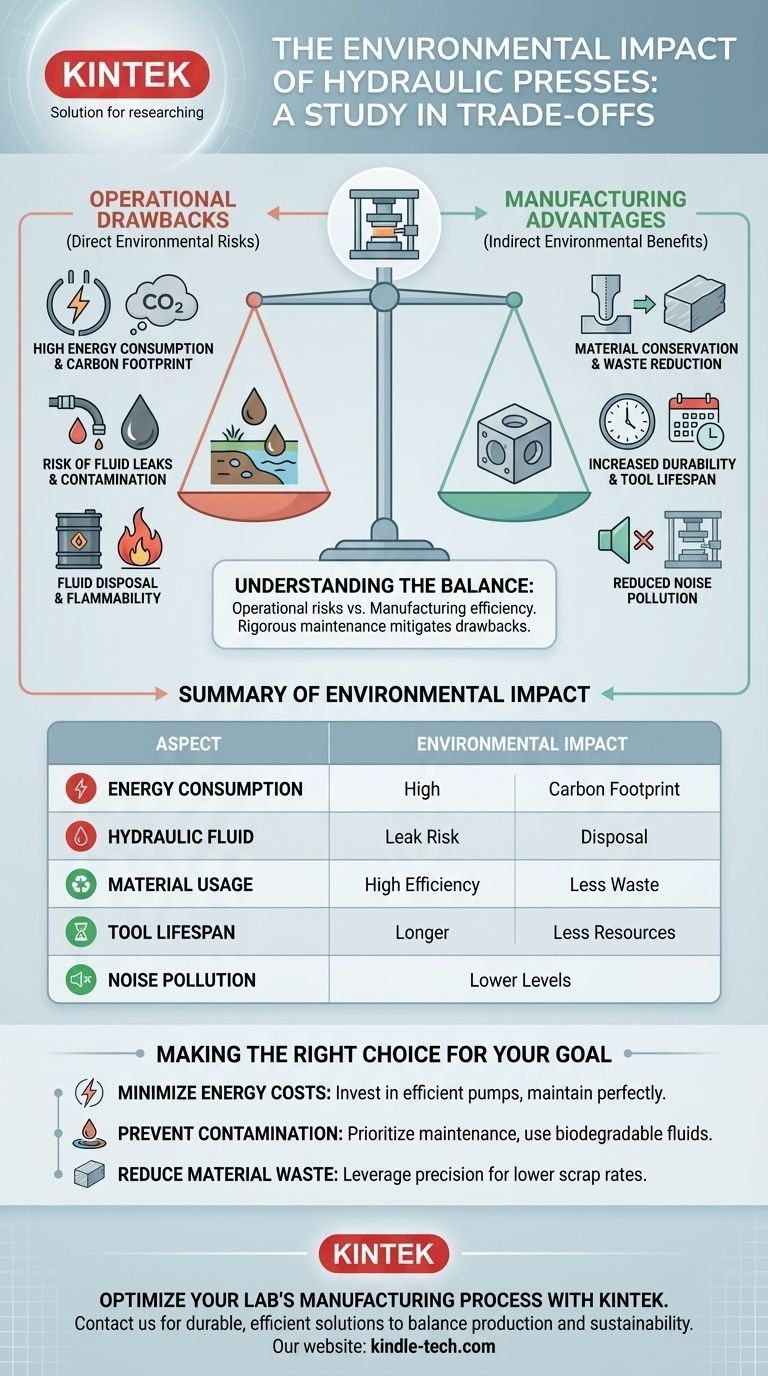

At its core, a hydraulic press impacts the environment through two primary avenues: its high energy consumption, which creates a carbon footprint, and the potential for hydraulic fluid leaks, which can contaminate soil and water. However, these operational drawbacks are often balanced by significant manufacturing advantages, such as superior material conservation and reduced production waste.

The environmental profile of a hydraulic press is a study in trade-offs. Its operational phase carries clear environmental risks related to energy use and potential fluid spills, but its efficiency in the manufacturing process can lead to a net positive impact by reducing material scrap and extending tool life.

How a Hydraulic Press Works

To understand its environmental impact, we must first understand its mechanism. A hydraulic press operates on a simple but powerful principle known as Pascal's Law.

The Role of Hydraulic Fluid

A pump moves hydraulic fluid (typically an oil) into a cylinder. This fluid cannot be compressed, so as more is pumped in, it exerts immense pressure. This pressure is the key to the machine's power.

Energy and Pressure Generation

The system applies a small force over a small area (the plunger) to generate a massive force over a larger area (the ram). This multiplication of force requires a powerful pump, which is the primary source of the machine's energy consumption.

The Direct Environmental Drawbacks

The day-to-day operation of a hydraulic press presents clear environmental challenges that require active management.

High Energy Consumption and Carbon Footprint

The pumps that pressurize the hydraulic fluid consume a significant amount of electricity. Unless the facility is powered by renewable sources, this high energy consumption translates directly into a carbon footprint from the burning of fossil fuels.

The Risk of Hydraulic Fluid Leaks

By far the most direct environmental hazard is the potential for hydraulic fluid leakage. Hoses, seals, and fittings can fail, releasing oil into the surrounding environment. Petroleum-based hydraulic fluids can contaminate soil and groundwater, posing a long-term ecological risk.

Fluid Disposal and Flammability

Used hydraulic fluid must be collected and disposed of as hazardous waste, adding an operational and environmental burden. Furthermore, some types of hydraulic fluids are flammable, creating a safety and environmental risk in the event of a fire.

The Indirect Environmental Advantages

While the operational risks are clear, the benefits of using a hydraulic press in manufacturing offer a powerful environmental counterargument.

Material Conservation and Waste Reduction

The immense, evenly distributed pressure of a hydraulic press allows for the precise forming and shaping of materials. This often results in significantly less scrap and material waste compared to traditional machining or cutting processes, conserving raw resources.

Increased Durability and Tool Lifespan

Because the force is controlled and applied without the shock of a mechanical press, the dies and tools used in a hydraulic press often have a longer lifespan. This durability reduces the environmental impact associated with manufacturing, transporting, and disposing of replacement tools.

Reduced Noise Pollution

Compared to mechanical stamping presses, which generate loud, sharp impacts, hydraulic presses are significantly quieter. This reduction in noise pollution is a direct benefit to the immediate workplace environment and surrounding community.

Understanding the Trade-offs

The choice to use a hydraulic press involves weighing its operational footprint against its manufacturing efficiency.

Operational Impact vs. Manufacturing Efficiency

The core trade-off is clear: you accept a higher operational energy cost and the inherent risk of fluid leaks in exchange for a manufacturing process that uses less raw material and creates less scrap waste. The "greener" choice depends on which factor is more significant for a given project.

The Critical Role of Maintenance

Many of the press's environmental drawbacks can be mitigated. A rigorous maintenance schedule is not just a disadvantage; it is the primary tool for preventing leaks, ensuring the machine runs efficiently, and minimizing its energy use. Neglecting maintenance directly increases the machine's negative environmental impact.

Making the Right Choice for Your Goal

Your decision should be guided by your primary environmental and production priorities.

- If your primary focus is minimizing operational energy costs: You must invest in a modern press with an energy-efficient pump system and ensure it is perfectly maintained to prevent pressure losses that waste power.

- If your primary focus is preventing environmental contamination: Your top priorities must be a robust, preventative maintenance schedule to eliminate leaks and the selection of biodegradable hydraulic fluids where feasible.

- If your primary focus is reducing material waste in production: A hydraulic press is an excellent choice, as its precision and power can dramatically lower scrap rates compared to alternative forming methods.

By understanding this balance, you can implement strategies to leverage the press's manufacturing benefits while actively managing its operational footprint.

Summary Table:

| Aspect | Environmental Impact |

|---|---|

| Energy Consumption | High, leading to a significant carbon footprint. |

| Hydraulic Fluid | Risk of leaks contaminating soil/water; requires proper disposal. |

| Material Usage | High efficiency, leading to significant material conservation and less waste. |

| Tool Lifespan | Longer tool life reduces resource consumption for replacements. |

| Noise Pollution | Lower noise levels compared to mechanical presses. |

Optimize Your Lab's Manufacturing Process with KINTEK

Struggling to balance production efficiency with environmental responsibility? KINTEK specializes in providing durable and efficient lab equipment, including hydraulic presses, designed to help you achieve superior material conservation and reduce waste. Our expertise ensures you get the right equipment to meet your sustainability goals while maintaining high performance.

Let us help you make an informed choice that benefits both your production line and the planet. Contact KINTEK today for a personalized consultation and discover how our solutions can enhance your lab's efficiency and environmental profile.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the function of an ultra-high pressure hydraulic press in ceramic composites? Achieving High-Density Densification

- How do power presses work? Unlock High-Speed Metal Forming and Stamping

- How accurate is the XRF measurement? Unlock the True Potential of Your Material Analysis

- Importance of Precision Hydraulic Pressing in TRISO Fuel Pellet Fabrication: Ensure Integrity and Performance

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What technical value does a four-column hydraulic press provide? Optimize Your Composite Powder Fabrication Today

- What is the difference between fused beads and pressed pellets? Choose the Right XRF Sample Prep Method

- How often do hydraulics need maintenance? A Guide to Condition-Based Reliability