The cost of firing an electric kiln is not a fixed number, but a variable you can calculate and control. For a typical hobbyist-sized kiln, a single bisque firing might cost between $9 and $20, while a glaze firing could range from $12 to $30. The exact price depends entirely on your kiln's power consumption, the length of the firing, and your local electricity rates.

The real cost of running a kiln isn't a mystery, but a simple calculation. By understanding the three core factors—kiln power (kW), firing time, and your electricity rate ($/kWh)—you can accurately budget for every firing and make informed decisions to optimize your studio's efficiency.

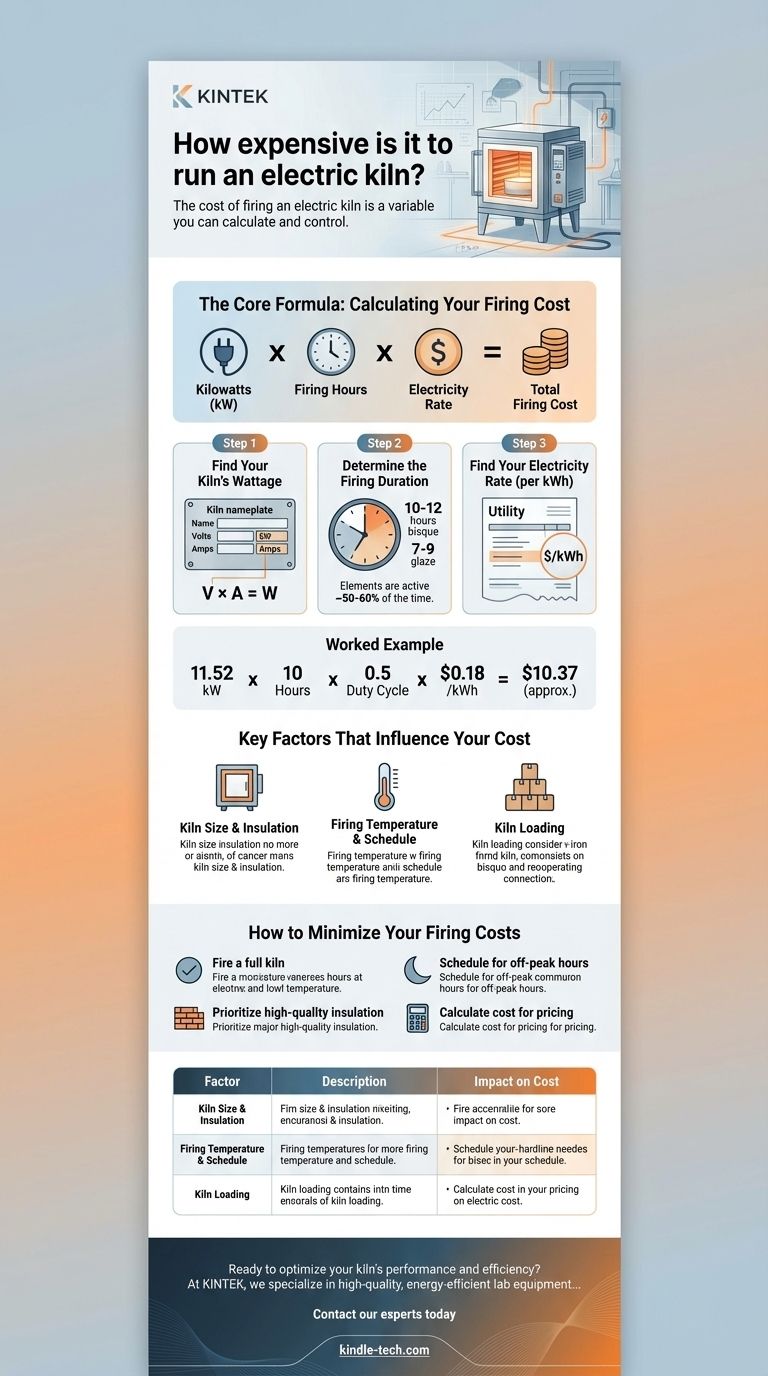

The Core Formula: Calculating Your Firing Cost

To determine the cost, you need three pieces of information. The basic formula is:

Kilowatts (kW) x Firing Hours x Electricity Rate = Total Firing Cost

Let's break down how to find each of these values.

Step 1: Find Your Kiln's Wattage

Your kiln's power is measured in watts (W) or kilowatts (kW). You can find this on the metal nameplate attached to the kiln's control box.

If the plate only lists Volts (V) and Amps (A), you can calculate the wattage yourself: Volts x Amps = Watts.

Since electricity is billed in kilowatt-hours, you must then convert watts to kilowatts by dividing by 1,000. For example, a kiln that is 240V and 48A uses 11,520 watts, or 11.52 kW.

Step 2: Determine the Firing Duration

This is the total time your firing program takes, from start to finish. A slow bisque firing might take 10-12 hours, while a cone 6 glaze firing could be 7-9 hours.

However, the kiln's heating elements are not on 100% of the time. The controller cycles them on and off to maintain the correct ramp rate. For a reliable estimate, you can assume the elements are actively drawing power for about 50-60% of the total firing duration.

For budgeting, using 50% (or 0.5) is a safe and common figure.

Step 3: Find Your Electricity Rate (per kWh)

Look at your most recent utility bill to find your electricity rate. It will be listed as a price per kilowatt-hour (kWh). This is the most significant variable, as rates can differ dramatically between regions.

Be aware if your plan has "time-of-use" rates, where electricity is cheaper during off-peak hours (like overnight) and more expensive during peak demand (like late afternoons).

Putting It All Together: A Worked Example

Let's calculate the cost for a common scenario:

- Kiln: A medium-sized kiln running at 11.52 kW.

- Firing Schedule: A 10-hour bisque fire.

- Electricity Rate: $0.18 per kWh.

- Duty Cycle Estimate: 50% (0.5).

The calculation would be:

11.52 kW x 10 Hours x 0.5 Duty Cycle x $0.18/kWh = $10.37

In this example, the 10-hour bisque firing costs just over ten dollars.

Key Factors That Influence Your Cost

The formula gives you a number, but understanding what influences that number is how you gain control.

Kiln Size and Insulation

Larger kilns naturally require more power to heat their internal volume. Just as important is the quality of the insulation—typically the thickness of the firebrick. A kiln with 3-inch thick brick will retain heat far better and use less energy than an older kiln with 2.5-inch brick.

Firing Temperature and Schedule

It takes more energy to reach higher temperatures. A cone 10 firing (around 2381°F / 1305°C) will always be more expensive than a cone 04 bisque fire (around 1945°F / 1063°C) in the same kiln.

Similarly, schedules with long, slow ramps or extended "hold" periods at peak temperature will increase the total time the elements are on, raising the cost.

Kiln Loading

An empty kiln is an expensive kiln. Firing a full load is far more energy-efficient because the pieces themselves become a thermal mass, retaining heat and helping the kiln maintain temperature with less work from the elements. This dramatically reduces the energy cost per piece.

Understanding the Trade-offs

Optimizing for cost sometimes involves balancing other factors.

The Cost of an Empty Firing

The most significant waste of energy is firing a kiln that is half-full. While you may be anxious to see your finished pieces, waiting until you have a full load can cut the energy cost per item in half. This is the classic trade-off between patience and efficiency.

Speed vs. Pottery Health

While a very fast firing schedule uses less electricity, it can introduce thermal shock, increasing the risk of cracks or dunting in your work. A slightly slower, more controlled schedule is often a worthwhile investment for a higher success rate.

Upfront Investment vs. Running Cost

A brand-new, well-insulated kiln is a significant upfront investment. However, its energy efficiency will save you money on every single firing compared to a cheaper or older, less-insulated model. Over years of use, the more efficient kiln often pays for the initial price difference through lower electricity bills.

How to Minimize Your Firing Costs

You can actively manage your expenses by applying these principles.

- If your primary focus is maximizing efficiency: Always fire a full kiln to take advantage of thermal mass and reduce the energy cost per item.

- If your primary focus is managing your budget: Check your utility for time-of-use rates and schedule firings for off-peak hours, such as overnight.

- If your primary focus is long-term savings: When buying a kiln, prioritize one with thicker, higher-quality insulation, as the upfront cost will be offset by lower energy consumption.

- If your primary focus is accurate pricing: Use the formula to calculate the cost for your specific kiln and rates, then add that cost into the price of your finished work.

By understanding these core principles, you transform firing costs from an unknown variable into a manageable and predictable part of your creative process.

Summary Table:

| Factor | Description | Impact on Cost |

|---|---|---|

| Kiln Power (kW) | Power consumption of the kiln. | Higher kW = Higher Cost |

| Firing Time (Hours) | Total duration of the firing cycle. | Longer Time = Higher Cost |

| Electricity Rate ($/kWh) | Cost per kilowatt-hour from your utility. | Higher Rate = Higher Cost |

| Kiln Load | How full the kiln is. | Full Load = Lower Cost Per Item |

| Insulation Quality | Thickness and quality of the kiln's firebrick. | Better Insulation = Lower Cost |

Ready to optimize your kiln's performance and efficiency?

At KINTEK, we specialize in high-quality, energy-efficient lab equipment, including electric kilns designed for superior insulation and precise temperature control. Whether you're a hobbyist or a professional studio, our kilns help you reduce running costs and achieve consistent results.

Contact our experts today to find the perfect kiln for your needs and start saving on every firing!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why are rotary kiln reactors widely utilized for large-scale biomass torrefaction? Optimize Your Thermal Processing

- What is the efficiency of a rotary kiln? Achieve Optimal Performance for Your Process

- How does a rotary kiln work? Unlock Continuous, High-Volume Thermal Processing

- What size is a rotary kiln? A Custom Solution for Your Process Needs

- What are the conditions for calcination reactions? Mastering Temperature and Atmosphere Control

- What are the industrial applications of fluidization? Unlock Efficient Heat & Mass Transfer for Your Process

- What are the hazards of plastic pyrolysis? Understanding the Environmental and Safety Risks

- How does catalyst work in pyrolysis? A Guide to Efficient and Selective Fuel Production