In short, Physical Vapor Deposition (PVD) is an excellent coating technology. It is not merely a paint or plating but a vacuum deposition process that fundamentally enhances a material's surface on a molecular level. This results in a finish that is exceptionally hard, durable, and corrosion-resistant while also offering a wide range of high-quality decorative options.

PVD coating is best understood as a strategic upgrade to a material's surface properties. It provides a measurable increase in functional performance—such as wear resistance and hardness—while simultaneously delivering a premium, long-lasting aesthetic finish that far surpasses traditional coating methods.

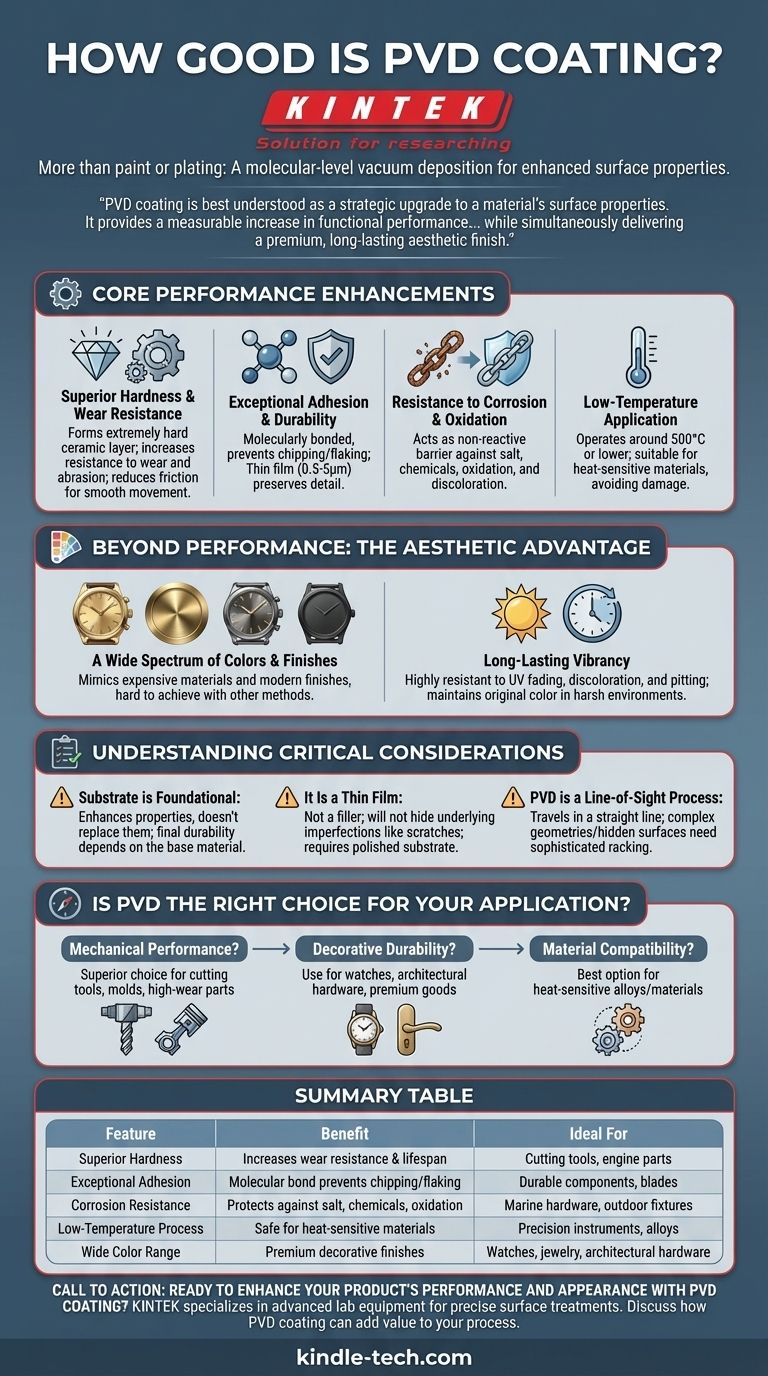

The Core Performance Enhancements of PVD

PVD coatings deliver significant functional advantages by altering the physical properties of the substrate's surface. This makes it a go-to choice for demanding industrial and mechanical applications.

Superior Hardness and Wear Resistance

PVD forms an extremely hard ceramic layer on the surface of a component. This dramatically increases its resistance to wear and abrasion.

The process also reduces the coefficient of friction, allowing parts to move more smoothly against each other. This is critical for cutting tools, engine components, and other high-wear parts where longevity is essential.

Exceptional Adhesion and Durability

Unlike paint, which can chip or flake, PVD coatings are molecularly bonded to the substrate. This creates outstanding adhesion.

Though the coating is very thin—typically between 0.5 and 5 microns—this bond makes it incredibly durable. The thinness also ensures that the fine details and sharpness of the original part, such as a blade's edge, are preserved.

Resistance to Corrosion and Oxidation

The deposited film acts as a chemically non-reactive barrier between the substrate and the environment.

This barrier provides high resistance to corrosion from salt, air, and other chemicals, as well as resistance to oxidation and discoloration.

Low-Temperature Application

PVD is a low-temperature process, typically operating around 500°C or lower.

This makes it suitable for coating heat-sensitive materials that would be damaged or distorted by higher-temperature coating processes like Chemical Vapor Deposition (CVD).

Beyond Performance: The Aesthetic Advantage

While its functional benefits are clear, PVD is also highly valued for its ability to produce superior decorative finishes that are both beautiful and resilient.

A Wide Spectrum of Colors and Finishes

PVD can create a vast range of colors and finishes that are difficult or impossible to achieve with other methods.

It can expertly mimic the appearance of expensive materials like gold, brass, and bronze, or create modern finishes like matte black and gunmetal grey for products like watches, jewelry, and architectural hardware.

Long-Lasting Vibrancy

PVD finishes are highly resistant to fading from UV light, discoloration, and pitting.

This makes them ideal for products exposed to harsh environments, such as fixtures on coastal properties, as they maintain their original color and vibrancy with minimal maintenance.

Understanding the Critical Considerations

To leverage PVD effectively, you must understand its limitations. The quality of the result is directly tied to the substrate and the process itself.

The Substrate is Foundational

A PVD coating enhances the properties of the substrate; it does not replace them. The final hardness and durability depend heavily on the underlying material.

Applying a hard coating to a soft base material will not make the entire part indestructible. The surface may resist scratches, but a heavy impact can still dent the softer substrate beneath it.

It Is a Thin Film

The thin nature of PVD is an advantage for preserving detail, but it also means it is not a "filler." It will not hide underlying surface imperfections like scratches or tool marks.

For a flawless finish, the substrate must be polished and prepared to the desired standard before the coating is applied.

PVD is a Line-of-Sight Process

In the PVD process, the coating material travels in a straight line from the source to the substrate.

This means that complex internal geometries or hidden surfaces can be difficult to coat uniformly without sophisticated racking and part rotation within the vacuum chamber.

Is PVD the Right Choice for Your Application?

Choosing PVD depends entirely on your primary goal. It is a premium process that offers a powerful combination of functional and aesthetic benefits.

- If your primary focus is mechanical performance: PVD is a superior choice for increasing the lifespan and efficiency of cutting tools, molds, and high-wear components.

- If your primary focus is decorative durability: Use PVD for watches, architectural hardware, and premium consumer goods where a long-lasting, vibrant, and corrosion-resistant finish is required.

- If your primary focus is material compatibility: PVD's low-temperature process makes it one of the best options for applying a hard, durable coating to heat-sensitive alloys and materials.

Ultimately, PVD is an investment in the long-term integrity and value of your product.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| Superior Hardness | Increases wear resistance and lifespan | Cutting tools, engine parts |

| Exceptional Adhesion | Molecular bond prevents chipping/flaking | Durable components, blades |

| Corrosion Resistance | Protects against salt, chemicals, oxidation | Marine hardware, outdoor fixtures |

| Low-Temperature Process | Safe for heat-sensitive materials | Precision instruments, alloys |

| Wide Color Range | Premium decorative finishes (gold, black, etc.) | Watches, jewelry, architectural hardware |

Ready to enhance your product's performance and appearance with PVD coating? At KINTEK, we specialize in advanced lab equipment and consumables for precise surface treatments. Whether you're developing cutting tools, high-wear components, or premium decorative products, our solutions deliver unmatched durability and finish quality. Contact us today to discuss how PVD coating can add value to your laboratory or manufacturing process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating