In short, price is a direct reflection of a hydraulic machine's performance capabilities, but not just in terms of raw power. While a higher price tag often correlates with higher tonnage, the most significant performance gains come from improved component quality, control precision, and structural rigidity. These factors determine the machine's accuracy, speed, and long-term reliability far more than tonnage alone.

The price of a hydraulic machine is not just about the force it can produce. It is fundamentally an investment in repeatability, control, and operational uptime, which are the true drivers of performance in any professional setting.

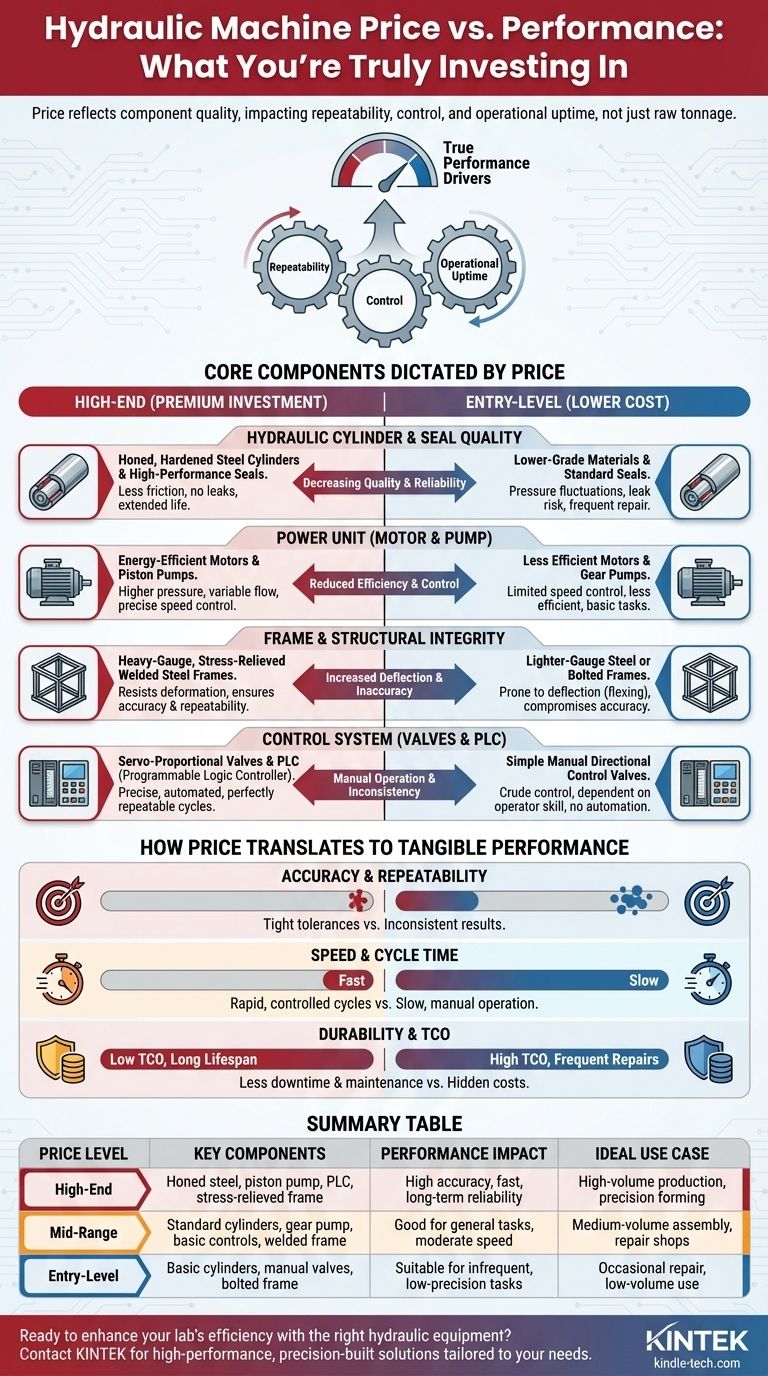

The Core Components Dictated by Price

The cost of a hydraulic press is determined by the quality and sophistication of its core systems. A higher initial investment directly translates to higher-grade components that deliver superior performance.

The Hydraulic Cylinder and Seal Quality

A machine's ability to deliver consistent force without failure begins with the cylinder and its seals.

Higher-priced machines use honed, hardened steel cylinders and high-performance seals. This results in less internal friction, prevents fluid leaks, and dramatically extends the operational life before maintenance is required.

Cheaper alternatives may use lower-grade materials and standard seals, leading to pressure fluctuations, a higher likelihood of leaks, and more frequent downtime for repairs.

The Power Unit (Motor and Pump)

The "heart" of the machine is its hydraulic power unit, consisting of the electric motor and the pump.

Premium machines feature energy-efficient motors paired with piston pumps. These pumps can handle higher pressures and offer variable flow, enabling precise control over the ram's speed.

Entry-level machines typically use less efficient motors and simpler gear pumps. These are reliable for basic tasks but offer limited control over speed and are generally less efficient under sustained use.

The Frame and Structural Integrity

A machine's performance under load is entirely dependent on the rigidity of its frame. This is one of the most critical, and often invisible, differentiators.

Expensive presses feature heavy-gauge, welded steel frames that are often stress-relieved after fabrication. This process prevents the frame from deforming under pressure, ensuring the press is accurate and repeatable.

Lower-cost machines may use lighter-gauge steel or bolted-together frames. These are prone to deflection (flexing) under maximum load, which compromises the accuracy of any pressing or forming operation.

The Control System (Valves and PLC)

The "brains" of the machine dictate its precision and automation capability.

High-performance machines utilize servo-proportional valves managed by a PLC (Programmable Logic Controller). This allows an operator to precisely program the ram's position, speed, and pressure, enabling complex, automated, and perfectly repeatable cycles.

Basic machines use simple manual directional control valves. These are operated by a hand lever, offering crude control that is dependent on operator skill and unsuitable for high-precision or production work.

How Price Translates to Tangible Performance

The quality of the components directly impacts the metrics that matter most in a production or repair environment.

Accuracy and Repeatability

This is the ability to produce the same result every single cycle. A rigid frame and a sophisticated PLC control system are essential for holding tight tolerances. A machine that flexes or has inconsistent hydraulic control cannot be repeatable.

Speed and Cycle Time

In a production setting, cycle time is money. A higher-end power unit and control system allow for rapid ram approach, a controlled pressing speed, and a quick retraction. This can dramatically increase throughput compared to a slow, manually operated press.

Durability and Total Cost of Ownership

A higher initial price often leads to a lower total cost of ownership (TCO). Premium components, from seals to pumps, are designed for longevity and require less maintenance. This means less downtime, fewer repair bills, and a longer machine lifespan.

Understanding the Trade-offs

Choosing a hydraulic machine is not about buying the most expensive option; it's about matching the machine's capabilities to the job's demands.

The "Good Enough" Principle

For an auto shop that presses bearings a few times a week, a simple, manually controlled press with a bolted frame is perfectly adequate. The extreme precision and speed of a production machine would be an unnecessary expense.

The Hidden Costs of a Low-Price Machine

Placing a low-cost machine in a high-volume production role is a false economy. The costs will quickly accumulate from scrapped parts due to inaccuracy, lost production during frequent downtime, and the need for premature replacement.

Application-Specific Design

The price also reflects specialization. A press designed for high-speed stamping has different features and costs than one designed for slow, high-tonnage compression molding. Paying for features you don't need, like complex automation for a simple repair task, is not a good investment.

Making the Right Choice for Your Goal

Select a machine based on a clear understanding of your primary operational requirement.

- If your primary focus is occasional repair or low-volume assembly: A lower-priced machine with a focus on a solid frame is often the most cost-effective choice, as speed and control are secondary.

- If your primary focus is high-volume production: Investing in a machine with a high-performance power unit and PLC controls is critical for minimizing cycle times and ensuring consistent part quality.

- If your primary focus is high-precision forming or molding: Prioritize a machine with a heavy, stress-relieved welded frame and servo-hydraulic controls, as its ability to resist deflection is paramount.

Ultimately, evaluating a hydraulic machine requires you to look beyond the price tag and focus on the value it delivers to your specific operation.

Summary Table:

| Price Level | Key Components | Performance Impact | Ideal Use Case |

|---|---|---|---|

| High-End | Honed steel cylinders, piston pumps, PLC controls, stress-relieved frame | High accuracy, fast cycle times, long-term reliability | High-volume production, precision forming |

| Mid-Range | Standard cylinders, gear pumps, basic controls, welded frame | Good for general tasks, moderate speed and accuracy | Medium-volume assembly, repair shops |

| Entry-Level | Basic cylinders, manual valves, bolted frame | Suitable for infrequent, low-precision tasks | Occasional repair, low-volume use |

Ready to enhance your lab's efficiency with the right hydraulic equipment?

At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored to your specific needs. Whether you're in high-volume production or require precision for R&D, our hydraulic machines are engineered for repeatability, control, and operational uptime—ensuring you get the best return on your investment.

Don't let a mismatched machine slow you down. Contact us today to discuss your requirements and discover how KINTEK can support your laboratory's success with reliable, precision-built solutions.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- Why KBr disc is used in IR spectroscopy? Achieve High-Resolution Analysis of Solid Samples

- What is a KBr press? Creating Transparent Pellets for Accurate FT-IR Analysis

- What is the maximum force of a hydraulic press? Discover How Force is Generated and Scaled

- What is a BARS press? Discover the Engineering Secrets to Growing Large, Gem-Quality Diamonds

- What are the factors that affect pellet quality? Master KBr Pellet Prep for Flawless FTIR Results

- What is the function of a high-pressure hydraulic press? Optimize Silicide Bulk Material Preparation

- How many PSI is a hydraulic press? Unlocking the Real Power Behind Tonnage

- What is the purpose of the XRF test? Rapid, Non-Destructive Elemental Analysis