To calculate the power consumption of an induction furnace, you multiply your desired hourly production rate by the specific energy required to melt your material. For example, melting 1000 kg (1 metric ton) of iron typically requires between 550 and 650 kWh of energy. The result gives you the required power supply in kilowatts (kW) needed to meet that production goal.

The core challenge is not the calculation itself, but accurately determining the "specific energy consumption" value for your unique material, target temperature, and operational efficiency. This single variable is the key to a realistic power estimate.

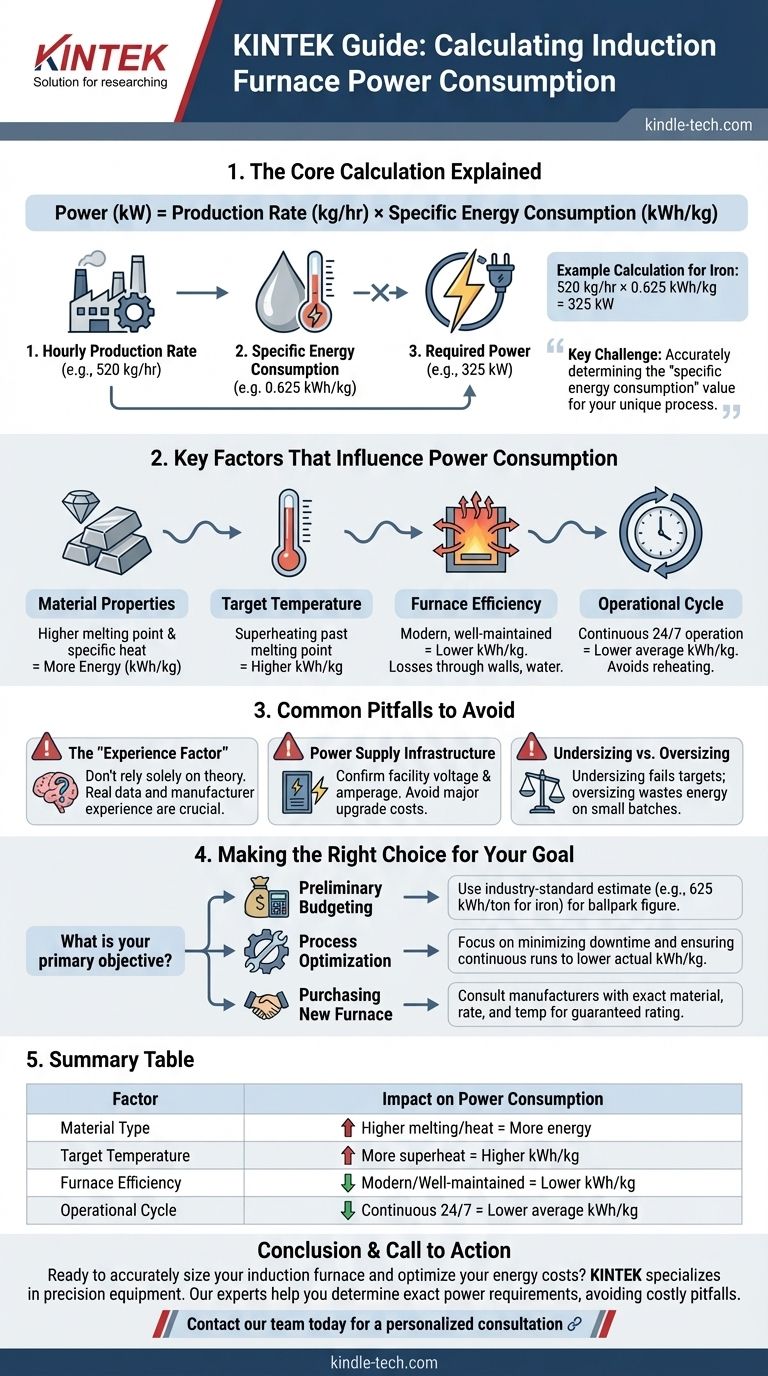

The Core Calculation Explained

The formula for determining the required furnace power is straightforward. It involves understanding your production needs and the energy intensity of your specific process.

Step 1: Determine Hourly Production Rate

First, define how much material you need to process per hour. This is measured in kilograms per hour (kg/hr) or tons per hour.

This rate is the primary driver of your power requirement; melting more material in the same amount of time will always demand more power.

Step 2: Identify Specific Energy Consumption

This is the most critical and variable part of the calculation. It represents the kilowatt-hours (kWh) needed to melt one kilogram (or ton) of a specific metal to a specific temperature.

For general-purpose iron melting, a common estimate is 625 kWh per 1000 kg (or 0.625 kWh/kg). However, this number changes based on the factors discussed below.

Step 3: Calculate Required Power

Finally, multiply your production rate by the specific energy consumption to find the necessary power supply in kilowatts (kW).

Formula: Power (kW) = Production (kg/hr) × Specific Energy Consumption (kWh/kg)

For example, to produce 520 kg of molten iron per hour using our estimate: 520 kg/hr × 0.625 kWh/kg = 325 kW. Your facility would need a power supply capable of delivering at least 325 kW continuously.

Key Factors That Influence Power Consumption

A simple calculation provides a baseline, but in the real world, several factors significantly alter the specific energy consumption value. Understanding these is essential for an accurate assessment.

Material Properties

Different materials have unique thermal properties. A metal with a higher melting point or a higher specific heat capacity will require more energy (a higher kWh/kg value) to melt.

Target Temperature

The final temperature of the molten metal, or "superheat," directly impacts energy use. Heating metal 100 degrees past its melting point requires significantly more power than just reaching the melting point.

Furnace Efficiency

Not all electrical energy drawn by the furnace converts into useful heat in the metal. Energy is lost through the furnace walls, cooling water circuits, and radiation. A modern, well-maintained furnace is more efficient and will have a lower kWh/kg value.

Operational Cycle

Continuous operation is far more energy-efficient. A furnace that runs 24/7 avoids the massive energy loss that occurs when it cools down between shifts. Stop-start operations always increase the average energy consumption per kilogram.

Common Pitfalls to Avoid

Relying solely on a theoretical calculation without considering practical constraints can lead to costly mistakes.

The "Experience Factor"

Manufacturers and experienced foundries develop their energy estimates over years of operation. These figures, based on real-world data, are often more reliable than a simple physics calculation because they inherently account for inefficiencies and process specifics.

Power Supply and Infrastructure

A furnace is a significant electrical load. You must confirm your facility has the required voltage and amperage to support the machine. Underestimating this can lead to major infrastructure upgrade costs.

Undersizing vs. Oversizing

Selecting a furnace with insufficient power (undersizing) means you will never meet your production targets. Choosing one that is too powerful (oversizing) will run inefficiently for smaller batches, wasting energy and increasing your cost per kilogram.

Making the Right Choice for Your Goal

Use the calculation as a tool, but frame it with your primary objective to arrive at the best decision.

- If your primary focus is preliminary budgeting: Use the simple formula with an industry-standard energy value (e.g., 625 kWh/1000 kg for iron) to get a reliable ballpark estimate for initial planning.

- If your primary focus is process optimization: Focus less on the furnace's nameplate power and more on operational factors like minimizing downtime and ensuring continuous runs to lower your actual kWh/kg consumption.

- If your primary focus is purchasing a new furnace: Consult directly with multiple manufacturers, providing them with your exact material, production rate, and target temperature to get an accurate and guaranteed power rating.

Ultimately, understanding the factors that drive power consumption empowers you to select the right equipment and operate it efficiently.

Summary Table:

| Factor | Impact on Power Consumption |

|---|---|

| Material Type | Higher melting point/specific heat = More energy (kWh/kg) |

| Target Temperature | More superheat (past melting point) = Higher kWh/kg |

| Furnace Efficiency | Modern, well-maintained furnaces = Lower kWh/kg |

| Operational Cycle | Continuous 24/7 operation = Lower average kWh/kg |

Ready to accurately size your induction furnace and optimize your energy costs?

KINTEK specializes in precision lab and industrial equipment, including induction furnaces. Our experts can help you determine the exact power requirements for your specific material and production goals, ensuring you avoid the costly pitfalls of undersizing or oversizing.

Contact our team today for a personalized consultation and let us help you achieve efficient and reliable melting performance.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting