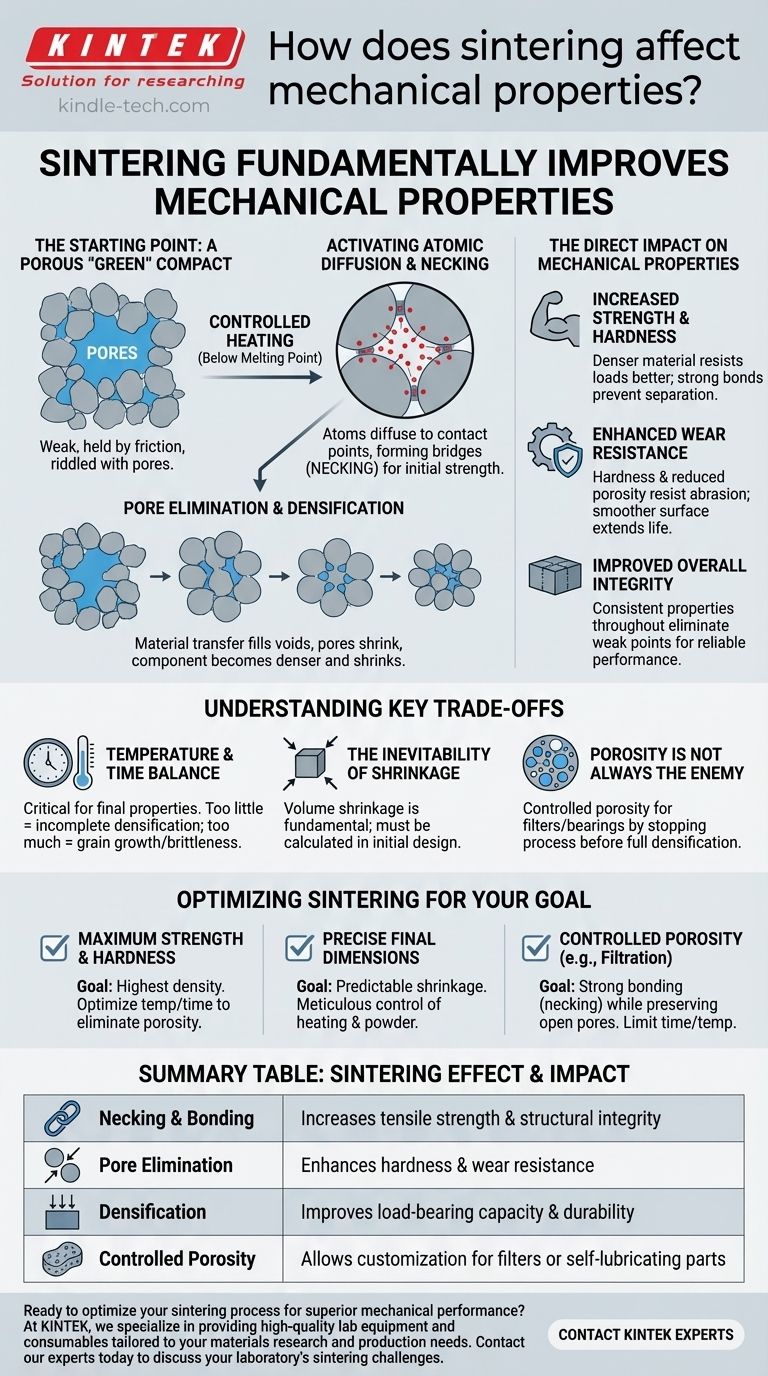

In short, sintering fundamentally improves mechanical properties. It is the critical process that transforms a compacted collection of individual powder particles into a solid, cohesive object with significant strength, hardness, and wear resistance. This transformation occurs by heating the material below its melting point, which activates atomic-level bonding between particles.

The core principle is that sintering systematically removes the empty spaces, or pores, between powder particles. By driving atomic diffusion to create strong bonds and a denser structure, it turns a weak "green" compact into a robust, mechanically sound component.

The Core Mechanism: From Powder to Solid

To understand how sintering enhances mechanical properties, you must first visualize the material's transformation from a loose aggregate into a unified solid.

The Starting Point: A Porous "Green" Compact

Before sintering, the process starts with a "green" compact. This is powdered material that has been pressed into a desired shape but possesses very little strength. It is held together by mechanical interlocking and friction, but it is riddled with pores.

Activating Atomic Diffusion

The key to sintering is controlled heating. Applying high temperatures, yet staying below the material's melting point, provides the thermal energy necessary to excite the atoms. This energy allows atoms to move, or diffuse, across the surfaces and boundaries of the individual particles.

Necking and Particle Bonding

In the initial stages, diffusion is most active at the points where particles touch. Atoms migrate to these contact points, forming small bridges or "necks." This necking is the first step in creating a truly bonded, cohesive structure, which marks the initial increase in strength.

Pore Elimination and Densification

As the process continues, material transfer fills the voids between particles. The network of pores gradually shrinks and is eliminated, causing the entire component to shrink and become significantly denser. This densification is directly responsible for the dramatic improvement in mechanical performance.

The Direct Impact on Mechanical Properties

The structural changes that occur during sintering have a direct and predictable effect on the final component's performance.

Increased Strength and Hardness

A denser material with fewer pores has a greater cross-sectional area to resist applied loads. The strong, fused bonds between particles prevent them from being pulled apart or displaced. This directly translates to higher tensile strength and greater hardness.

Enhanced Wear Resistance

The increase in hardness and the reduction of surface porosity make the material much more resistant to abrasion and wear. A smooth, dense surface is less likely to have particles torn away by friction, extending the component's operational life.

Improved Overall Integrity

By creating a unified and cohesive structure, sintering ensures that the mechanical properties are consistent throughout the component. This eliminates the weak points inherent in an un-sintered powder compact, resulting in a reliable and predictable engineering material.

Understanding the Key Trade-offs

While sintering is a powerful process, its successful application requires controlling several critical variables and understanding the inherent compromises.

The Temperature and Time Balance

The final properties are highly dependent on the sintering temperature and duration. Insufficient heat or time will result in incomplete densification and poor mechanical properties. Conversely, excessive heat can lead to undesirable grain growth, which can sometimes make the material more brittle.

The Inevitability of Shrinkage

Because sintering works by eliminating pores, volume shrinkage is a fundamental part of the process. This change in dimension must be precisely calculated and accounted for in the initial design of the green compact to achieve the desired final geometry.

Porosity is Not Always the Enemy

While maximum density is often the goal for structural parts, some applications require controlled porosity. Components like filters or self-lubricating bearings rely on an interconnected network of pores, which is achieved by intentionally stopping the sintering process before full densification.

Optimizing Sintering for Your Goal

The way you approach sintering should be dictated by the primary requirement of your final component.

- If your primary focus is maximum strength and hardness: Your goal is to achieve the highest possible density by optimizing the temperature and time to eliminate nearly all porosity.

- If your primary focus is precise final dimensions: Your goal is to meticulously control the heating cycle and starting powder characteristics to ensure predictable and repeatable shrinkage.

- If your primary focus is controlled porosity (e.g., for filtration): Your goal is to encourage strong particle bonding (necking) while carefully limiting the time and temperature to preserve a network of open pores.

Mastering the sintering process gives you direct control over a material's density, and therefore, its final mechanical destiny.

Summary Table:

| Sintering Effect | Impact on Mechanical Property |

|---|---|

| Necking & Bonding | Increases tensile strength and structural integrity |

| Pore Elimination | Enhances hardness and wear resistance |

| Densification | Improves load-bearing capacity and durability |

| Controlled Porosity | Allows customization for filters or self-lubricating parts |

Ready to optimize your sintering process for superior mechanical performance? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your materials research and production needs. Whether you're working on achieving maximum density for structural components or controlled porosity for specialized applications, our solutions ensure precision and reliability. Contact our experts today to discuss how we can support your laboratory's sintering challenges and help you achieve your material property goals.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.