At its core, annealing is a controlled heat treatment process that fundamentally alters a metal's internal structure. It works by heating the material to a specific temperature and then cooling it slowly, which primarily makes the metal softer, increases its ductility (its ability to be formed without breaking), and relieves internal stresses. This process can also significantly improve a material's electrical conductivity.

While annealing changes several properties, its fundamental purpose is to restore a metal's workability. It acts as a controlled "reset," reducing hardness and internal stress to allow for further shaping and machining or to prevent future distortion.

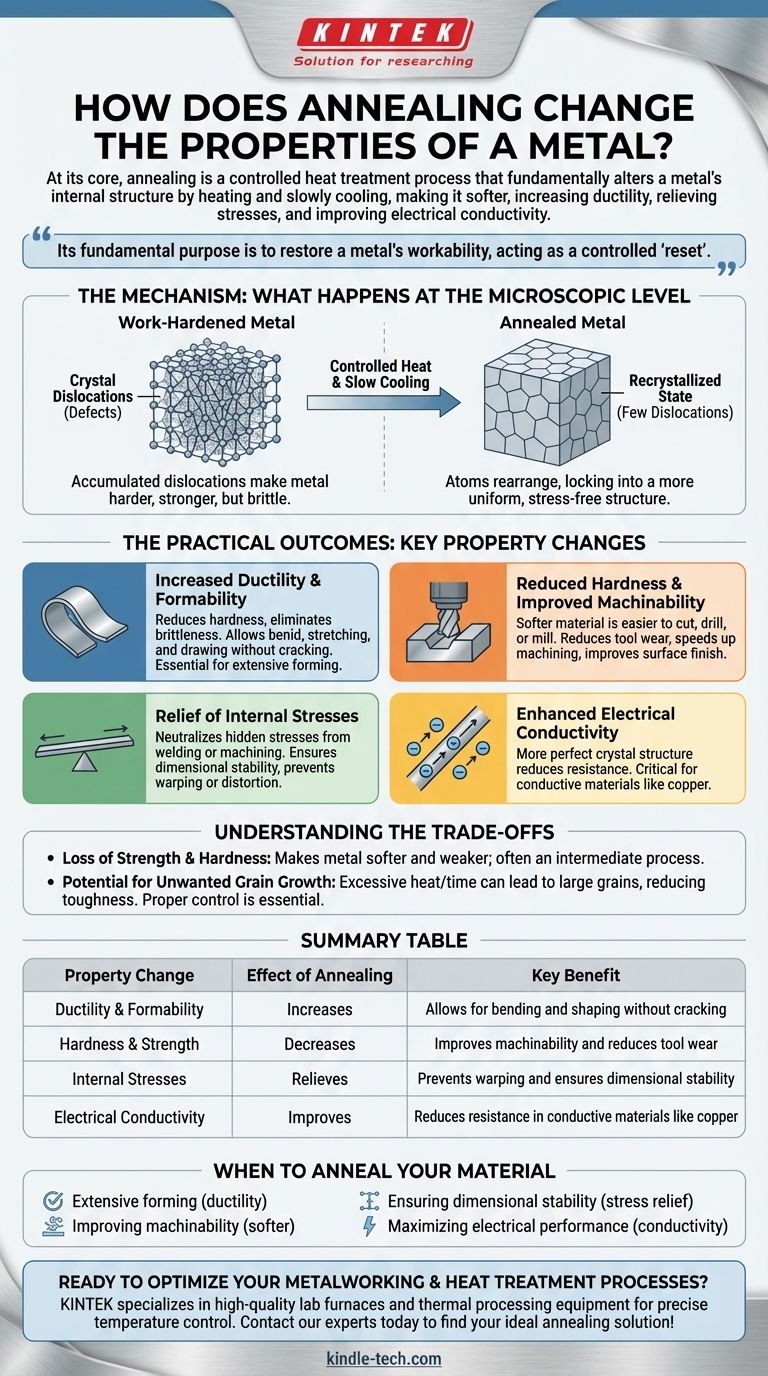

The Mechanism: What Happens at the Microscopic Level

To understand the results of annealing, you must first understand what it changes within the metal's crystal structure.

Reducing Crystal Dislocations

Processes like bending, rolling, or forging a metal create microscopic defects in its crystal lattice known as dislocations.

An accumulation of these dislocations makes the metal harder and stronger, but also more brittle and prone to cracking under further strain. This state is often referred to as "work-hardened."

The Role of Heat and Controlled Cooling

Annealing heats the metal to a temperature that allows its atoms to rearrange into a more orderly, "recrystallized" state with far fewer dislocations.

The slow, controlled cooling phase is critical. It allows this new, more uniform, and stress-free crystal structure to lock into place, effectively resetting the material's properties.

The Practical Outcomes: Key Property Changes

This microscopic reset translates directly into tangible changes in the metal's performance and behavior.

Increased Ductility and Formability

By reducing hardness and eliminating the brittleness from work-hardening, annealing restores ductility.

This makes the material more formable, allowing it to be bent, stretched, or drawn into a new shape without cracking. It is a common intermediate step in manufacturing processes that require extensive forming.

Reduced Hardness and Improved Machinability

A direct consequence of softening the metal is improved machinability.

Softer material is easier to cut, drill, or mill. This reduces wear and tear on cutting tools, can lower machining times, and often results in a better surface finish.

Relief of Internal Stresses

Processes like welding, grinding, and heavy machining can introduce significant internal stresses into a part.

These hidden stresses can cause the component to warp or distort over time, or worse, during a subsequent high-temperature process. Annealing neutralizes these stresses, ensuring dimensional stability.

Enhanced Electrical Conductivity

The dislocations and internal stresses in a work-hardened metal's crystal lattice impede the flow of electrons.

By creating a more perfect and orderly crystal structure, annealing reduces electrical resistance and improves conductivity, a critical benefit for materials like copper used in electrical applications.

Understanding the Trade-offs

Annealing is a powerful tool, but its application comes with clear trade-offs that must be managed.

Loss of Strength and Hardness

The primary trade-off is simple: annealing makes a metal softer and weaker. The same process that increases ductility and machinability reduces the material's tensile strength and its resistance to wear and deformation.

Annealing as an Intermediate Step

Because of this loss of strength, annealing is often an intermediate process, not the final one. It is used to make a material workable. After forming or machining, the part may require a different heat treatment, like quenching and tempering, to restore the final desired hardness and strength.

Potential for Unwanted Grain Growth

If the annealing temperature is too high or the time is too long, the crystal grains within the metal can grow excessively large. This can negatively impact the material's toughness and other mechanical properties. Proper process control is essential.

When to Anneal Your Material

Applying this knowledge requires aligning the process with your specific engineering or manufacturing goal.

- If your primary focus is preparing for extensive forming: Use annealing to restore ductility and prevent cracking during deep drawing, stamping, or bending operations.

- If your primary focus is improving machinability: Anneal the workpiece before complex milling or turning to reduce tool wear, speed up the process, and improve surface finish.

- If your primary focus is ensuring dimensional stability: Anneal parts after welding or heavy grinding to relieve internal stresses and prevent warping in service or during later heat treatments.

- If your primary focus is maximizing electrical performance: Use annealing to repair the crystal lattice in conductive materials like copper, thereby reducing electrical resistance.

Ultimately, annealing is a strategic tool for manipulating a material's state, enabling processes that would otherwise be impractical or impossible.

Summary Table:

| Property Change | Effect of Annealing | Key Benefit |

|---|---|---|

| Ductility & Formability | Increases | Allows for bending and shaping without cracking |

| Hardness & Strength | Decreases | Improves machinability and reduces tool wear |

| Internal Stresses | Relieves | Prevents warping and ensures dimensional stability |

| Electrical Conductivity | Improves | Reduces resistance in conductive materials like copper |

Ready to optimize your metalworking and heat treatment processes? The precise temperature control required for effective annealing is critical. KINTEK specializes in high-quality lab furnaces and thermal processing equipment, providing the reliable tools your laboratory needs to achieve perfect results every time.

Contact our experts today to find the ideal annealing solution for your specific materials and applications!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the significance of using a solution treatment furnace for 316L cladding? Restore Corrosion Resistance

- What are the advantages of insulation in a furnace? Maximize Efficiency, Performance, and Lifespan

- Why steam is added in pyrolysis furnace? Enhance Product Quality & Control Reaction Pathways

- What is the arc melting technique? Master High-Purity Metal Melting for Refractory Alloys

- Can stainless steel be brazed? Yes, with the right techniques to overcome chromium oxide

- What furnace is used for annealing? The Ultimate Guide to Vacuum and Controlled Atmosphere Furnaces

- How does pyrolysis of plastic work? Unlock Value from Waste Plastic

- Why is a heating system with dynamic vacuum required for FJI-H14 activation? Ensure Peak Adsorption Performance