At its core, an induction heating system works by using a powerful, changing magnetic field to generate electrical currents directly within a conductive material. This process, known as electromagnetic induction, causes the material to heat itself from the inside out due to its own electrical resistance. This method is exceptionally fast and precise because it requires no direct contact or external flame.

The fundamental advantage of induction heating is that the workpiece becomes its own heating element. This internal heat generation is the key to its remarkable speed, efficiency, and control compared to conventional heating methods that transfer heat from an external source.

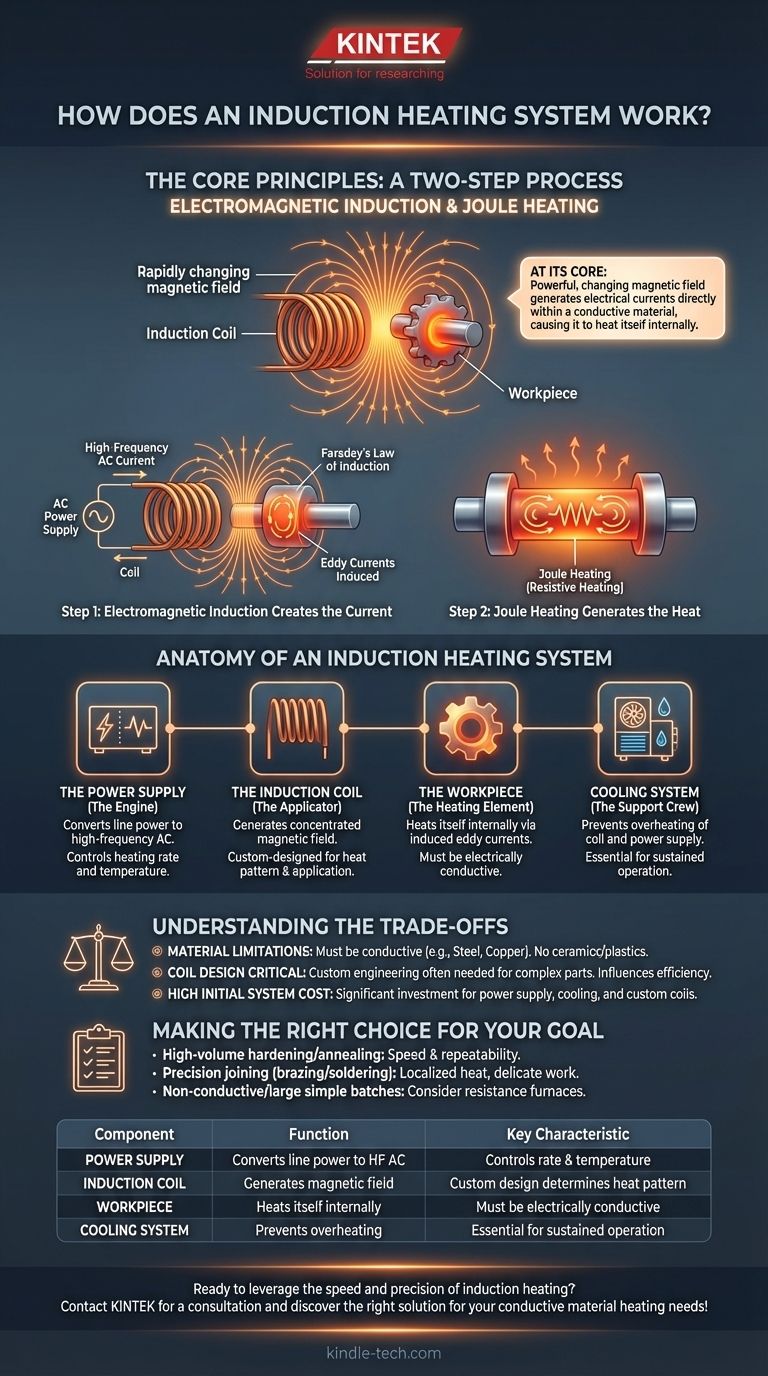

The Core Principles: A Two-Step Process

Induction heating is the practical application of two fundamental physics principles working in sequence: electromagnetic induction and Joule heating.

Step 1: Electromagnetic Induction Creates the Current

The process begins when a high-frequency alternating current (AC) is passed through a specially designed inductor, typically a copper coil. This flow of AC generates a concentrated and rapidly changing magnetic field around the coil.

When a conductive part (the workpiece) is placed inside this magnetic field, the field induces a voltage within the part. This phenomenon is described by Faraday's Law of Induction. This induced voltage, in turn, drives strong, swirling electrical currents within the material, known as eddy currents.

Step 2: Joule Heating Generates the Heat

The generated eddy currents are not flowing through a perfect conductor. Every conductive material has some level of electrical resistance. As the eddy currents flow against this inherent resistance, they dissipate energy in the form of heat.

This effect is known as Joule heating (or resistive heating). The intense heat is generated rapidly and directly inside the material, making the process highly efficient.

Anatomy of an Induction Heating System

A functional induction system relies on a few critical components working in harmony.

The Power Supply: The Engine

The heart of the system is a solid-state power supply. It takes standard line power and converts it into the high-frequency alternating current required to drive the process. The frequency and power output are precisely controlled to manage the heating rate and temperature.

The Induction Coil: The Applicator

The induction coil, often made of copper tubing, is responsible for creating the magnetic field. Its shape is critical, as it focuses the magnetic field and determines where the heat will be generated on the workpiece. Coils are custom-designed for specific applications, from simple rings to complex, form-fitting shapes.

The Workpiece: The Heating Element

Unlike a conventional oven where heat is transferred via radiation or convection, in induction heating, the workpiece itself becomes the source of the heat. This is the most crucial concept to understand, as it explains the technology's speed and efficiency.

Ancillary Systems: The Support Crew

Because the process generates significant energy, supporting systems are essential. A chiller or water-cooling unit is almost always required to circulate coolant through the induction coil and power supply, preventing them from overheating.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Understanding its limitations is key to using it effectively.

Material Limitations: It Must Be Conductive

The primary requirement for induction heating is that the material must be electrically conductive. Ferrous metals like steel are excellent candidates, but other metals like aluminum and copper can also be heated effectively. Ceramics, plastics, and other insulators cannot be heated directly with this method.

Coil Design is Critical and Custom

The efficiency and precision of the heating process are directly tied to the design of the induction coil. A poorly designed coil can result in uneven heating or wasted energy. For complex parts, engineering a custom coil is often necessary, which can add to the initial setup cost and complexity.

High Initial System Cost

Induction heating systems, including the power supply, cooling unit, and custom coils, represent a significant capital investment compared to simpler technologies like torch heating or resistance furnaces. The return on this investment comes from high throughput, energy savings, improved quality, and repeatability over time.

Making the Right Choice for Your Goal

Selecting the right heating method depends entirely on your specific manufacturing or process objective.

- If your primary focus is high-volume hardening or annealing: Induction heating's speed and repeatability are ideal for automated production lines where thousands of parts must be processed identically.

- If your primary focus is precision joining like brazing or soldering: The ability to localize heat to a specific joint without affecting the rest of the assembly makes induction a superior choice for delicate work.

- If you are heating non-conductive materials or large, simple batches without a need for speed: A conventional resistance furnace may be a more cost-effective solution.

By understanding its principles and practical considerations, you can leverage induction heating as a powerful tool for modern manufacturing.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| Power Supply | Converts line power to high-frequency AC | Controls heating rate and temperature |

| Induction Coil | Generates a concentrated magnetic field | Custom design determines heat pattern |

| Workpiece | Heats itself internally via induced eddy currents | Must be electrically conductive |

| Cooling System | Prevents overheating of coil and power supply | Essential for sustained operation |

Ready to leverage the speed and precision of induction heating in your lab or production line? KINTEK specializes in high-performance lab equipment, including induction heating systems tailored for applications like brazing, hardening, and annealing. Our experts will help you select the right system to boost your efficiency, improve product quality, and achieve consistent results. Contact KINTEL today for a consultation and discover the right solution for your conductive material heating needs!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Double Plate Heating Press Mold for Lab

People Also Ask

- Why is a vacuum necessary for hot-pressing TiB2-TiN-WC composites? Ensure Chemical Purity and Material Strength

- Why is a vacuum hot pressing furnace essential for SiCf/Ti-43Al-9V? Achieving Full Densification and Purity

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- How does the vacuum hot pressing process affect the properties of finished materials? Maximize Density and Performance