In materials science, sintering is the primary thermal process used to reduce or eliminate porosity in a compacted powder. By heating a material below its melting point, individual particles bond together, causing the object to shrink and the void spaces (pores) between the particles to decrease in size and number. This process transforms a fragile "green" component into a dense, coherent solid.

Sintering fundamentally reduces porosity by using thermal energy to drive particles to bond and densify. However, this is a balancing act; the same parameters that eliminate pores also coarsen the material's microstructure, creating a critical trade-off between achieving high density and maintaining other desirable properties like mechanical strength.

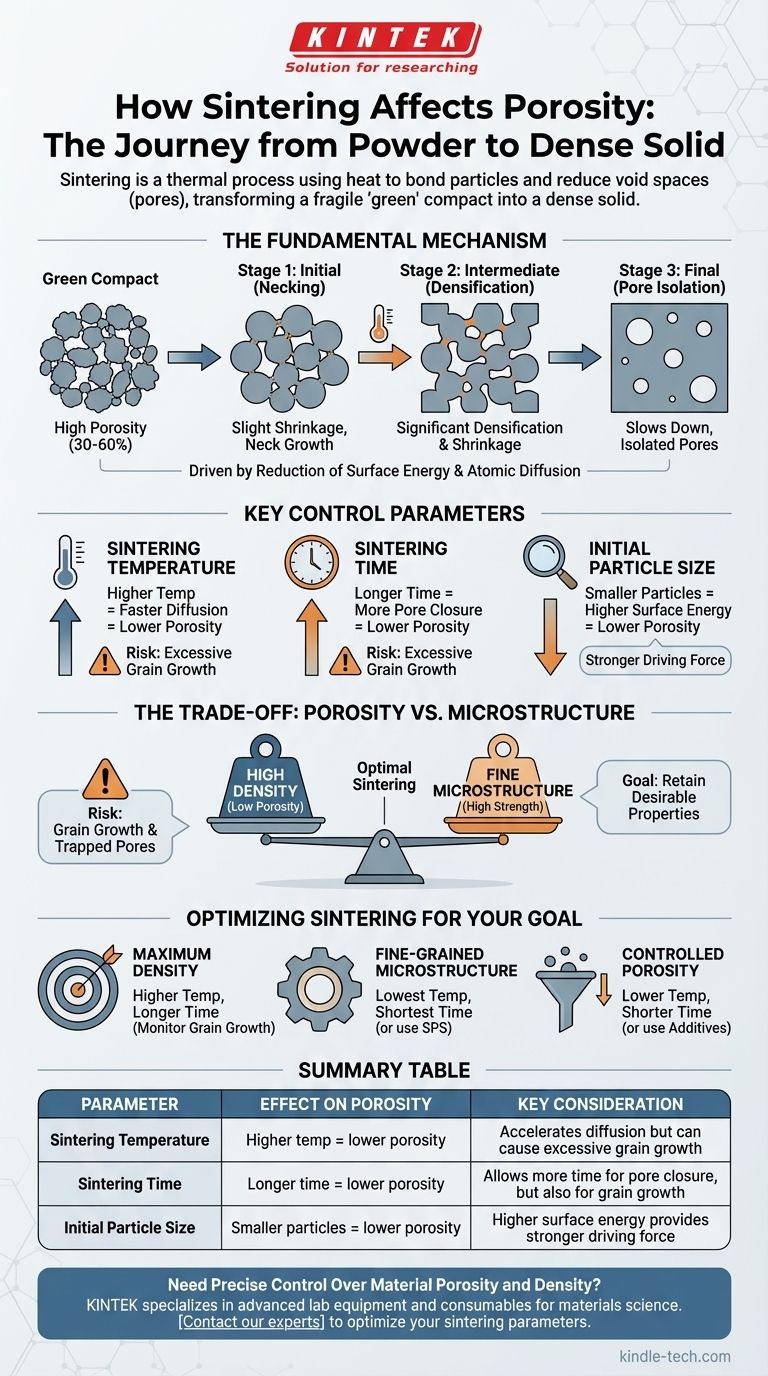

The Fundamental Mechanism: How Sintering Reduces Porosity

To control porosity, you must first understand the physics driving the process. Sintering is a diffusion-controlled phenomenon driven by the reduction of surface energy.

The Starting Point: The "Green" Compact

Before sintering, particles are mechanically pressed into a shape called a green compact. This object has significant porosity, often between 30% and 60% of its total volume, consisting of a network of voids between the particles.

The Driving Force: Reducing Surface Energy

A fine powder has an enormous amount of surface area, which corresponds to high surface energy. Systems naturally seek their lowest energy state. Sintering provides the thermal energy that allows atoms to move, or diffuse, to reduce this total surface area by forming solid bonds between particles and eliminating the void spaces.

The Stages of Densification

The reduction in porosity occurs in predictable stages:

- Initial Stage: As the material heats, "necks" begin to form at the contact points between adjacent particles. This initial bonding slightly increases the component's strength and causes a small amount of shrinkage and porosity reduction.

- Intermediate Stage: The necks grow, and the pores form an interconnected, channel-like network. This is the stage where the most significant densification and shrinkage occur, drastically reducing porosity.

- Final Stage: The pore channels pinch off, leaving behind isolated, spherical pores. The rate of densification slows considerably as it becomes much harder for the remaining voids to be eliminated.

Key Control Parameters and Their Impact

The outcome of sintering is dictated by several key parameters. The reference to the Ti-15Mo alloy correctly identifies temperature and time as the primary levers.

The Effect of Sintering Temperature

Temperature is the most powerful factor controlling densification. Higher temperatures dramatically increase the rate of atomic diffusion, accelerating neck growth and pore closure. This leads to lower final porosity in a shorter amount of time.

The Effect of Sintering Time

At a given temperature, a longer sintering time allows the diffusion process to proceed further. This results in greater densification and lower porosity, as more voids have time to shrink and close.

The Influence of Initial Particle Size

Smaller starting particles possess higher surface energy, creating a stronger driving force for sintering. Consequently, fine powders can often be sintered to a high density at lower temperatures or for shorter times compared to coarser powders.

Understanding the Trade-offs: Porosity vs. Microstructure

Simply maximizing temperature and time to eliminate all porosity is rarely the optimal strategy. Sintering forces a critical trade-off between density and the final microstructure of the material.

The Problem of Grain Growth

The same thermal energy that drives densification also drives grain growth. As particles bond and pores are eliminated, the individual crystalline grains tend to merge and grow larger. Excessive grain growth can be detrimental to mechanical properties like strength and fracture toughness.

The Risk of Trapped Pores

In the final stage of sintering, rapid grain growth can cause a grain boundary to sweep past a pore, trapping it inside the grain. These intraranular pores are extremely difficult to remove and act as stress concentrators, compromising the material's integrity.

The Balancing Act

The goal of a well-designed sintering process is often to achieve the highest possible density while minimizing grain growth. This requires carefully optimizing the heating rate, peak temperature, and hold time to keep the material in the intermediate stage for as long as possible before grain growth accelerates.

Optimizing Sintering for Your Goal

Your approach to sintering should be tailored to the desired outcome for your component. Use these principles as a guide.

- If your primary focus is achieving maximum density: You will need to use higher temperatures or longer sintering times, but you must carefully monitor the process to avoid excessive grain growth.

- If your primary focus is preserving a fine-grained microstructure for mechanical strength: Use the lowest possible temperature and shortest time that achieves the minimum required density, or consider advanced techniques like Spark Plasma Sintering (SPS).

- If your primary focus is creating a controlled, porous structure (e.g., for filters or implants): Deliberately use lower temperatures, shorter times, or space-holding additives to halt the sintering process before full densification occurs.

By understanding these principles, you can manipulate the sintering process to precisely engineer the final porosity and performance of your material.

Summary Table:

| Parameter | Effect on Porosity | Key Consideration |

|---|---|---|

| Sintering Temperature | Higher temp = lower porosity | Accelerates diffusion but can cause excessive grain growth |

| Sintering Time | Longer time = lower porosity | Allows more time for pore closure, but also for grain growth |

| Initial Particle Size | Smaller particles = lower porosity | Higher surface energy provides a stronger driving force for densification |

Need precise control over material porosity and density for your laboratory components? KINTEK specializes in advanced lab equipment and consumables for materials science. Our expertise in thermal processing solutions can help you optimize your sintering parameters to achieve the perfect balance of density and microstructure for your specific application. Contact our experts today to discuss how we can support your research and production goals.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the use of muffle furnace in pharmaceuticals? Essential for Purity & Quality Control

- What is furnace lining? The Engineered System Protecting Your High-Temperature Processes

- What does a high ash content mean? A Guide to Material Quality & Contamination

- What is the use of muffle furnace in food laboratory? Essential for Accurate Nutritional Analysis & Quality Control

- What is the difference between oven incubator and muffle furnace? Choose the Right Lab Heating Tool