In a hydraulic system, pressure is the agent of force. It is the fundamental mechanism used to transmit energy from a power source, like a pump, to an actuator, like a cylinder, enabling the system to perform work. Without pressure, the hydraulic fluid has no ability to move a load or overcome resistance.

Pressure is the indispensable tool that allows a hydraulic system to multiply force and do work. However, managing it is a delicate balance; it is also the primary driver of system stress, heat generation, and inefficiency.

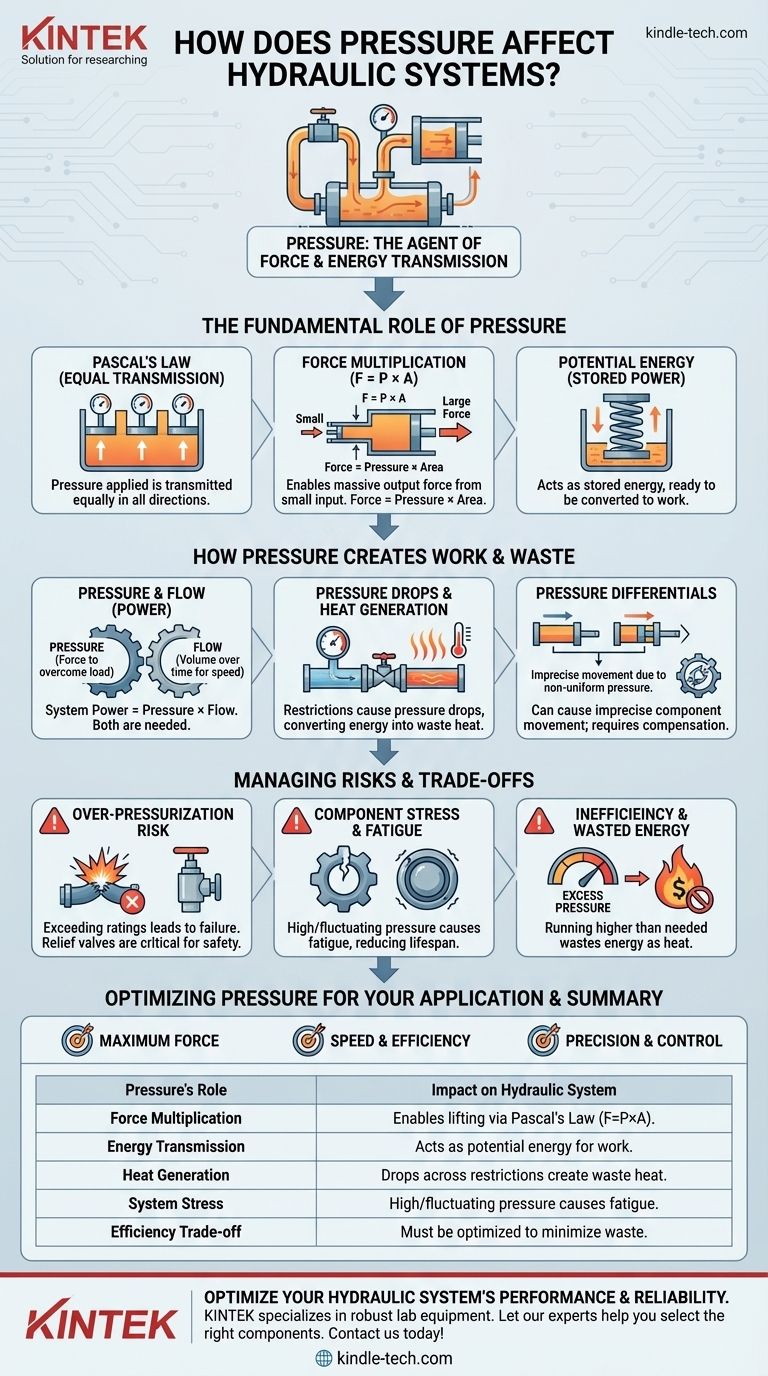

The Fundamental Role of Pressure

To understand a hydraulic system, you must first understand the behavior of pressure within a confined fluid. This is the bedrock on which all hydraulic principles are built.

Pascal's Law: The Core Principle

The operation of every hydraulic system is governed by Pascal's Law. This principle states that pressure applied to a confined, incompressible fluid is transmitted equally in all directions throughout the fluid.

This means the pressure reading at the pump is, in an ideal state, the same pressure being exerted on a piston hundreds of feet away.

Force Multiplication: The Power of Hydraulics

The true power of hydraulics comes from using this uniform pressure to multiply force. The relationship is defined by the formula: Force = Pressure × Area.

By applying pressure to a small piston (requiring a small input force) and transmitting it to a large piston, you generate a massive output force. This is how a small lever can lift a multi-ton excavator bucket.

Pressure as Potential Energy

Think of pressure as stored energy. When the pump works to push fluid against resistance, it builds pressure, effectively loading the system with potential energy, much like compressing a spring.

When a control valve is opened, this potential energy is converted to kinetic energy (fluid flow), which drives an actuator to perform work.

How Pressure Creates Both Work and Waste

While pressure is necessary for work, its behavior throughout the system dictates the overall efficiency, speed, and heat generation.

The Relationship Between Pressure and Flow

Pressure and flow are the two primary variables in a hydraulic system. Pressure is the force required to overcome a load, while flow is the volume of fluid moved over time, which determines the actuator's speed.

A system's power is a direct product of these two factors. You need sufficient pressure to move the load and sufficient flow to move it at the desired speed.

Pressure Drops and Heat Generation

Any obstruction or restriction in the fluid's path—such as pipes, hoses, fittings, and valves—causes a pressure drop. This lost pressure energy is converted directly into heat.

Unnecessary restrictions, undersized lines, or running a system at a higher pressure than needed are the most common sources of excess heat, which is a sign of wasted energy.

Compensating for Pressure Differentials

In complex machinery, pressure is not always perfectly uniform, especially during dynamic movements. These pressure differences can cause components to move imprecisely.

Advanced systems use mechanical solutions, such as interlinked guides, to compensate for these pressure imbalances and ensure components act in perfect synchronization.

Understanding the Trade-offs and Risks

Operating a hydraulic system is a constant exercise in managing the trade-offs associated with pressure. Higher pressure is not always better.

The Risk of Over-Pressurization

The most immediate danger is over-pressurization. Every component in a system has a maximum pressure rating. Exceeding it can lead to burst hoses, failed seals, and catastrophic, dangerous failures.

Pressure relief valves are critical safety components designed to divert excess flow and cap the maximum system pressure to a safe limit.

Component Stress and Fatigue

Even when operating below the maximum rating, high or fluctuating pressure places constant stress on all system components. This leads to metal fatigue and reduces the service life of cylinders, pumps, hoses, and seals.

Inefficiency and Wasted Energy

Running a system at a higher pressure than the load requires is fundamentally inefficient. If a task only requires 1,500 PSI but the system's relief valve is set to 3,000 PSI, all excess pressure is converted directly to wasted heat.

Optimizing Pressure for Your Application

The correct pressure setting is entirely dependent on the work being done. Your goal is to use the least amount of pressure required to accomplish the task reliably and efficiently.

- If your primary focus is maximum force: You must ensure your pump can generate the required pressure and that all components are rated to handle it safely.

- If your primary focus is speed and efficiency: You must focus on designing a system with adequate flow and minimal pressure drops by using properly sized lines and valves.

- If your primary focus is precision and control: Your goal is stable pressure regulation and managing the dynamic fluctuations that occur during operation.

Ultimately, mastering pressure is about treating it not as a brute-force tool, but as a precise instrument to be controlled and optimized.

Summary Table:

| Pressure's Role | Impact on Hydraulic System |

|---|---|

| Force Multiplication | Enables lifting heavy loads via Pascal's Law (Force = Pressure × Area). |

| Energy Transmission | Acts as potential energy, converted to kinetic energy to perform work. |

| Heat Generation | Pressure drops across restrictions convert energy into waste heat. |

| System Stress | High or fluctuating pressure causes component fatigue and failure risk. |

| Efficiency Trade-off | Must be optimized for the specific task to minimize energy waste. |

Optimize your hydraulic system's performance and reliability. Understanding pressure is key to maximizing force, control, and efficiency while minimizing wear and heat generation. KINTEK specializes in providing robust lab equipment and consumables, serving the precise needs of laboratories and research facilities. Let our experts help you select the right components for your application. Contact us today to discuss your specific hydraulic system requirements!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy