To choose the right hydraulic press, you must first define your core operational needs. The selection process hinges on three primary factors: the maximum force (tonnage) your application requires, the physical size of your workpiece and the press itself, and any special features dictated by your process, such as heating or automation.

The most common mistake is choosing a press based on its maximum possible force. The correct approach is to select a press where your typical working force falls comfortably within its recommended operating range, ensuring longevity, accuracy, and safety.

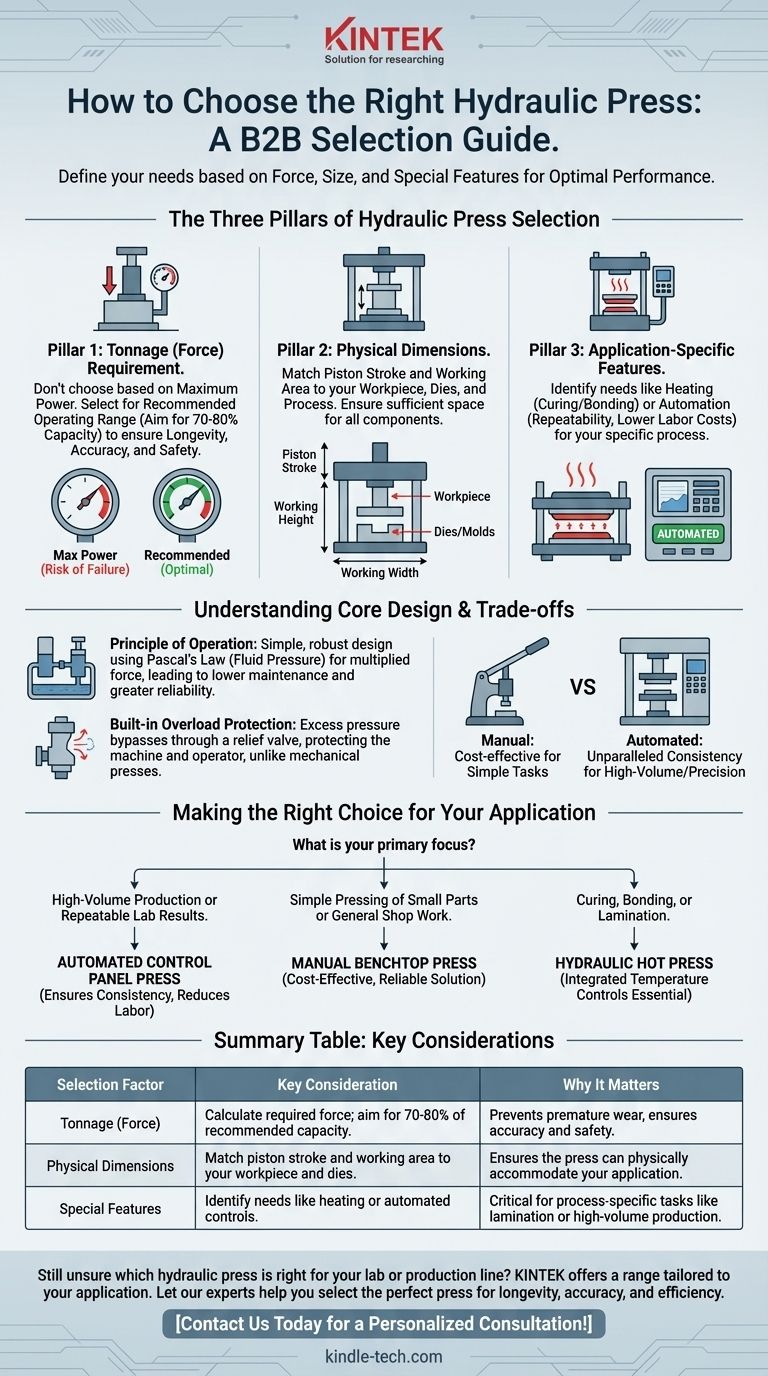

The Three Pillars of Hydraulic Press Selection

Your decision should be a methodical evaluation of your specific task against the machine's capabilities. We can break this down into three fundamental areas.

Pillar 1: Calculating Your Tonnage (Force) Requirement

This is the single most important specification. Tonnage is the amount of force the press can generate.

Manufacturers often provide two ratings: a maximum allowed power and a maximum recommended power. For example, a press might be rated for a 15-ton absolute maximum but have a recommended limit of 9.5 tons.

Operating a press consistently at its absolute maximum limit leads to premature wear and potential failure. A professional always selects a press where the required working force is around 70-80% of the recommended capacity.

Pillar 2: Matching Physical Dimensions to Your Work

The press must physically accommodate your workpiece and the process you intend to perform.

Key dimensions include the piston stroke, which is the maximum distance the ram can travel. A 25mm stroke, for instance, is suitable for compressing pellets or shallow forming, but not for deep drawing operations.

You must also consider the overall working area—the height and width available between the ram and the press bed. Ensure your dies, molds, and workpieces will fit comfortably within this space.

Pillar 3: Identifying Application-Specific Features

Not all presses are created equal. The process dictates the features you need.

A hydraulic hot press, for example, is essential for applications like lamination, curing, or bonding. These units integrate heating systems and specialized controls to manage temperature accurately across each layer.

For production environments, look for an automated control panel. This ensures repeatability, reduces the chance for operator error, and can significantly lower labor costs by allowing a single person to manage the machine safely.

Understanding the Trade-offs and Core Design

A hydraulic press operates on a simple, robust principle that gives it distinct advantages and certain considerations to keep in mind.

The Principle of Operation: Simplicity and Power

At its core, a hydraulic press uses two interconnected cylinders filled with fluid. When force is applied to the small cylinder (the plunger), Pascal's Law dictates that pressure is transmitted equally throughout the fluid, generating an immense, multiplied force in the large cylinder (the ram).

This simple design requires fewer parts than mechanical presses, which contributes to lower maintenance, greater reliability, and a longer lifespan for both the machine and the tooling.

The Advantage of Built-in Overload Protection

A major inherent benefit of hydraulic systems is their natural overload protection. Unlike a mechanical press, which can catastrophically fail or break if its force limit is exceeded, a hydraulic press will simply bypass excess pressure through a relief valve.

This feature not only protects the machine from damage but also serves as a critical safety function for the operator.

Manual vs. Automated Control

The choice between a manual lever-operated press and one with an automated control panel is a primary trade-off between cost and capability.

Manual presses are less expensive and ideal for one-off jobs or simple tasks. Automated presses provide unparalleled consistency, making them essential for any process where precise, repeatable pressure and timing are critical.

Making the Right Choice for Your Application

Answering the following questions will guide you to the correct hydraulic press for your specific goals.

- If your primary focus is high-volume production or repeatable lab results: Prioritize a press with an automated control panel to ensure process consistency and reduce labor.

- If your primary focus is simple pressing of small parts or general shop work: A basic, manual benchtop press offers a cost-effective and reliable solution.

- If your primary focus is curing, bonding, or lamination: A specialized hydraulic hot press with integrated temperature controls is non-negotiable.

Ultimately, selecting the right hydraulic press is a matter of precisely matching the machine’s capabilities to the demands of your specific task.

Summary Table:

| Selection Factor | Key Consideration | Why It Matters |

|---|---|---|

| Tonnage (Force) | Calculate required force; aim for 70-80% of press's recommended capacity. | Prevents premature wear and ensures accuracy and safety. |

| Physical Dimensions | Match piston stroke and working area to your workpiece and dies. | Ensures the press can physically accommodate your specific application. |

| Special Features | Identify needs like heating (for curing/bonding) or automated controls. | Critical for process-specific tasks like lamination or high-volume production. |

Still unsure which hydraulic press is right for your lab or production line?

KINTEK specializes in lab equipment and consumables, offering a range of hydraulic presses tailored to your specific application—from manual benchtop models for simple tasks to fully automated hot presses for precise curing and bonding.

Let our experts help you select the perfect press to ensure longevity, accuracy, and efficiency in your operations. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the advantage of hydraulic press over mechanical press? Superior Control, Lower Cost & Built-in Protection

- What is the function of laboratory hydraulic presses in leaching residue prep? Master SEM Sample Precision

- Significance of High Pressure in Lab Hydraulic Press for 304L Steel Green Compacts: Achieve 750 MPa Densification

- Is a hydraulic press safe? How to Mitigate Crushing, Injection, and Failure Risks

- How often do hydraulics need maintenance? A Guide to Condition-Based Reliability

- What is the operating temperature of a standard hydraulic system? Achieve Peak Efficiency and Longevity

- What is the primary purpose of using a laboratory hydraulic press? Optimize Aluminum Matrix Composite Preparation

- What is the pellet technique used in IR for? Creating Clear, Transparent Samples for Accurate Analysis