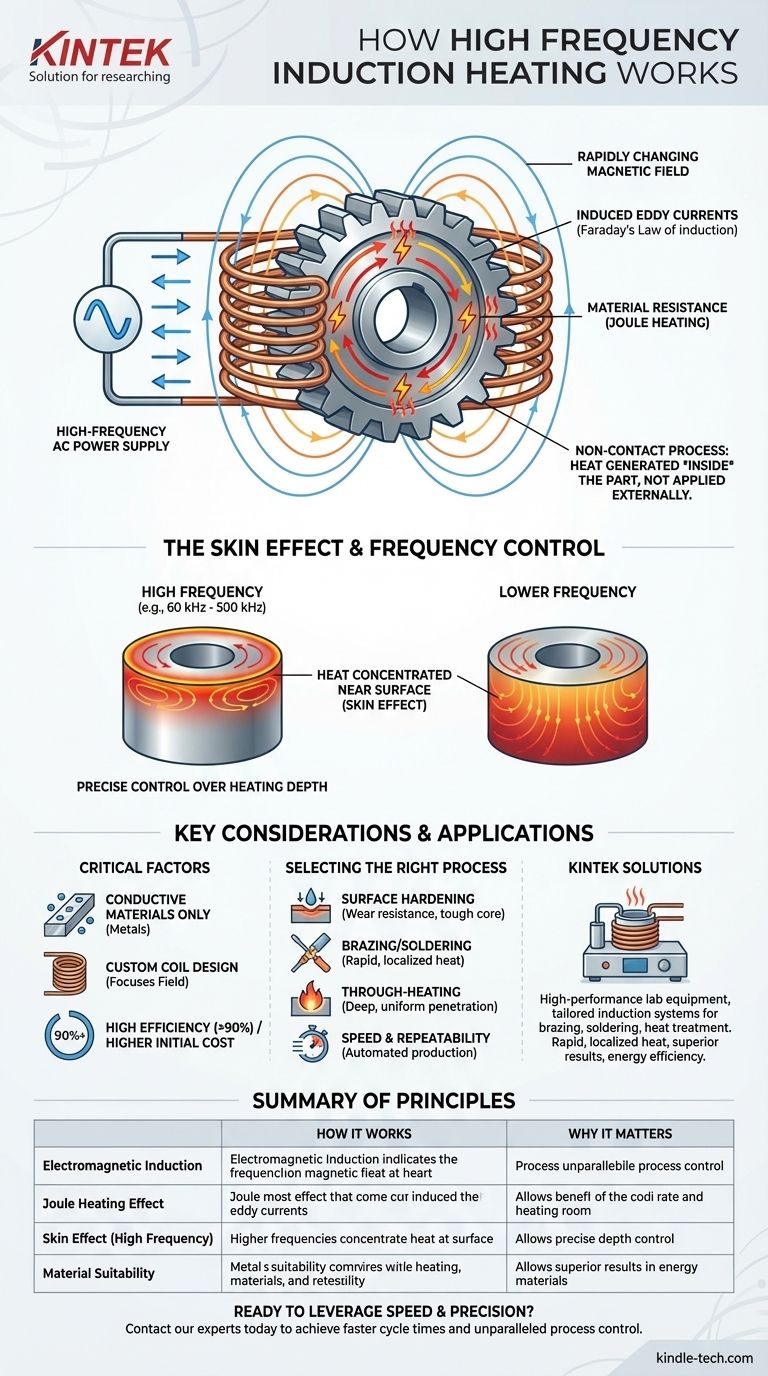

At its core, high-frequency induction heating is a non-contact process that uses electromagnetic principles to generate intense heat directly within a conductive material. An alternating current is passed through a specially designed coil, creating a rapidly changing magnetic field that induces electrical currents in the target part. The material’s own resistance to these currents is what generates precise, rapid, and localized heat.

The fundamental advantage of induction heating is not just heating an object, but transforming the object itself into the source of the heat. This allows for unparalleled speed, control, and energy efficiency by eliminating the need for slow, conventional heat transfer.

The Core Principles: From Magnetism to Heat

Induction heating is a direct application of two fundamental physics principles: Faraday's Law of Induction and the Joule heating effect. The process occurs in a clear sequence.

Step 1: The Alternating Magnetic Field

The process begins with a high-frequency power supply sending alternating current (AC) through a copper induction coil. This coil, often shaped to conform to the part being heated, acts as the primary circuit.

The flow of high-frequency AC generates a powerful and rapidly alternating magnetic field in the space around and within the coil.

Step 2: Inducing Eddy Currents

When an electrically conductive workpiece, such as a steel gear or aluminum tube, is placed within this magnetic field, the field induces circulating electrical currents within the metal.

These small, circular flows of current are known as eddy currents. This phenomenon is described by Faraday's Law of Induction, which states that a changing magnetic field will induce a voltage (and thus a current) in a conductor.

Step 3: Generating Heat Through Resistance

The induced eddy currents are not able to flow through the metal unimpeded. They encounter the material's natural electrical resistivity.

This resistance to the current flow generates friction and intense heat, a principle known as Joule heating. The heat is generated inside the part itself, not applied to its surface from an external source.

Why "High Frequency" Matters

The frequency of the alternating current is a critical variable that dictates how the part is heated. High-frequency systems typically operate in a range from 60 kHz to 500 kHz.

The Skin Effect

The most important consequence of using high frequencies is a phenomenon called the skin effect. It dictates that the higher the frequency, the more the induced eddy currents concentrate near the surface of the workpiece.

This means heat is generated in a very thin, defined layer at the surface, rather than deep within the part.

Controlling the Depth of Heat

This ability to control the heating depth is a key advantage. A very high frequency (e.g., 400 kHz) might only heat the outer 0.5mm of a steel part, while a lower frequency (e.g., 10 kHz, which is technically "medium frequency") would penetrate much deeper.

This control allows engineers to precisely tailor the heating process to the application.

Understanding the Trade-offs and Key Considerations

While powerful, induction heating is not a universal solution. Its effectiveness depends on specific factors.

Material Must Be Conductive

The primary requirement for induction heating is that the workpiece must be electrically conductive. It works exceptionally well on metals like steel, copper, brass, and aluminum but cannot be used to directly heat insulators like plastics, glass, or ceramics.

The Critical Role of Coil Design

The induction coil is not a generic component. Its geometry—the shape, size, and distance from the workpiece—is critical. It focuses the magnetic field and determines the resulting heat pattern.

Effective induction heating almost always requires a coil designed and tuned specifically for the part and the desired outcome.

High Efficiency vs. Initial Cost

Induction systems are extremely energy-efficient, often exceeding 90% efficiency. This is because the energy is transferred directly into the part with minimal heat loss to the surrounding environment.

However, the initial investment for a high-frequency power supply, cooling system, and custom coils can be significantly higher than for a conventional oven or torch.

Making the Right Choice for Your Application

Selecting the right heating process depends entirely on your objective.

- If your primary focus is surface hardening: High-frequency induction is ideal for creating a hard, wear-resistant outer case while leaving the core of the component ductile and tough.

- If your primary focus is brazing or soldering: Induction provides rapid, localized heat to the joint area, allowing for strong, clean bonds without distorting or annealing the entire assembly.

- If your primary focus is heating the entire part (through-heating): A lower-frequency induction system is better suited for achieving deep and uniform heat penetration for applications like forging or forming.

- If your primary focus is speed and repeatability: The precise control and rapid heating cycles of induction make it superior for automated, high-volume production lines where consistency is paramount.

By understanding these principles, you can leverage induction heating to achieve manufacturing outcomes that are faster, cleaner, and more precise than conventional methods allow.

Summary Table:

| Key Factor | How It Works | Why It Matters |

|---|---|---|

| Electromagnetic Induction | AC current in a coil creates a magnetic field, inducing eddy currents in the workpiece. | Heat is generated inside the material itself, not applied externally. |

| Joule Heating Effect | The material's resistance to eddy currents converts electrical energy into intense heat. | Enables rapid and highly efficient heating with minimal energy loss. |

| Skin Effect (High Frequency) | Higher frequencies concentrate heat near the surface of the part. | Allows precise control over heating depth for applications like surface hardening. |

| Material Suitability | Works on electrically conductive metals (steel, copper, aluminum). | Ideal for metalworking but not suitable for insulating materials like plastics or ceramics. |

Ready to leverage the speed and precision of induction heating in your lab or production line?

KINTEK specializes in high-performance lab equipment, including induction heating systems tailored for applications like brazing, soldering, and heat treatment. Our solutions deliver the rapid, localized heat you need for superior results and energy efficiency.

Contact our experts today to discuss how we can help you achieve faster cycle times and unparalleled process control.

Visual Guide

Related Products

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is induction heating also known as? The Science of Eddy Current Heating Explained

- Is induction hardening a heat treatment process? Achieve Superior Surface Hardening for Critical Components

- What is the function of a vacuum induction melting furnace? Essential Guide for High-Purity FeCrAl Alloy Production

- What is VIM in steel making? Discover the Process for Ultra-Pure, High-Performance Alloys

- What is the capacity of an induction furnace? Find the Right Size for Your Lab or Foundry

- What frequency is used for induction heating? Select the Right Range for Your Application

- How efficient are induction furnaces? Unlock Faster Melting & Superior Quality

- What is the temperature range of an induction furnace? From 1250°C to Over 2000°C for Your Specific Application