To clean a muffle furnace, first ensure it is completely cool and disconnected from power, then use a soft brush and a vacuum cleaner to remove any loose ash or residue from the chamber. For any remaining dirt, you can wipe the interior with a slightly damp cloth, making certain the chamber is completely dry before its next use.

While the physical act of cleaning a muffle furnace is straightforward, the true goal is ensuring its long-term reliability and safety. This is achieved not just by cleaning, but by adopting proper operational procedures that prevent contamination and damage in the first place.

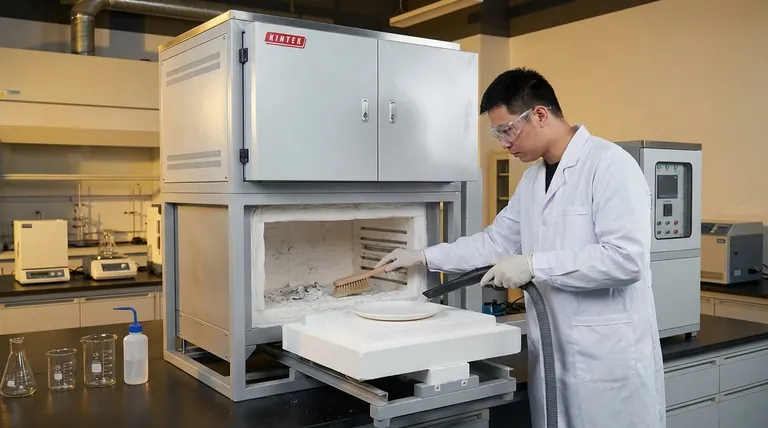

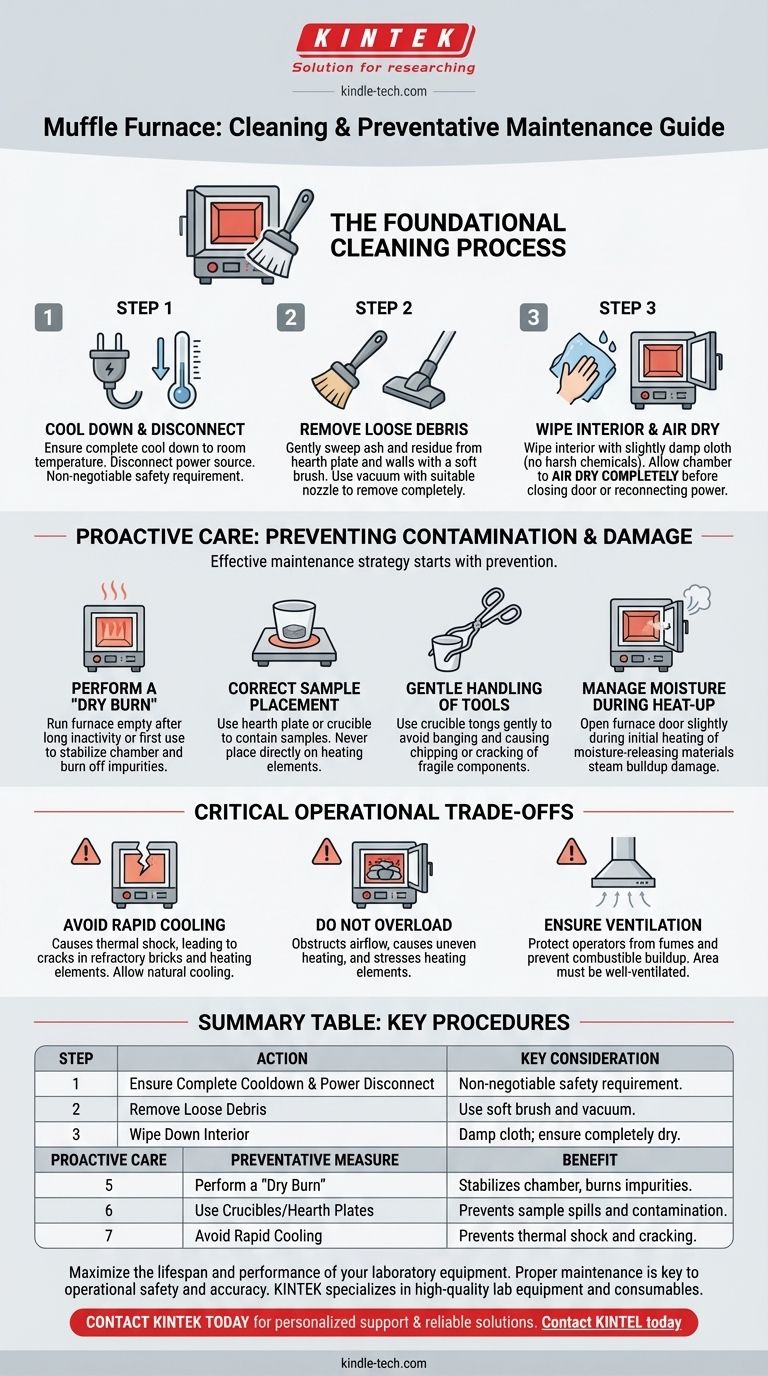

The Foundational Cleaning Process

A clean furnace ensures accurate heating and prolongs the life of the internal components. Always perform this process when the unit is cold and unplugged.

Step 1: Ensure Complete Cooldown and Power Disconnect

Before any cleaning, the absolute first step is to verify the furnace has returned to room temperature and is disconnected from its power source. This is a non-negotiable safety requirement.

Step 2: Remove Loose Debris

Use a soft-bristled brush to gently sweep any ash, residue, or particles from the hearth plate and chamber walls.

A vacuum cleaner with a suitable nozzle is highly effective for removing this dislodged debris completely from the chamber.

Step 3: Wipe Down the Interior

For any stubborn dirt, lightly dampen a clean cloth with water and wipe the interior surfaces. Avoid using harsh chemicals or excessive water.

It is critical that the furnace chamber is allowed to air dry completely before you close the door or reconnect power. Operating the furnace with residual moisture can cause thermal shock and crack the refractory insulation.

Proactive Care: Preventing Contamination and Damage

The most effective maintenance strategy is prevention. Proper daily operation will drastically reduce the need for cleaning and will protect the furnace from premature failure.

The Importance of a "Dry Burn"

After the first use or a long period of inactivity, run the furnace empty for a period. This "dry burn" helps stabilize the chamber and burn off any accumulated moisture or minor impurities.

Correct Sample Placement

Never place samples directly on the heating elements or the furnace floor. Use a hearth plate or appropriate crucible to contain your sample and prevent spills or reactions that could damage the insulation.

Gentle Handling of Tools

When placing or retrieving samples, use crucible tongs carefully. Banging tongs against the furnace door, walls, or heating elements can easily cause chipping and cracking of these fragile components.

Managing Moisture During Heat-up

When heating materials that may release moisture, open the furnace door slightly (leaving a small gap) during the initial heating phase. This allows moisture to escape, preventing steam buildup that can damage the refractory lining.

Understanding Critical Operational Trade-offs

Improper operation is the leading cause of furnace damage. Understanding the consequences of common shortcuts is key to maintaining your equipment.

Rapid Cooling vs. Furnace Integrity

Never attempt to cool the furnace rapidly by opening the door wide or introducing cool air. The resulting thermal shock is a primary cause of cracks in the internal refractory bricks and can damage heating elements. Always allow the furnace to cool down naturally with the door closed.

Overloading vs. Heating Performance

Overloading the chamber obstructs airflow and leads to uneven heating and inaccurate temperatures. It also puts unnecessary stress on the heating elements, shortening their lifespan.

Ventilation vs. Operator Safety

A working muffle furnace generates significant heat and can release fumes from the materials being processed. Ensure the area is well-ventilated to protect operators and to prevent the buildup of combustible materials or fumes around the unit.

Key Procedures for Furnace Longevity

Your approach to furnace care should align with the goals of safety, accuracy, and durability.

- If your primary focus is routine cleaning: After every few uses, perform the cool-down, brush, vacuum, and wipe-down procedure to keep the chamber free of residue.

- If your primary focus is preventing damage: Always avoid thermal shock by cooling naturally, use tongs gently, and manage moisture by cracking the door during initial heat-up.

- If your primary focus is ensuring safety: Always disconnect power before maintenance, ensure proper ventilation, and never place flammable materials inside or near the furnace.

Consistent and correct operational habits are the most effective way to ensure your muffle furnace remains a reliable and safe tool for years to come.

Summary Table:

| Step | Action | Key Consideration |

|---|---|---|

| 1 | Ensure Complete Cooldown & Power Disconnect | Non-negotiable safety requirement. |

| 2 | Remove Loose Debris | Use a soft brush and vacuum. |

| 3 | Wipe Down Interior | Use a slightly damp cloth; ensure chamber is completely dry before use. |

| Proactive Care | Preventative Measure | Benefit |

| - | Perform a "Dry Burn" | Stabilizes chamber and burns off impurities. |

| - | Use Crucibles/Hearth Plates | Prevents sample spills and contamination. |

| - | Avoid Rapid Cooling | Prevents thermal shock and cracking. |

Maximize the lifespan and performance of your laboratory equipment. Proper maintenance is key to operational safety and accuracy. KINTEK specializes in high-quality lab equipment and consumables, including muffle furnaces and the necessary accessories for their care. Let our experts help you ensure your lab runs efficiently and safely.

Contact KINTEL today for personalized support and to explore our range of reliable laboratory solutions.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Does ceramic break with heat? The Real Culprit is Thermal Shock

- What is the use of muffle furnace in soil? Analyze Soil Composition with High-Temperature Precision

- What are furnaces usually made of? A Guide to Materials for Extreme Temperatures

- What are the four steps to the heat treating process? Master the 3 Core Stages for Superior Results

- What does a lab muffle furnace do? Achieve Pure, Contamination-Free Heating for Your Lab