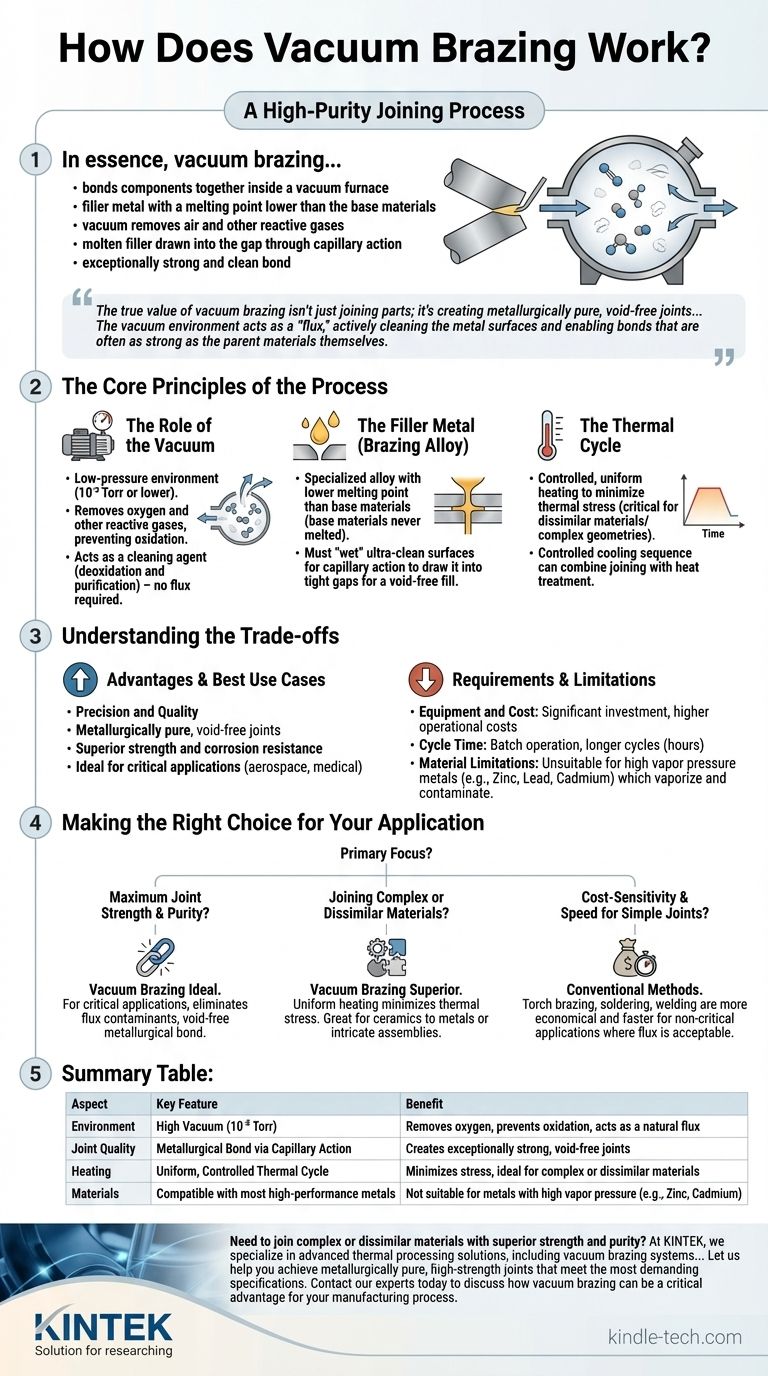

In essence, vacuum brazing is a high-purity joining process that bonds components together inside a vacuum furnace. A filler metal, with a melting point lower than the base materials, is placed at the joint. As the assembly is heated, the vacuum removes air and other reactive gases, allowing the molten filler to be drawn into the gap between the parts through capillary action, creating an exceptionally strong and clean bond upon cooling.

The true value of vacuum brazing isn't just joining parts; it's creating metallurgically pure, void-free joints with superior strength and corrosion resistance. The vacuum environment acts as a "flux," actively cleaning the metal surfaces and enabling bonds that are often as strong as the parent materials themselves.

The Core Principles of the Process

To understand how vacuum brazing works, it's crucial to see the vacuum not as an empty space, but as an active component in the process. It fundamentally changes the chemical environment in which the joint is formed.

The Role of the Vacuum

The low-pressure environment (typically 10⁻⁵ Torr or lower) is the defining feature and is responsible for several critical functions.

First, it removes oxygen and other reactive gases. This prevents the formation of oxides on the metal surfaces as they are heated. Oxides act as a barrier, preventing the filler metal from properly bonding to the base materials.

Second, the vacuum acts as a cleaning agent. It removes adsorbed surface contaminants and can even pull volatile elements out of the base metals themselves, a process known as outgassing. This deoxidation and purification इज what makes the process "fluxless."

The Filler Metal (Brazing Alloy)

The filler metal is a specialized alloy chosen for its specific melting temperature and its ability to bond with the parent materials.

Its melting point is always lower than the melting point of the components being joined. This is the fundamental difference between brazing and welding; the base materials are never melted.

When molten, the filler metal must "wet" the surfaces of the parent materials. Wetting is the ability of a liquid to spread across a solid surface. The ultra-clean, oxide-free surfaces created by the vacuum allow for perfect wetting.

This wetting enables capillary action, which is the force that draws the molten filler metal into the tight-fitting gaps of the joint, ensuring a complete, void-free fill.

The Thermal Cycle

The entire assembly is heated in a highly controlled manner inside the vacuum furnace.

The components are heated uniformly to the brazing temperature, which is just above the filler metal's melting point. This uniform heating minimizes thermal stress, which is especially critical when joining dissimilar materials or complex geometries.

After a set time at temperature to allow the filler to flow, the assembly is cooled in a controlled sequence. This cooling cycle can be tailored to achieve specific material properties, effectively combining the joining process with a heat treatment cycle.

Understanding the Trade-offs

While powerful, vacuum brazing is not the solution for every joining challenge. Its precision and quality come with specific requirements and limitations.

Equipment and Cost

Vacuum brazing requires a significant capital investment in a vacuum furnace and associated control systems. The operational costs, including energy consumption and maintenance, are also higher than simpler joining methods.

Cycle Time

The process инфекциозна a batch operation. The time required to pump down the vacuum, heat the parts, hold at temperature, and cool down can be several hours. This makes it less suitable for high-volume, low-margin production or rapid repairs.

Material Limitations

Certain materials are unsuitable for vacuum brazing. Metals with a high vapor pressure, such as zinc, lead, or cadmium, will vaporize in the vacuum at brazing temperatures. This not only ruins the part but also severely contaminates the furnace interior.

Making the Right Choice for Your Application

Selecting vacuum brazing depends entirely on the technical requirements of the final product.

- If your primary focus is maximum joint strength and purity: Vacuum brazing is ideal for critical applications like aerospace turbines or medical implants, as it eliminates flux contaminants and creates a void-free metallurgical bond.

- If your primary focus is joining complex or dissimilar materials: The uniform, controlled heating of vacuum brazing minimizes thermal stress, making it superior to localized methods like welding for joining ceramics to metals or intricate assemblies like heat exchangers.

- If your primary focus is cost-sensitivity and speed for simple joints: Conventional torch brazing, soldering, or welding are far more economical and faster for non-critical applications where a flux-based process is acceptable.

By understanding these principles, you can confidently determine when vacuum brazing is not just a joining method, but a critical manufacturing advantage.

Summary Table:

| Aspect | Key Feature | Benefit |

|---|---|---|

| Environment | High Vacuum (10⁻⁵ Torr) | Removes oxygen, prevents oxidation, acts as a natural flux |

| Joint Quality | Metallurgical Bond via Capillary Action | Creates exceptionally strong, void-free joints |

| Heating | Uniform, Controlled Thermal Cycle | Minimizes stress, ideal for complex or dissimilar materials |

| Materials | Compatible with most high-performance metals | Not suitable for metals with high vapor pressure (e.g., Zinc, Cadmium) |

Need to join complex or dissimilar materials with superior strength and purity?

At KINTEK, we specialize in advanced thermal processing solutions, including vacuum brazing systems. Our furnaces are designed to deliver the precise, controlled environments necessary for creating flawless bonds in critical applications like aerospace components and medical devices.

Let us help you achieve metallurgically pure, high-strength joints that meet the most demanding specifications.

Contact our experts today to discuss how vacuum brazing can be a critical advantage for your manufacturing process.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a high-performance vacuum system required for alloy distillation? Boost Purity with 10–15 Pa Control

- Why is vacuum drying equipment required for carbide production? Preserve Powder Purity & Prevent Cobalt Oxidation

- What is the primary function of a high-vacuum drying oven in the preparation of polymer electrolyte membranes?

- What is the operating temperature of a furnace? From Home Heating to Industrial Processing

- What critical conditions does a high-temperature furnace provide for 12% Cr steel? Master Long-Term Normalizing

- How to design a pyrolysis reactor? Optimize for Biochar, Bio-oil, or Syngas Yield

- What is the purpose of sintering in powder metallurgy? Transform Powder into High-Strength Parts

- Can you braze while in a vacuum? Achieve Flawless, Flux-Free Metal Joining