad under the cell as a secondary containment measure.

Filling the Cell

Slowly and carefully introduce the prepared electrolyte into the cell. The goal is to avoid introducing air bubbles, which can cling to electrode surfaces and interfere with accurate current density and electrochemical measurements.

Core Safety Protocols

Safety is not a single step but a constant state of awareness. All-quartz electrolytic cells often involve the combination of electricity, corrosive chemicals, and fragile glassware.

Personal Protective Equipment (PPE)

When working with corrosive electrolytes, always wear appropriate protective gloves and safety glasses. A lab coat is standard to protect against splashes.

Electrical and Fire Hazards

Never touch the electrodes or electrolyte with bare hands during operation to prevent severe electric shock.

Keep the area around the electrolytic cell clear of open flames or other flammable materials. The electrolysis of certain solutions can produce flammable gases (like hydrogen), creating a potential fire or explosion hazard.

Chemical Hazards and Ventilation

When using volatile or toxic electrolytes, or if the reaction produces harmful gases, the entire operation must be conducted inside a functioning fume hood. This prevents the inhalation of hazardous fumes.

Executing the Experiment

With the cell prepared and safety measures in place, you can proceed with the experiment itself. This phase requires precision and constant observation.

Setting Electrolysis Parameters

Set the required electrolysis parameters on your power supply, such as voltage, current, and duration. These settings must be chosen carefully based on the specific goals of your experiment.

Continuous Monitoring

Closely monitor the phenomena inside the cell throughout the experiment. Pay attention to bubble formation on the electrode surfaces, any changes in the electrolyte's color, or fluctuations in temperature.

If you observe any abnormalities, be prepared to stop the experiment immediately to diagnose the issue.

Protecting Optical Windows

If your cell has optical windows for spectroelectrochemistry, they require special care. Avoid touching the windows with bare hands; always wear gloves.

If a window becomes stained, clean it only with a dedicated optical cleaning solution and lens paper. When not in use, turn off the light source or cover the cell with a light shield to prevent the window material from degrading under prolonged light exposure.

Post-Experiment Procedures

Proper shutdown and cleaning are not just about tidiness; they are essential for preventing cross-contamination in future experiments and ensuring the longevity of the expensive cell and electrodes.

Safe Shutdown and Draining

First, turn off the power supply completely. Only then should you drain the electrolyte from the cell. Dispose of the waste electrolyte according to your institution's environmental and safety regulations.

Meticulous Cleaning

Thoroughly clean the cell with deionized water or another appropriate solvent to remove all residual impurities. Rinsing multiple times is crucial.

After cleaning, dry the cell completely, often with a gentle stream of filtered nitrogen or clean air.

Electrode Care and Storage

Carefully remove the electrodes from the cell. Clean them according to their specific material requirements and store them properly. Electrodes that are susceptible to oxidation or corrosion may need special protective measures, such as being stored in a protective solution or a desiccator.

Key Principles for Reliable Results

Your specific actions should be guided by your ultimate goal.

- If your primary focus is data integrity: Prioritize bubble-free filling and constant monitoring to ensure your experimental conditions remain stable and your measurements are accurate.

- If your primary focus is equipment longevity: Emphasize gentle handling of the quartz cell, meticulous cleaning of optical windows, and proper electrode care to prevent damage and contamination.

- If your primary focus is personal safety: Always operate within a fume hood when necessary, wear correct PPE, and remain vigilant about the dual risks of electricity and corrosive chemicals.

Mastering this equipment comes from a disciplined approach that respects the science, the materials, and the potential hazards.

Summary Table:

| Stage | Key Focus | Critical Action |

|---|---|---|

| Preparation | Equipment Integrity & Stability | Handle quartz cell gently; secure on stand; fill electrolyte slowly to avoid bubbles. |

| Execution | Data Integrity & Hazard Control | Set precise electrical parameters; monitor continuously; operate in fume hood if needed. |

| Post-Experiment | Equipment Longevity & Safety | Shut down power first; drain and dispose of waste properly; clean and dry cell meticulously. |

| Safety | Personal Protection | Always wear PPE (gloves, glasses, lab coat); be aware of electrical and chemical hazards. |

Achieve precise and safe electrochemical experiments with KINTEK.

Our specialized lab equipment, including durable electrolytic cells, is designed to meet the rigorous demands of your research. Whether you prioritize data integrity, equipment longevity, or personnel safety, KINTEK provides reliable solutions tailored to your laboratory's needs.

Contact us today via our [#ContactForm] to discuss how our products can enhance your experimental workflows and ensure consistent, high-quality results.

Visual Guide

Related Products

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Electrolytic Electrochemical Cell with Five-Port

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- What are the standard opening specifications for sealed and unsealed all-quartz electrolytic cells? Optimize Your Electrochemistry Setup

- What are the available volumes and dimensions for the all-quartz electrolytic cell? Find the Perfect Fit for Your Lab

- What is the proper procedure for post-experiment cleanup and storage of an all-quartz electrolytic cell? Ensure Longevity and Reproducibility

- What are the primary applications of the all-quartz electrolytic cell? Essential for High-Purity & Optical Analysis

- What materials are used to construct the all-quartz electrolytic cell? A Guide to Purity and Performance