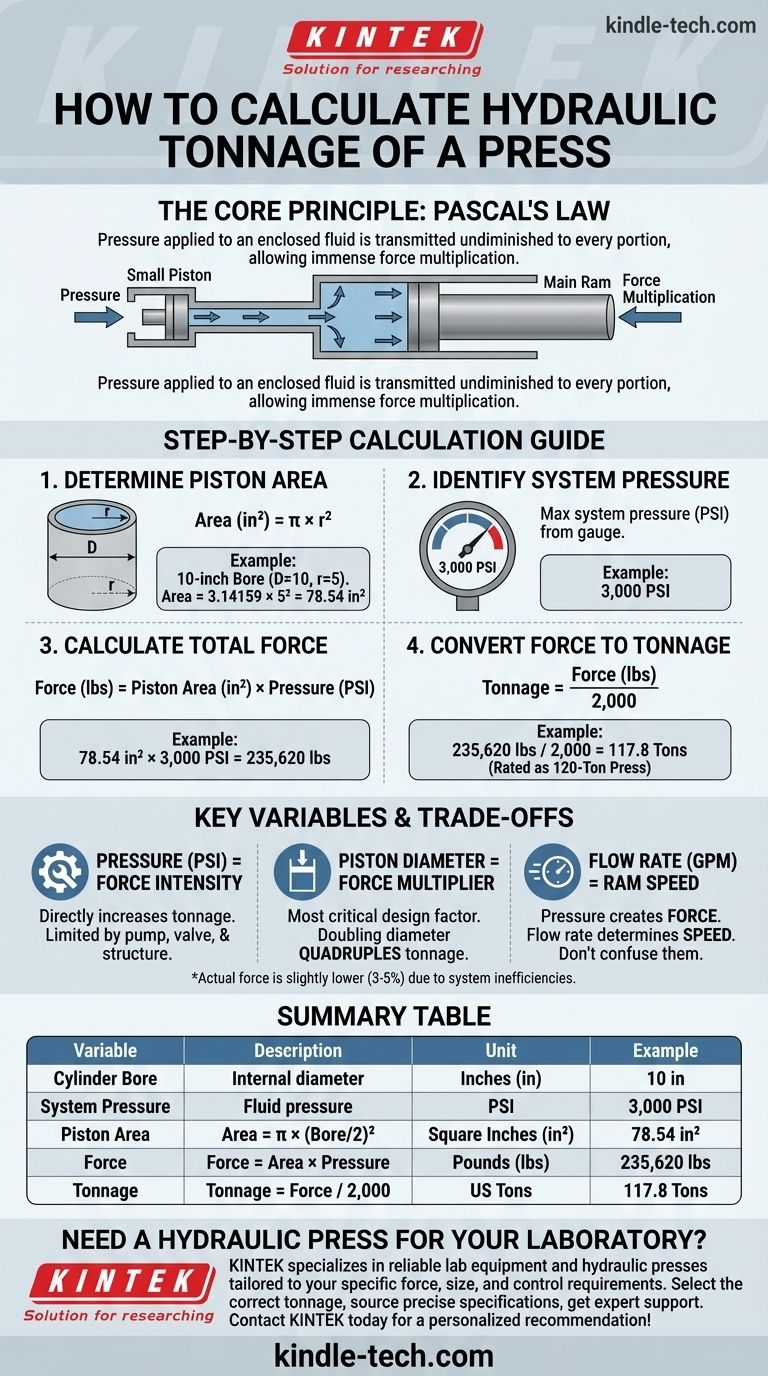

Calculating the tonnage of a hydraulic press is a direct application of fundamental physics. The calculation multiplies the hydraulic pressure exerted by the fluid by the total surface area of the piston inside the main cylinder. This result gives you the total force in pounds, which is then converted into tons.

The core principle is this: A press's force isn't determined by the size of its motor or pump, but by the combination of its maximum system pressure (PSI) and the piston's surface area. Grasping this simple relationship is the key to correctly specifying, operating, and troubleshooting any hydraulic press.

The Core Principle: Pascal's Law Explained

The entire operation of a hydraulic press is governed by a principle discovered in the 17th century. Understanding it moves you from simply using a formula to truly understanding the machine.

What is Pascal's Law?

Pascal's Law states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, pressure applied anywhere in the system is felt equally everywhere else in the system.

How This Creates Force Multiplication

This principle allows for immense force multiplication. A small amount of pressure applied to a small piston (in the pump) is transmitted to a much larger piston (the main ram). Because the main ram has a much larger surface area, the resulting force is magnified proportionally.

Step-by-Step Calculation Guide

Follow these steps to find the theoretical maximum tonnage of your press. You will need the cylinder's bore (internal diameter) and the system's maximum pressure, typically read from a gauge.

Step 1: Determine the Piston Area

First, calculate the surface area of the main piston on which the hydraulic fluid pushes. The formula for the area of a circle is πr².

- Measure the cylinder's internal diameter (bore) in inches.

- Divide the diameter by 2 to get the radius (r).

- Calculate the Area: Area (in²) = 3.14159 x (radius)²

For example, a press with a 10-inch diameter cylinder has a radius of 5 inches. The area would be 3.14159 x (5²) = 78.54 square inches.

Step 2: Identify the System Pressure

Find the maximum system pressure, which is measured in Pounds per Square Inch (PSI). This value is typically found on the press's pressure gauge and is set by a pressure relief valve.

Let's assume the gauge on our example press reads 3,000 PSI.

Step 3: Calculate the Total Force

Now, multiply the piston area by the system pressure to find the total force output in pounds.

- Force (lbs) = Piston Area (in²) x Pressure (PSI)

- In our example: 78.54 in² x 3,000 PSI = 235,620 pounds of force.

Step 4: Convert Force to Tonnage

The final step is to convert the force from pounds into US tons. The standard conversion is 1 ton = 2,000 pounds.

- Tonnage = Force (lbs) / 2,000

- In our example: 235,620 lbs / 2,000 = 117.8 tons.

This press would be rated as a 120-ton press.

Understanding the Trade-offs and Key Variables

The calculation is simple, but the interplay between the variables has significant consequences for performance and safety.

The Role of Pressure (PSI)

Pressure is the "intensity" of the force. Increasing the pressure setting directly increases the final tonnage. However, it is limited by the pump's capability, the pressure relief valve setting, and the structural integrity of the cylinder, frame, and hoses.

The Impact of Piston Diameter

The piston's area is the "force multiplier." Even a small increase in diameter creates a large increase in area and, therefore, force. Doubling a piston's diameter quadruples its surface area and tonnage output. This is the most critical design factor of a press.

The Difference Between Force and Speed

It is a common mistake to confuse pressure with speed. Pressure (PSI) creates force, while the fluid flow rate (Gallons Per Minute, or GPM) from the pump determines the ram's travel speed. You can have a very high-tonnage press that moves very slowly.

System Inefficiencies

The formula provides the theoretical maximum force. The actual force delivered at the workpiece will be slightly lower (typically 3-5%) due to friction from cylinder seals and fluid moving through the system. This is a minor factor for most applications but is important to acknowledge.

Making the Right Choice for Your Goal

Use this understanding to make informed decisions based on your specific objective.

- If your primary focus is buying a new press: Determine the tonnage you need for your job first, then evaluate presses based on their combination of cylinder bore and pressure rating to meet that need.

- If your primary focus is troubleshooting a press: Use this calculation with the current gauge reading to confirm if the press is delivering the expected force or if there might be a problem with the gauge or hydraulic system.

- If your primary focus is designing a process or tooling: Always use the press's maximum theoretical tonnage for your safety calculations to ensure your dies and safety equipment can withstand a worst-case scenario.

By mastering this fundamental calculation, you gain direct control over the performance, safety, and application of your hydraulic equipment.

Summary Table:

| Variable | Description | Unit | Example |

|---|---|---|---|

| Cylinder Bore Diameter | Internal diameter of the main piston | Inches (in) | 10 in |

| System Pressure | Hydraulic fluid pressure | PSI | 3,000 PSI |

| Piston Area | Area = π × (Bore/2)² | Square Inches (in²) | 78.54 in² |

| Force | Force = Area × Pressure | Pounds (lbs) | 235,620 lbs |

| Tonnage | Tonnage = Force / 2,000 | US Tons | 117.8 Tons |

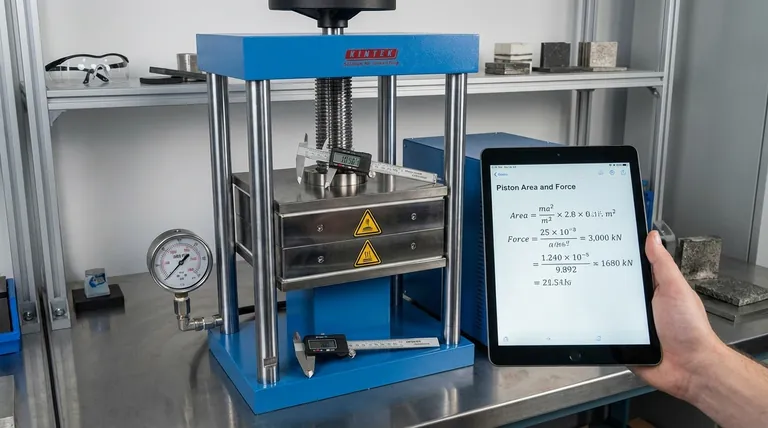

Need a Hydraulic Press for Your Laboratory?

Understanding tonnage is crucial for selecting the right press for your material testing, sample preparation, or R&D work. KINTEK specializes in providing reliable lab equipment, including hydraulic presses tailored to your specific force, size, and control requirements.

We can help you:

- Select the correct tonnage for your application to ensure safety and efficiency.

- Source presses with the precise specifications your lab needs.

- Get expert support to optimize your processes.

Contact KINTEK today to discuss your lab's hydraulic press needs and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What size are extrusion pellets? Mastering Pellet Geometry for Optimal Extrusion Performance

- How does the high pressure provided by a laboratory hydraulic press impact the formation of solid-state battery cells?

- What is the capacities of a hydraulic press? From 1-Ton Lab Presses to 10,000+ Ton Industrial Giants

- Why are high-precision laboratory hydraulic presses necessary? Mastering Ceramic Membrane Green Body Manufacturing

- What scientific principle governs the operation of a hydraulic press? Master Pascal’s Law for Force Multiplication

- How does a laboratory hydraulic press improve regenerated leather quality? Enhance Strength and Density

- Why is a hydraulic press required for the lamination process? Essential Steps for Solid-State Battery Assembly

- What industry uses hydraulic press? Powering Manufacturing from Automotive to Aerospace