In short, increasing the sintering temperature generally increases the final density of a material, but only up to an optimal point. Temperature provides the thermal energy required for atoms to diffuse and eliminate the pores between powder particles. Exceeding the optimal temperature can lead to undesirable effects like excessive grain growth or even melting, which can compromise the material's properties and structural integrity.

The core principle is that sintering is a thermally activated process. The goal is not simply to use the highest possible temperature, but to precisely control the temperature to maximize atomic diffusion for densification while minimizing negative side effects.

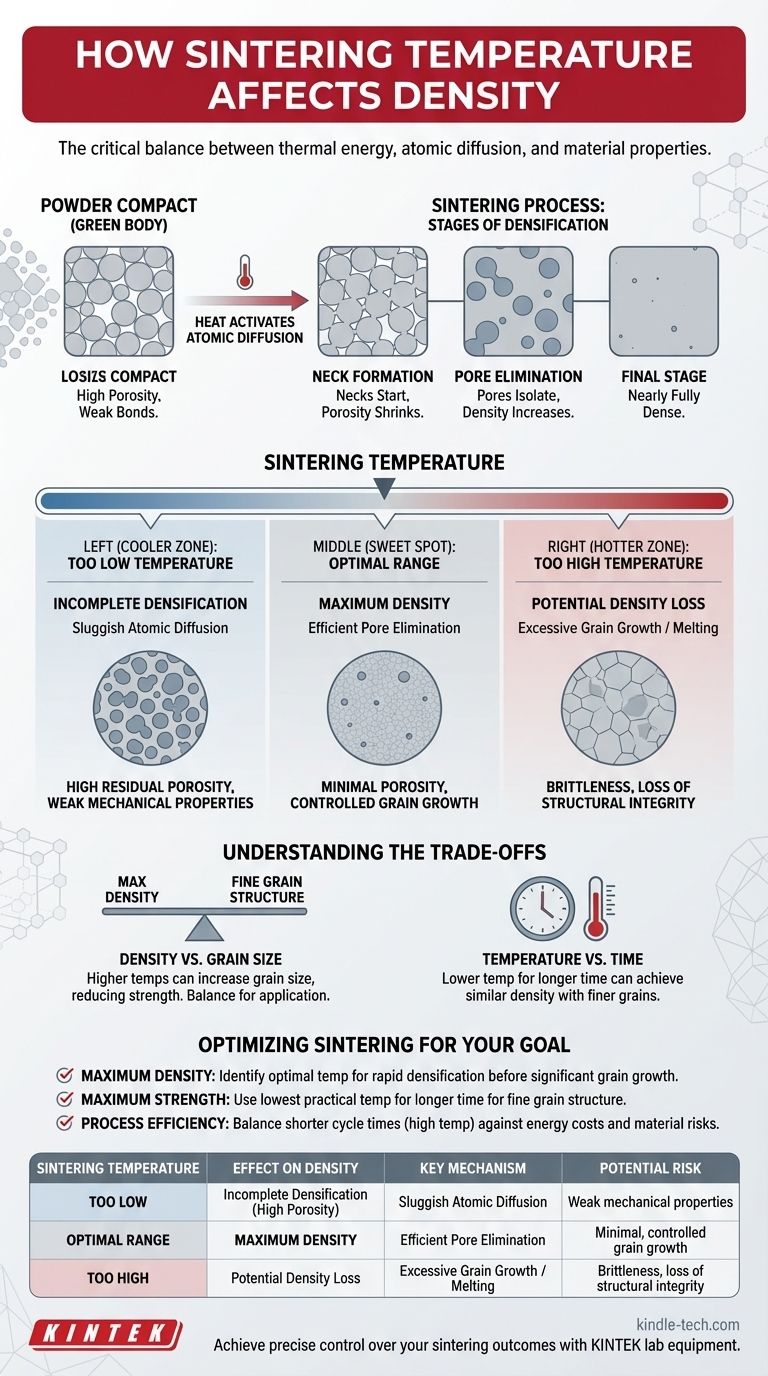

The Fundamental Mechanism: From Powder to Solid

The Initial State: A Powder Compact

Sintering begins with a "green body." This is a collection of individual powder particles that have been compressed into a desired shape but are held together by weak mechanical forces.

This green body contains a significant amount of empty space, or porosity, between the particles. The primary goal of sintering is to eliminate this porosity and transform the loose powder compact into a dense, solid object.

Activating Atomic Diffusion

Heat is the engine of sintering. As you increase the temperature, you are supplying thermal energy to the atoms within the powder particles.

This energy allows atoms to move, or diffuse, from the bulk of the particles to the points of contact between them. This atomic movement begins to form "necks" that connect adjacent particles, effectively starting to weld them together.

The Stages of Densification

As the temperature is held over time (a process called "soaking"), this atomic diffusion continues, and the part progresses through distinct stages.

The initial necks grow larger, pulling the particle centers closer together. The network of pores shrinks from interconnected channels into isolated, spherical pockets. In the final stage, these isolated pores are gradually eliminated as atoms diffuse to fill the voids, leading to a nearly fully dense material.

The Critical Role of Temperature

Finding the "Sweet Spot"

For every material, there is an optimal sintering temperature range. This is the temperature at which atomic diffusion is fast enough to achieve high density in a reasonable amount of time.

For example, a specific aluminum alloy might reach full density at 630°C. This temperature is high enough to activate rapid diffusion but low enough to avoid melting and loss of shape.

Below the Optimal Temperature: Incomplete Densification

If the sintering temperature is too low, atomic diffusion will be sluggish. Necks will form, but the process will be too slow to close the majority of the pores.

The result is a part with high residual porosity, poor bonding between particles, and consequently, weak mechanical properties.

Above the Optimal Temperature: The Risk of Grain Growth

If the temperature is too high, you introduce a competing mechanism: grain growth. The same atomic mobility that closes pores also allows smaller grains (individual crystals) to be consumed by larger ones.

While the part may be dense, excessively large grains can often make a material more brittle and reduce its overall strength and toughness.

Understanding the Trade-offs

Density vs. Grain Size

This is the classic trade-off in sintering. Pushing for the absolute maximum density by using very high temperatures often comes at the cost of increased grain size. In applications where mechanical performance is critical, a balance must be struck, sometimes accepting slightly lower density to maintain a fine, strong grain structure.

Temperature vs. Time

Density is a function of both temperature and time. You can often achieve the same final density by sintering at a lower temperature for a longer period. This approach is frequently used to limit grain growth when fine-grained microstructures are desired.

Energy Costs and Equipment

Higher sintering temperatures require more energy, increasing operational costs. They may also necessitate more advanced furnaces with specialized heating elements and atmospheres, representing a significant capital investment.

Optimizing Sintering for Your Goal

To properly control your process, you must see temperature not as a simple knob to turn up, but as a precise tool to be balanced against other variables like time and starting material.

- If your primary focus is achieving maximum density: Your goal is to identify the optimal temperature that provides rapid densification just before significant grain growth begins, and hold it for sufficient time.

- If your primary focus is maximizing mechanical strength: You may need to use the lowest practical temperature for a longer time, often combined with finer starting powders, to achieve good density while keeping the final grain size small.

- If your primary focus is process efficiency: You will need to balance the shorter cycle times of high-temperature sintering against the increased energy costs and the potential for compromised material properties.

Mastering sintering is about understanding and controlling these interconnected variables to reliably produce a part that meets its design intent.

Summary Table:

| Sintering Temperature | Effect on Density | Key Mechanism | Potential Risk |

|---|---|---|---|

| Too Low | Incomplete Densification (High Porosity) | Sluggish Atomic Diffusion | Weak mechanical properties |

| Optimal Range | Maximum Density | Efficient Pore Elimination | Minimal, controlled grain growth |

| Too High | Potential Density Loss | Excessive Grain Growth / Melting | Brittleness, loss of structural integrity |

Achieve precise control over your sintering outcomes with KINTEK.

Whether your goal is maximum density, superior mechanical strength, or optimal process efficiency, the right lab equipment is crucial. KINTEK specializes in high-performance sintering furnaces and consumables for laboratories, providing the precise temperature control and uniformity you need to master the trade-offs between density, grain size, and cycle time.

Let us help you optimize your process. Contact our experts today to discuss your specific material and application requirements.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What role does a vacuum hot pressing sintering furnace play for nanocopper? Achieve Maximum Densification Today

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What temperature does tungsten carbide sinter at? Master the 1350°C-1500°C Liquid-Phase Sintering Process