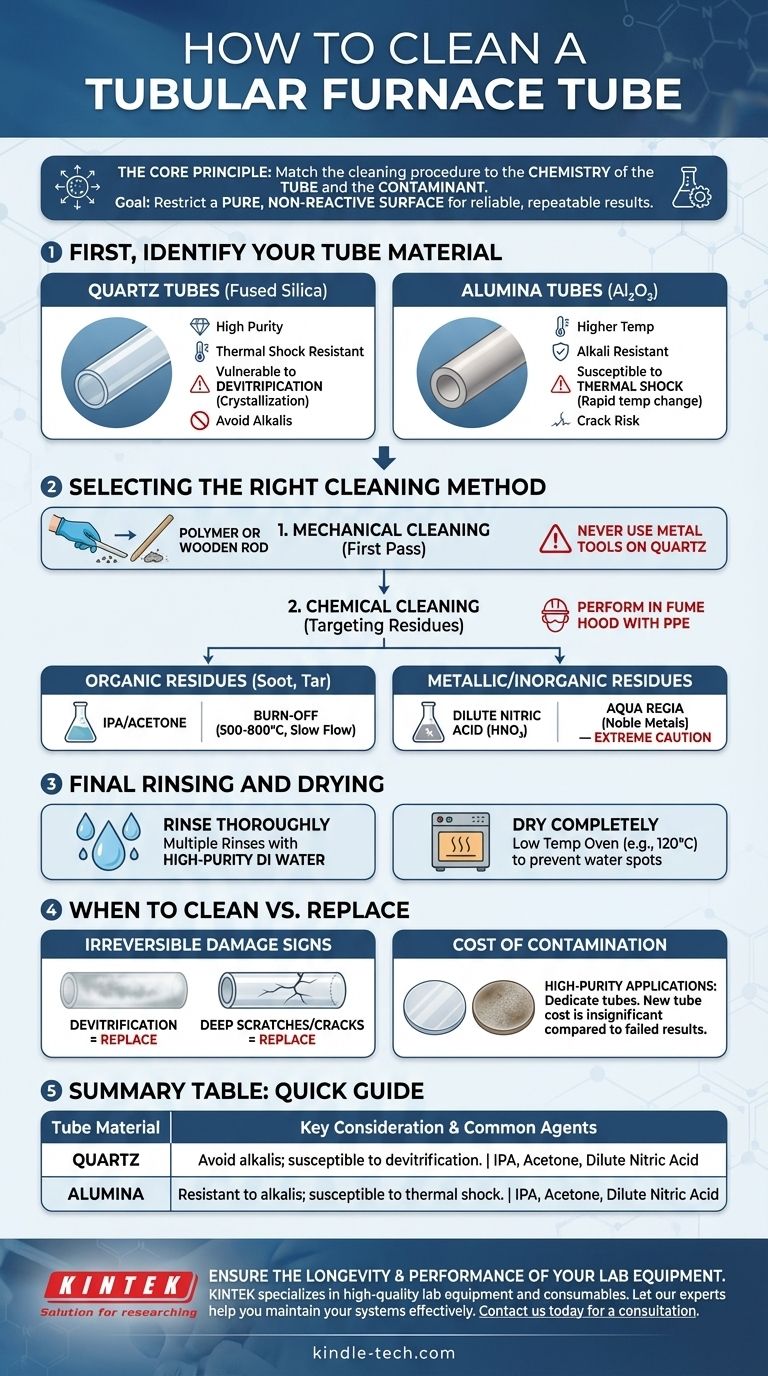

The method for cleaning a tubular furnace tube depends entirely on the tube's material—most commonly quartz or alumina—and the specific type of residue left from your process. There is no single universal cleaning agent; using the wrong method can permanently damage the tube or introduce new contaminants.

The core principle is to match the cleaning procedure to the chemistry of both the tube and the contaminant. Your goal is not just to make the tube look clean, but to restore a pure, non-reactive surface essential for reliable and repeatable results in high-temperature environments.

First, Identify Your Tube Material

The material of your process tube is the single most important factor in determining a safe cleaning procedure. Using a method incompatible with your tube will lead to failure.

Quartz Tubes

Quartz (fused silica) is extremely common due to its high purity and excellent thermal shock resistance. However, it is a glass and has specific vulnerabilities.

It is susceptible to devitrification—a process where it crystallizes and becomes opaque and brittle—especially when heated in the presence of alkali metals or other contaminants.

Alumina Tubes

Alumina (Al₂O₃) is a dense, robust ceramic capable of reaching higher temperatures than quartz. It is generally more chemically resistant to alkalis.

However, it is more susceptible to thermal shock than quartz. Rapid temperature changes can cause it to crack.

Selecting the Right Cleaning Method

Always start with the least aggressive method possible and escalate only as needed. The reference to a "drainage tube" is for a residential HVAC system and is not applicable here.

Mechanical Cleaning (The First Pass)

For loose debris or thick deposits, a gentle mechanical approach is the first step.

Use a long polymer or wooden rod to carefully dislodge material. Never use a metal tool inside a quartz tube, as it will scratch the surface, creating nucleation sites for devitrification and eventual failure.

Chemical Cleaning (Targeting Residues)

This step requires careful selection based on the contaminant. Always perform chemical cleaning in a well-ventilated fume hood with appropriate Personal Protective Equipment (PPE).

- For Organic Residues (Soot, Tar): First, try common lab solvents like isopropyl alcohol (IPA) or acetone. If that fails, a high-temperature "burn-off" or anneal (e.g., 500-800°C) with a slow flow of air or oxygen can effectively oxidize the carbon.

- For Metallic/Inorganic Residues: Dilute acids are often required. A 5-10% solution of nitric acid (HNO₃) is a good starting point for many common metals. For noble metals like gold, aqua regia (a mix of nitric and hydrochloric acid) may be necessary, but this is extremely corrosive and requires advanced safety protocols.

Final Rinsing and Drying

After any chemical treatment, the tube must be thoroughly rinsed to remove all traces of the cleaning agent.

Rinse multiple times with high-purity deionized (DI) water. An improperly rinsed tube will introduce new contaminants in your next process.

Finally, dry the tube completely in a drying oven at a low temperature (e.g., 120°C) to prevent water spots and ensure no moisture remains before it is returned to high-temperature service.

Understanding the Trade-offs: When to Clean vs. Replace

Cleaning is not always the best option. Aggressive cleaning can damage a tube, and the risk of cross-contamination can compromise sensitive processes.

Signs of Irreversible Damage

Be aware of signs that a tube is nearing the end of its life.

For quartz, look for hazy, opaque white spots—this is devitrification. These areas are structurally weak and will eventually lead to cracking. For any tube, deep scratches, pits, or visible cracks are clear indicators that it must be replaced.

The Cost of Contamination

For high-purity applications like semiconductor research, the risk of trace contaminants from a previously used tube is often too high.

In these scenarios, the cost of a new, dedicated process tube is insignificant compared to the cost of failed experiments or tainted results.

Making the Right Choice for Your Process

Follow this checklist to ensure you are using a safe and effective procedure for your specific situation.

- If you are dealing with organic films or soot: Start with a solvent wash (IPA, acetone) followed by a high-temperature air anneal if necessary.

- If you are removing common metallic deposits: Use a dilute nitric acid solution in a fume hood, ensuring it is compatible with your tube material.

- If your quartz tube looks hazy or cloudy: This is likely devitrification. Aggressive cleaning will not reverse it, and you should plan to replace the tube soon.

- If you work in a high-purity field: It is often better practice to dedicate specific tubes to specific materials or processes rather than risk cross-contamination.

Proper tube maintenance is the foundation of repeatable and reliable high-temperature processing.

Summary Table:

| Tube Material | Key Consideration | Common Cleaning Agents |

|---|---|---|

| Quartz | Avoid alkalis; susceptible to devitrification | IPA, Acetone, Dilute Nitric Acid (for metals) |

| Alumina | Resistant to alkalis; susceptible to thermal shock | IPA, Acetone, Dilute Nitric Acid (for metals) |

Ensure the longevity and performance of your lab equipment. Proper maintenance is critical for reliable results. KINTEK specializes in high-quality lab equipment and consumables, including furnace tubes and cleaning accessories, serving all your laboratory needs.

Let our experts help you maintain your systems effectively. Contact us today for a consultation to discuss your specific requirements and ensure your processes run smoothly.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What technical conditions does a tube furnace provide for Cr-Mg alloy coatings? Master Precision 1050°C Diffusion

- Why are stainless steel 1.4404 or glass preferred for continuous reactors in cyclooctene epoxidation? Expert Insights

- Why is a tube furnace with Argon needed for CCN synthesis? Achieve High-Crystallinity Nanorods with Inert Protection

- What are the limitations of a vacuum tube furnace for applications at 1450°C? Key Constraints for High-Temp Processes

- What are the primary functions of high-temperature tube furnaces? Master Iron Oxide Nanoparticle Synthesis

- What are the advantages of using a Multi-zone Tube Furnace? Enhanced Thermal Uniformity for Diffusion Research

- How do high-temperature tube furnaces maintain accuracy in sulfur oxide atmospheres? Ensure Precise Gas Control

- What is the difference between a tube furnace and a box furnace? Choose the Right Heat Treatment Process