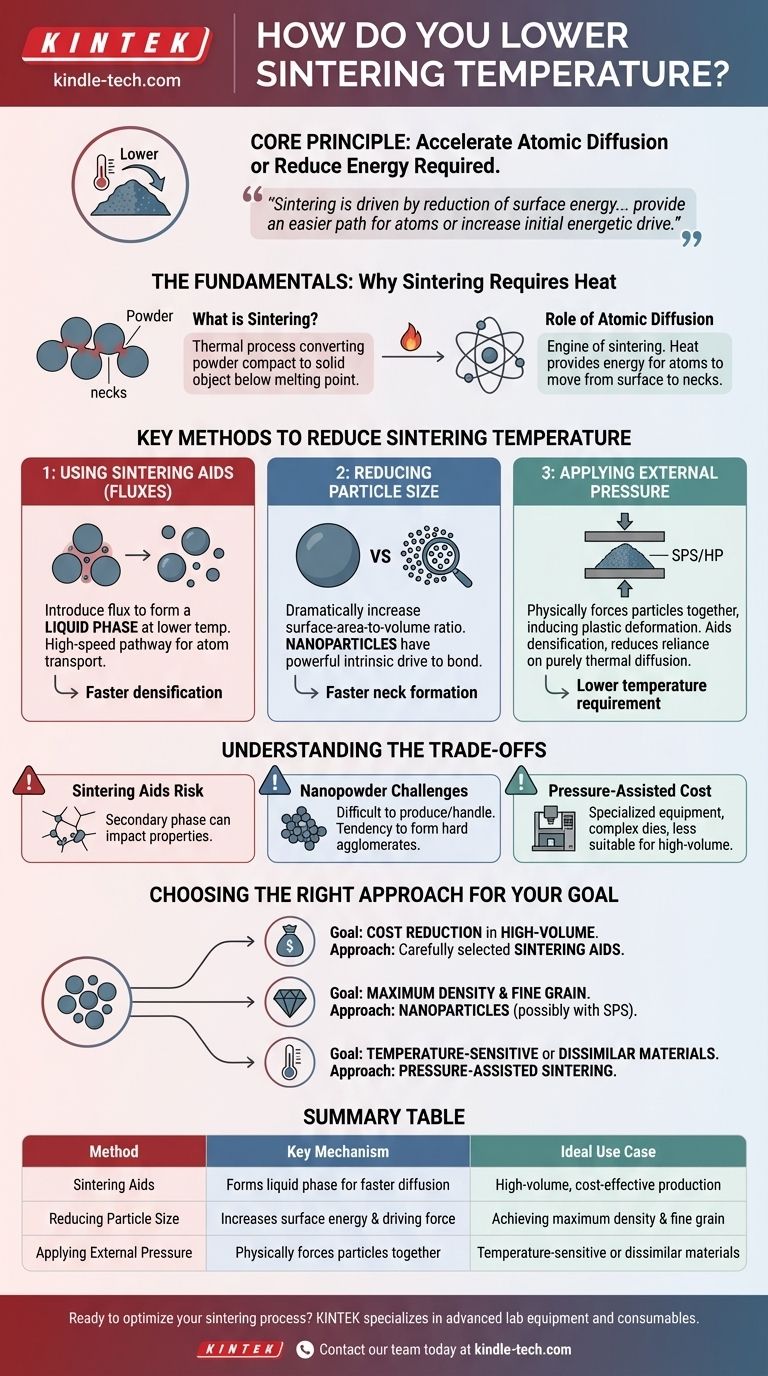

To lower the sintering temperature, you must find ways to accelerate the atomic diffusion process that bonds particles together, or reduce the energy required to initiate it. The most common methods involve using chemical additives known as sintering aids (fluxes), reducing the initial particle size of your powder (especially to the nanoscale), or applying external pressure during the heating cycle.

The core principle of lowering sintering temperature is not about using a better furnace, but about altering the material system itself. Sintering is driven by the reduction of surface energy, and you can achieve this at a lower temperature by either providing an easier path for atoms to move or by increasing the initial energetic drive to sinter.

The Fundamentals: Why Sintering Requires Heat

What is Sintering?

Sintering is a thermal process that converts a powder compact into a dense, solid object. It is crucial to understand that this happens below the material's melting point.

Instead of melting, particles fuse together where they touch. These points of contact, called "necks," grow over time, eliminating the pore spaces between the particles and causing the object to densify and shrink.

The Role of Atomic Diffusion

The engine of sintering is atomic diffusion. Heat provides the energy for atoms to move from the surface of the particles to the growing necks.

Without sufficient thermal energy, atoms are locked in place, and the densification process will not occur. The sintering temperature is the point at which this atomic movement becomes significant enough to achieve the desired density in a reasonable amount of time.

Key Methods to Reduce Sintering Temperature

Method 1: Using Sintering Aids (Fluxes)

The most common industrial method is to introduce sintering aids, also known as fluxes. These are small amounts of a secondary material mixed in with the main powder.

These aids are chosen because they can form a liquid phase at a temperature well below the melting point of the primary material. This liquid coats the particles and acts as a high-speed pathway for atoms to dissolve, travel, and reprecipitate at the necks.

Because transport through a liquid is much faster than through a solid, the overall temperature needed to achieve densification is significantly reduced.

Method 2: Reducing Particle Size

The driving force for sintering is the excess energy associated with the high surface area of a powder. By reducing the particle size, you dramatically increase the surface-area-to-volume ratio.

Nanoparticles are the extreme example of this principle. Their immense surface energy creates a powerful intrinsic drive to bond together, lowering the activation energy needed for diffusion to begin.

Furthermore, smaller particles mean shorter distances for atoms to travel to form necks, which also speeds up the process at any given temperature.

Method 3: Applying External Pressure

Methods like Hot Pressing (HP) or Spark Plasma Sintering (SPS) apply external mechanical pressure to the powder compact while it is being heated.

This pressure physically forces particles together, inducing plastic deformation at the contact points. This directly aids densification and reduces the reliance on purely thermal diffusion to close pores.

Because pressure provides an additional driving force for densification, the required temperature can often be lowered by hundreds of degrees.

Understanding the Trade-offs

The Risk of Secondary Phases

When using sintering aids, the additive material typically remains in the final object as a secondary phase, often at the grain boundaries. This can negatively impact the material's mechanical, thermal, or electrical properties.

Challenges with Nanopowders

While effective, nanopowders are difficult and expensive to produce and handle. They have a strong tendency to form hard clumps (agglomerates) due to their high surface energy.

If the nanopowder is not properly dispersed, these agglomerates act like large particles, negating the benefits of the small primary particle size.

The Cost and Complexity of Equipment

Pressure-assisted sintering requires specialized, expensive equipment compared to a conventional furnace. The complexity of the dies and the processing cycle makes it less suitable for high-volume, low-cost manufacturing.

Choosing the Right Approach for Your Goal

Selecting the correct method depends entirely on your end goal, balancing performance against cost and complexity.

- If your primary focus is cost reduction in high-volume production: Using carefully selected sintering aids is almost always the most economical and scalable approach.

- If your primary focus is achieving maximum density and the finest possible grain structure: Using nanoparticles, potentially combined with a pressure-assisted technique like SPS, is the most effective path.

- If your primary focus is sintering temperature-sensitive or dissimilar materials together: Pressure-assisted sintering provides the most control and allows for significant temperature reduction, preventing unwanted reactions or damage.

By understanding these fundamental levers, you can strategically control the sintering process to meet your specific material and economic targets.

Summary Table:

| Method | Key Mechanism | Ideal Use Case |

|---|---|---|

| Sintering Aids (Fluxes) | Forms a liquid phase for faster atomic diffusion | High-volume, cost-effective production |

| Reducing Particle Size | Increases surface energy and driving force | Achieving maximum density and fine grain structure |

| Applying External Pressure | Physically forces particles together | Temperature-sensitive or dissimilar materials |

Ready to optimize your sintering process and reduce operational costs? At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your material science challenges. Whether you're working with novel sintering aids or exploring pressure-assisted techniques, our experts can help you select the right tools to achieve superior results at lower temperatures. Contact our team today to discuss your specific needs and discover how KINTEK can enhance your laboratory's efficiency and innovation.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations