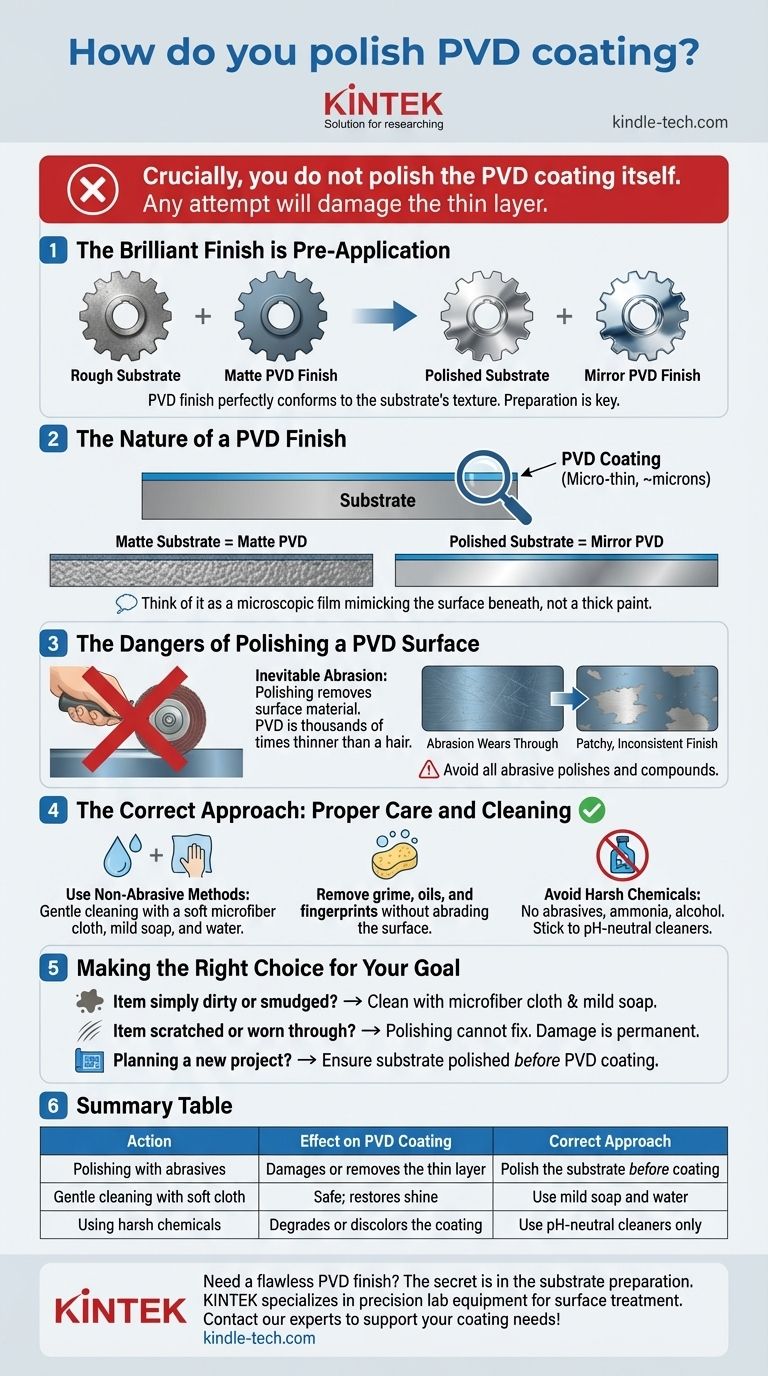

Crucially, you do not polish the PVD coating itself. Any attempt to use traditional abrasive polishes will almost certainly damage or completely remove this extremely thin, hard layer of deposited material. The brilliant, mirror-like finish associated with Physical Vapor Deposition (PVD) is achieved by meticulously polishing the base material, or substrate, before the coating is ever applied.

The core principle to understand is that a PVD coating is a micro-thin layer that perfectly conforms to the texture of the surface it covers. The final finish is determined entirely by the preparation of the underlying substrate, not by post-application polishing.

The Nature of a PVD Finish

A Deposited Layer, Not Solid Metal

Physical Vapor Deposition is a process where a solid material is vaporized in a vacuum and deposited, atom by atom, onto a substrate. This creates an incredibly thin—often just a few microns—but very hard and durable coating.

Think of it not as a thick layer of paint, but as a microscopic film that perfectly mimics the surface beneath it.

The Coating Reveals the Substrate

If the substrate material is bead-blasted to a matte texture before coating, the final PVD finish will be matte.

Conversely, if the substrate is polished to a flawless mirror shine, the PVD coating will also have a perfect mirror shine. The coating itself adds durability and color, but not texture or polish.

The Dangers of Polishing a PVD Surface

Inevitable Abrasion and Removal

All polishes, whether liquid compounds or polishing wheels, work through abrasion. They remove a microscopic amount of surface material to smooth out imperfections.

When applied to a PVD coating that is thousands of times thinner than a human hair, this abrasive action will quickly wear through the layer, exposing the substrate underneath.

Creating an Inconsistent Finish

Attempting to polish a PVD-coated item will result in a patchy, inconsistent appearance. You may burnish some areas while completely removing the coating in others, leading to a finish that is far worse than what you started with.

The Correct Approach: Proper Care and Cleaning

Use Non-Abrasive Methods

The proper way to maintain the luster of a PVD finish is through gentle cleaning. Use a soft microfiber cloth with mild soap and water.

This will remove fingerprints, oils, and grime without abrading the surface, restoring its original intended appearance.

Avoid Harsh Chemicals

Steer clear of any cleaning agents that contain abrasives, ammonia, alcohol, or other harsh chemicals. These can degrade or discolor the PVD coating over time. Sticking to pH-neutral cleaners is the safest method.

Making the Right Choice for Your Goal

- If your PVD item is simply dirty or smudged: Your goal is cleaning, not polishing. Use a microfiber cloth and mild, non-abrasive soap to restore its shine.

- If your PVD item is scratched or worn through: Polishing cannot fix this. The damage is permanent, and the only true solution is to have the item professionally stripped and recoated, which is often impractical.

- If you are planning a new project with a PVD finish: Ensure your manufacturer polishes the raw substrate to your desired level of sheen before the PVD coating process begins.

Understanding that the final finish lies beneath the coating is the key to preserving the beauty and durability of any PVD-coated item.

Summary Table:

| Action | Effect on PVD Coating | Correct Approach |

|---|---|---|

| Polishing with abrasives | Damages or removes the thin layer | Polish the substrate before coating |

| Gentle cleaning with soft cloth | Safe; restores shine | Use mild soap and water |

| Using harsh chemicals | Degrades or discolors the coating | Use pH-neutral cleaners only |

Need a flawless PVD finish for your components? The secret is in the substrate preparation. KINTEK specializes in precision lab equipment and consumables for surface treatment and coating processes. Our expertise ensures your substrates are perfectly prepared for durable, brilliant PVD coatings. Contact our experts today to discuss how we can support your laboratory's coating and finishing needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- What is the RF frequency for sputtering? Unlocking the Standard for Insulating Materials

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained

- How many types of sputtering are there? A Guide to DC, RF, and Advanced Techniques

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems