The short answer is that you cool a muffle furnace by turning off the heating elements and allowing it to cool down slowly and naturally. For most applications, this involves simply leaving the furnace door closed and letting the temperature fall over several hours. This controlled, passive process is essential to prevent damage to the furnace and the material inside.

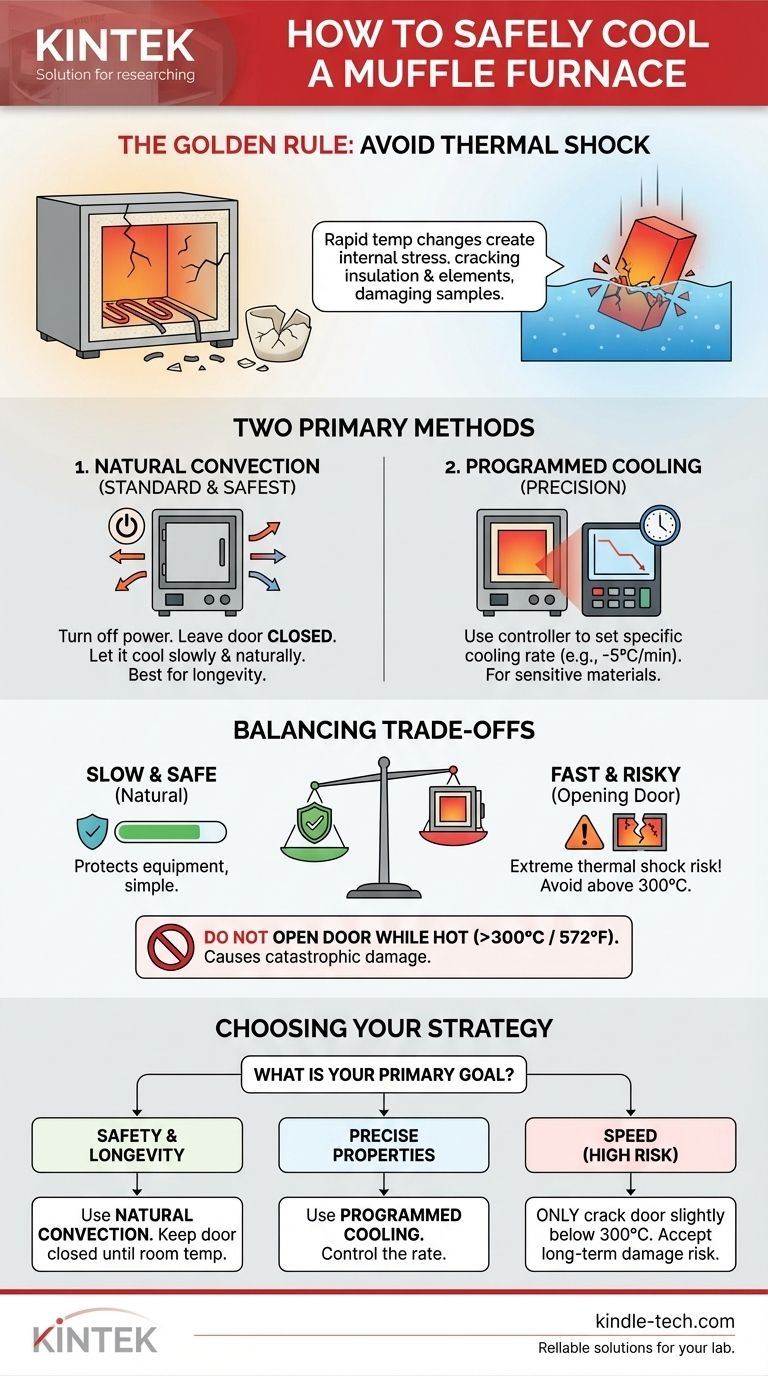

The single most important principle in cooling a muffle furnace is to avoid thermal shock. Abrupt temperature changes create internal stresses that can crack the furnace's delicate insulation and heating elements, drastically reducing its lifespan and compromising its performance.

The Core Principle: Avoiding Thermal Shock

What is Thermal Shock?

Thermal shock occurs when a material experiences a rapid change in temperature, causing different parts of it to expand or contract at different rates. This differential creates immense internal stress.

Imagine plunging a hot ceramic dish into cold water—it shatters. The same principle applies to your furnace's internal components.

The Impact on Furnace Components

Muffle furnaces are lined with refractory materials, a type of ceramic insulation designed to withstand extreme heat. While durable at stable high temperatures, these materials are often brittle and highly susceptible to thermal shock.

Rapid cooling will cause this lining to crack, flake, and degrade over time. It can also damage the metallic heating elements, leading to premature failure and costly repairs.

The Impact on Your Sample

The material you are heating (your workpiece or sample) is also at risk. Whether you are annealing metal, ashing a sample, or growing crystals, a sudden drop in temperature can induce stress, cause cracking, or alter the material's final properties in an undesirable way.

Methods for Cooling a Muffle Furnace

You have two primary, safe methods for cooling, both of which are managed by the furnace's temperature controller.

Method 1: Natural Convection Cooling (The Standard)

This is the safest, most common, and highly recommended method for general use. The process is simple: the temperature controller shuts off power to the heating elements.

The furnace, with its door securely closed, then dissipates heat naturally into the surrounding environment. The high-quality insulation that keeps the heat in also ensures that it escapes slowly, resulting in a gradual and safe cooling curve.

Method 2: Programmed Cooling (For Precision)

For sensitive applications like metallurgy or crystal growth, you may need to control the rate of cooling precisely. Advanced temperature controllers allow you to program a "cooling ramp."

Instead of just cutting power, the controller actively reduces the temperature setpoint in controlled steps over a defined period (e.g., cool from 1000°C to 500°C at a rate of 5°C per minute). This offers maximum control over a material's final properties.

Understanding the Key Trade-offs

Choosing a cooling method involves balancing speed against the safety and integrity of your equipment and sample.

Speed vs. Safety

Natural convection is slow but guarantees the safety of the furnace. Any attempt to speed up cooling, such as opening the door, dramatically increases the risk of thermal shock.

Opening the door on a hot furnace (e.g., above 300°C / 572°F) can cause immediate, catastrophic damage to the refractory lining and elements. A rush of cool, dense air creates a severe thermal gradient that the materials cannot withstand.

Control vs. Simplicity

Natural cooling is simple and requires no special setup. The cooling rate is determined by the furnace's design and the ambient temperature.

Programmed cooling provides absolute control but requires a controller with programming capabilities and a proper understanding of the material's thermal properties.

Furnace Lifespan

Aggressive cooling is the single fastest way to destroy a muffle furnace. Each instance of thermal shock contributes to cumulative damage, shortening the lifespan of the insulation and heating elements. A patient, controlled approach to cooling maximizes your investment and ensures reliable performance.

Choosing the Right Cooling Strategy

Base your cooling method on your primary goal and always prioritize the health of the equipment.

- If your primary focus is safety and furnace longevity: Always use natural convection cooling by turning off the heat and leaving the door closed until the furnace is near room temperature.

- If you are processing sensitive materials requiring specific properties: Use a programmed cooling cycle to ensure a repeatable and precise cooling rate.

- If you absolutely need to access your sample faster: Only consider opening the door a small crack once the temperature has fallen below 200-300°C (392-572°F), and only if you are willing to accept the increased risk of long-term damage.

Ultimately, treating the cooling process with the same care as the heating process is fundamental to achieving consistent results and protecting your equipment.

Summary Table:

| Method | Process | Key Benefit | Ideal Use Case |

|---|---|---|---|

| Natural Convection | Turn off heat, keep door closed, let cool naturally. | Safest for furnace longevity. | General applications (ashing, annealing). |

| Programmed Cooling | Use controller to set a precise cooling rate. | Maximum control over material properties. | Sensitive processes (metallurgy, crystal growth). |

Protect your investment and ensure precise results. Proper furnace operation is critical for lab efficiency and data integrity. KINTEK specializes in high-quality lab equipment, including reliable muffle furnaces with advanced controllers. Let our experts help you choose the right furnace for your specific cooling and heating needs.

Contact KINTEK today for a consultation and enhance your laboratory's capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you perform calcination? Master Precise Thermal Treatment for Your Materials

- What temperature is required for calcination? Master Material-Specific Thermal Decomposition

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- What are the uses of muffle furnace in pharmaceutical industry? Essential for Drug Purity & Safety

- Can calcination be done in a muffle furnace? Yes, for precise air-atmosphere heating.