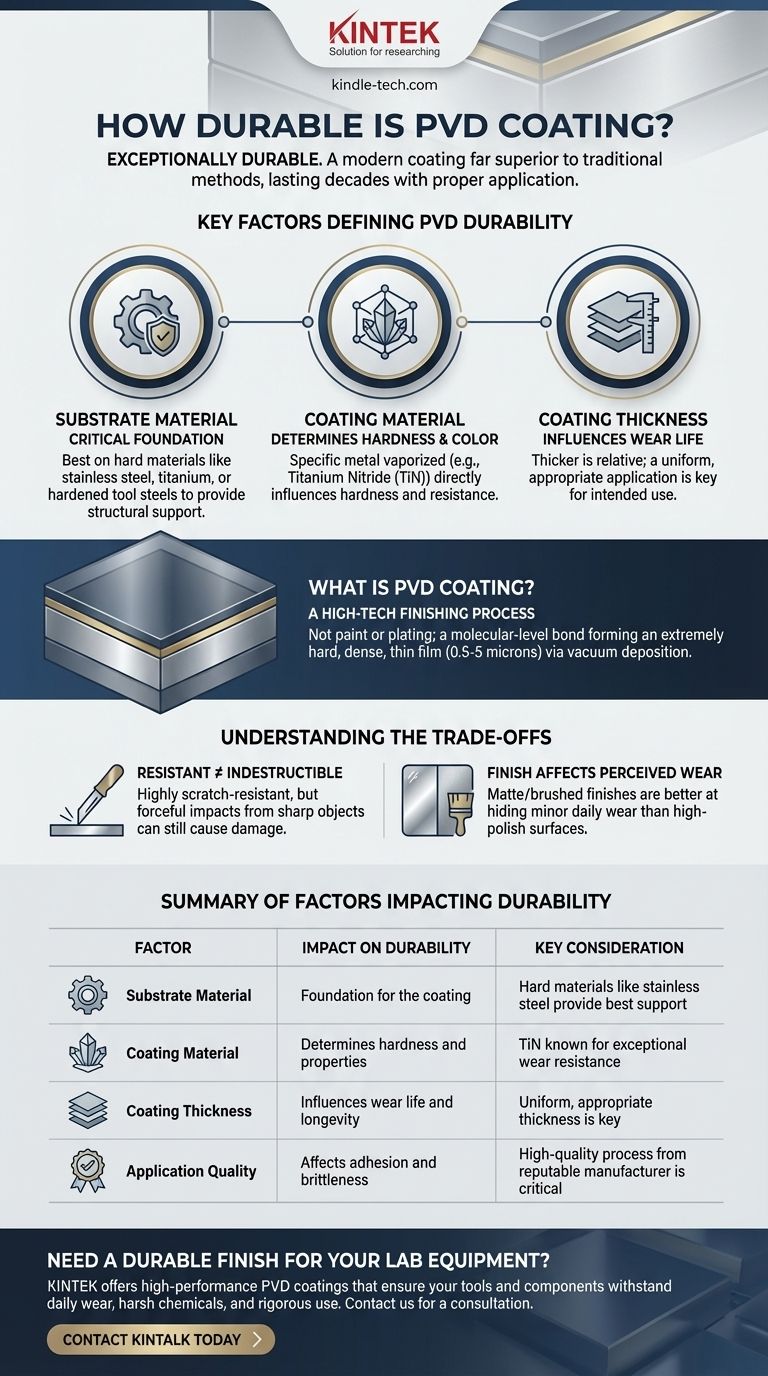

In short, PVD is exceptionally durable. Physical Vapor Deposition (PVD) is a modern coating process that creates a finish far superior to traditional methods like painting or plating. When applied correctly, a PVD coating can last for decades, offering superior resistance to scratches, corrosion, and tarnishing.

The true durability of a PVD coating is not a fixed number of years, but a direct result of three key variables: the quality of the base material it is applied to, the specific material used for the coating itself, and the thickness of the application.

What Is PVD Coating?

Physical Vapor Deposition is a high-tech finishing process that bonds a thin film of metal to a surface on a molecular level. It is not a liquid paint or a chemical bath, but an advanced vacuum deposition technique.

A Molecular-Level Bond

The process involves vaporizing a solid metal—such as titanium or zirconium—into a plasma within a vacuum chamber. This vapor then condenses onto the object being coated, forming a very thin (typically 0.5 to 5 microns) but extremely hard and dense layer.

The Role of the Substrate

The object being coated is called the substrate. The final properties and longevity of the PVD finish are intrinsically linked to the quality and hardness of this underlying material.

The Factors That Define PVD Durability

Not all PVD coatings are created equal. Their resilience depends entirely on the quality of the materials and the process itself.

The Substrate Material is Critical

A PVD coating is only as strong as its foundation. Applying a hard coating to a soft base metal will not prevent dents, which can cause the coating to flex and fail.

For this reason, PVD is most effective when applied to hard materials like stainless steel, titanium, or hardened tool steels. The strength of the substrate provides the structural support the thin coating needs to perform.

Coating Material Determines Hardness

The specific metal vaporized for the coating directly influences its hardness and color. Different materials offer different properties.

For example, Titanium Nitride (TiN) is a very common PVD material known for its gold tone and exceptional hardness, which significantly increases the surface's resistance to wear and fatigue.

Coating Thickness

Generally, a thicker coating provides more durability and a longer wear life. However, PVD is a micro-thin application, so "thicker" is relative. The key is ensuring the thickness is appropriate and uniform for the intended use of the object.

Understanding the Trade-offs

While PVD is a superior finish, it is important to have realistic expectations. Understanding its limitations is key to evaluating a product.

"Resistant" Does Not Mean "Indestructible"

PVD coatings are highly scratch-resistant, not scratch-proof. A forceful impact from a sharp, hard object can still gouge or chip the coating. Its primary strength lies in resisting the abrasion and scuffs of daily use.

The Quality of Application Matters

A poorly controlled PVD process can result in a brittle or poorly-adhered coating that will flake or wear away quickly. The reputation of the manufacturer and the quality of their process are just as important as the materials they use.

Finish Affects Perceived Wear

A high-polish, mirror-like PVD finish will show fine scratches and fingerprints more readily than a matte or brushed finish. While a matte surface may be technically just as durable, it is far more effective at hiding the minor signs of wear that accumulate over time.

Making the Right Choice for Your Goal

When assessing a PVD-coated product, consider what you need it to withstand.

- If your primary focus is daily wear (e.g., a watch, jewelry, or faucet): Prioritize coatings applied to a hard substrate like stainless steel, as this foundation prevents dings that can compromise the finish.

- If your primary focus is decorative use (e.g., indoor trim or fixtures): The specific substrate and coating thickness are less critical, as the item will not face constant abrasion or impact.

- If your primary focus is high-performance tools: Demand technical specifications. The exact coating compound (e.g., TiN, ZrN) and substrate alloy are paramount for endurance and performance.

Ultimately, a well-executed PVD coating on a quality base material offers one of the most resilient and long-lasting finishes available today.

Summary Table:

| Factor | Impact on Durability | Key Consideration |

|---|---|---|

| Substrate Material | Foundation for the coating | Hard materials like stainless steel provide the best support |

| Coating Material | Determines hardness and properties | Titanium Nitride (TiN) is known for exceptional wear resistance |

| Coating Thickness | Influences wear life and longevity | A uniform, appropriate thickness is key for the intended use |

| Application Quality | Affects adhesion and brittleness | A high-quality, controlled process from a reputable manufacturer is critical |

Need a Durable Finish for Your Laboratory Equipment or Components?

At KINTEK, we understand that durability is non-negotiable for lab equipment and consumables. Our expertise in high-performance coatings ensures your tools and components withstand daily wear, harsh chemicals, and rigorous use.

Let us help you select the right PVD coating solution to enhance the longevity and performance of your products.

Contact KINTALK today for a consultation and see how our durable coating solutions can benefit your laboratory.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating