Proper cleanup of an all-quartz electrolytic cell is a systematic process that ensures the longevity of your equipment and the integrity of future experiments. The correct procedure involves powering down the system, immediately draining the electrolyte, performing a multi-stage rinse with appropriate solvents, carefully handling the electrodes, and drying the cell completely before storage.

The goal of post-experiment cleanup is not merely to make the cell look clean. It is a critical scientific practice designed to prevent cross-contamination, protect a significant financial investment, and guarantee the reproducibility of your results.

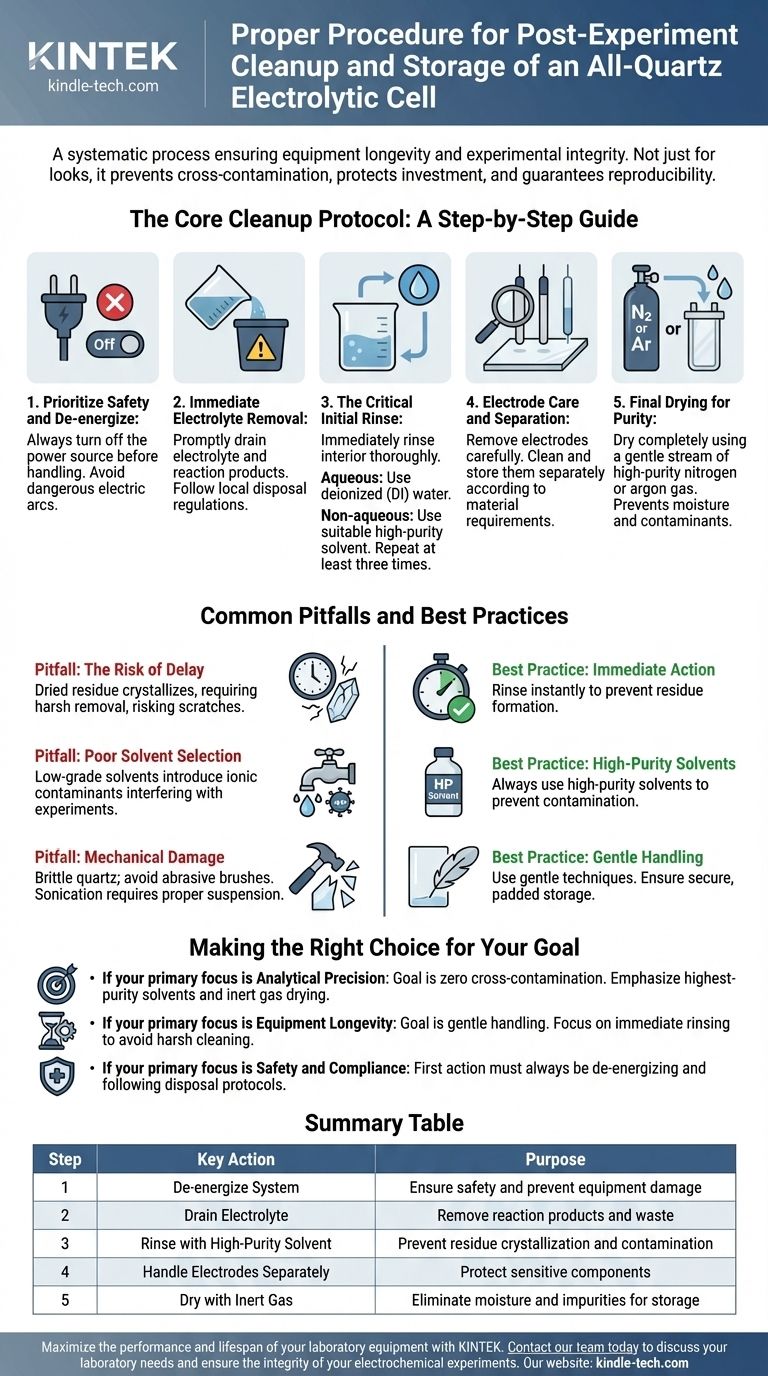

The Core Cleanup Protocol: A Step-by-Step Guide

Following a consistent procedure is the most effective way to maintain the performance and condition of your all-quartz cell. Each step serves a specific purpose in removing contaminants and preserving the delicate material.

Step 1: Prioritize Safety and De-energize

Before any handling, always turn off the power source connected to the cell. Disconnecting a live cell can cause dangerous electric arcs and damage your equipment. This is the non-negotiable first step.

Step 2: Immediate Electrolyte Removal

Promptly drain all electrolyte and reaction products from the cell. Waste liquids must be handled and disposed of according to your laboratory's safety protocols and local environmental regulations.

Step 3: The Critical Initial Rinse

Immediately after draining, rinse the cell interior thoroughly. For aqueous experiments, use deionized (DI) water. For non-aqueous systems, use a suitable high-purity solvent.

This immediate rinse is crucial. It prevents residual salts and reaction byproducts from drying and crystallizing on the quartz surface, which can be extremely difficult to remove later. A common best practice is to perform at least three initial rinses.

Step 4: Electrode Care and Separation

Carefully remove the reference, counter, and working electrodes from the cell. Clean and store them separately according to their specific material requirements. Electrodes are often more sensitive than the cell and require their own dedicated care routine.

Step 5: Final Drying for Purity

Dry the cell completely using a gentle stream of high-purity nitrogen or argon gas. Using an inert gas is superior to compressed air, as it prevents the introduction of moisture, particulates, or other atmospheric contaminants. Proper drying eliminates water spots that can contain trace impurities.

Common Pitfalls and Best Practices

Understanding the reasoning behind the procedure helps prevent common mistakes that can compromise your cell.

The Risk of Delay: Dried Residue

The single biggest mistake is waiting to clean the cell. When electrolyte dries, crystals can form and adhere strongly to the quartz. Removing this residue may require harsh acids or mechanical scrubbing, increasing the risk of scratching or damaging the cell.

Solvent Selection: Purity is Paramount

Always use high-purity solvents for cleaning. Using tap water or low-grade solvents can introduce ionic contaminants (like chloride, sodium, or calcium) that adsorb onto the quartz surface and can interfere with subsequent experiments.

The Danger of Mechanical Damage

All-quartz cells are brittle and susceptible to thermal shock and scratches. Avoid using abrasive brushes. If sonication is necessary for stubborn residues, ensure the cell is properly suspended in the ultrasonic bath and not resting directly on the bottom, which can cause cracking from the vibration.

Making the Right Choice for Your Goal

Your specific experimental needs will determine which part of the process to emphasize.

- If your primary focus is analytical precision: Your goal is zero cross-contamination. Emphasize using the highest-purity solvents and drying thoroughly with inert gas.

- If your primary focus is equipment longevity: Your priority is gentle handling. Focus on immediate rinsing to avoid the need for harsh cleaning methods later and ensure secure, padded storage.

- If your primary focus is safety and compliance: Your first actions must always be de-energizing the system and meticulously following protocols for waste electrolyte disposal.

This disciplined approach transforms cell cleanup from a chore into a cornerstone of reliable and reproducible electrochemical research.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | De-energize System | Ensure safety and prevent equipment damage |

| 2 | Drain Electrolyte | Remove reaction products and waste |

| 3 | Rinse with High-Purity Solvent | Prevent residue crystallization and contamination |

| 4 | Handle Electrodes Separately | Protect sensitive components |

| 5 | Dry with Inert Gas | Eliminate moisture and impurities for storage |

Maximize the performance and lifespan of your laboratory equipment with KINTEK.

Proper cleanup is essential for reliable results. KINTEK specializes in high-purity lab equipment and consumables, including all-quartz electrolytic cells and the high-purity solvents needed to maintain them. Our experts can help you select the right products and establish best practices for your specific research goals.

Contact our team today to discuss your laboratory needs and ensure the integrity of your electrochemical experiments.

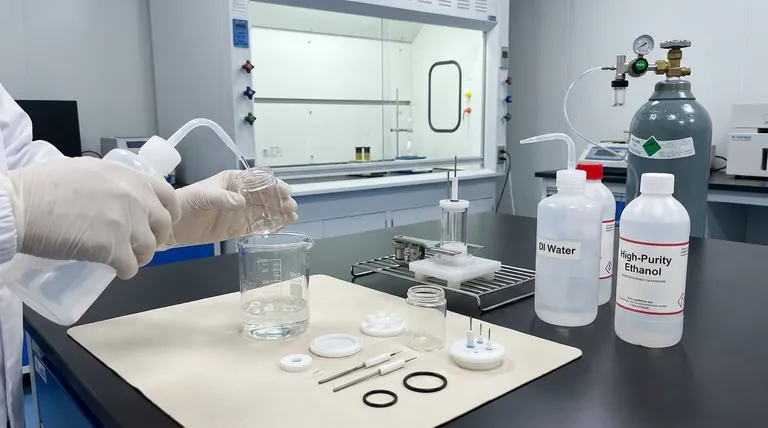

Visual Guide

Related Products

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Electrolytic Electrochemical Cell with Five-Port

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- H Type Electrolytic Cell Triple Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

People Also Ask

- How should an all-quartz electrolytic cell and its components be maintained for long-term use? A Guide to Maximizing Equipment Lifespan

- What are the necessary steps to prepare an all-quartz electrolytic cell before an experiment? Ensure Accuracy and Safety

- What are the operational procedures and safety precautions during an experiment using an all-quartz electrolytic cell? Ensure Safety and Accuracy in Your Lab

- What are the available volumes and dimensions for the all-quartz electrolytic cell? Find the Perfect Fit for Your Lab

- What are the standard opening specifications for sealed and unsealed all-quartz electrolytic cells? Optimize Your Electrochemistry Setup