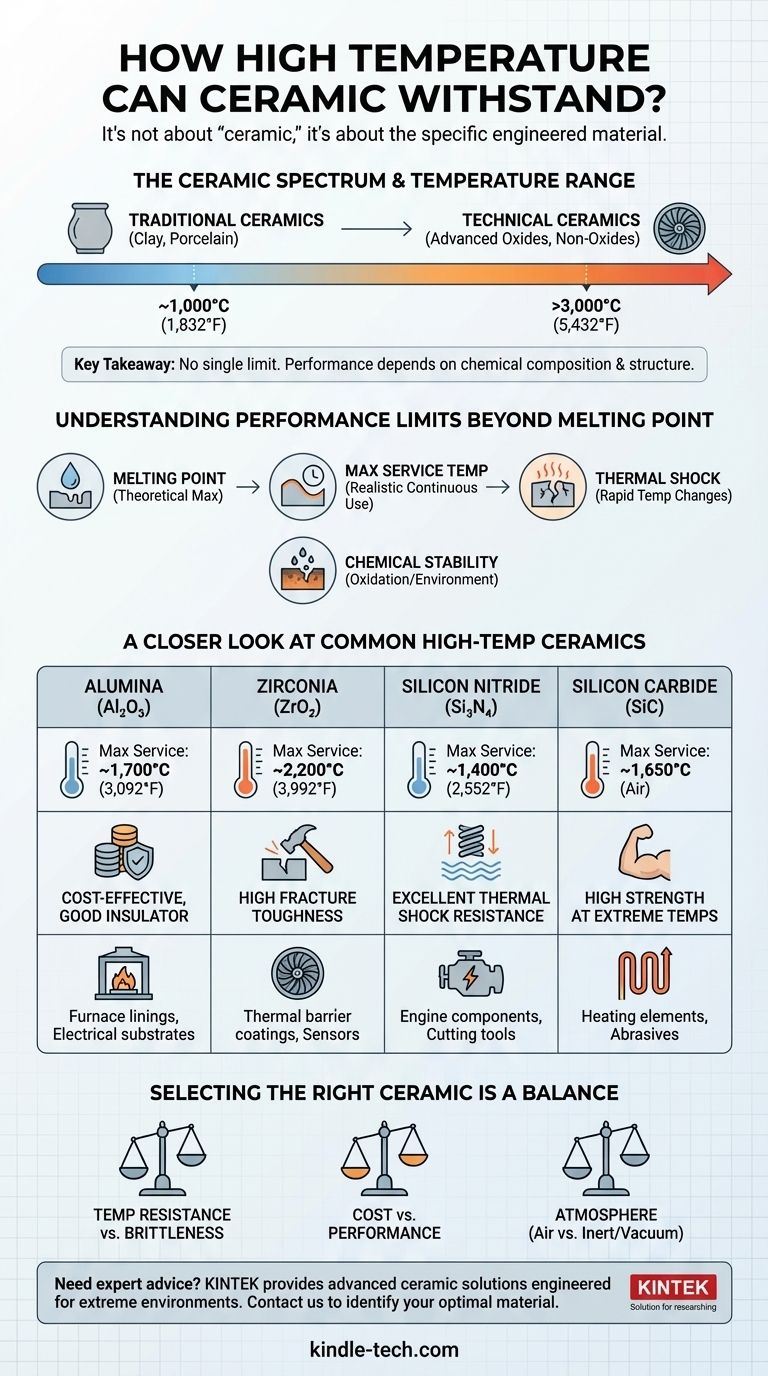

The temperature a ceramic can withstand varies dramatically, ranging from around 1,000°C (1,832°F) for common porcelain to well over 3,000°C (5,432°F) for specialized technical ceramics. This vast range exists because "ceramic" is a broad category of materials, each with a unique chemical composition and crystalline structure that dictates its performance under extreme heat.

The critical takeaway is that there is no single temperature limit for all ceramics. The true question is not "how hot can ceramic get?" but rather "which specific ceramic is engineered to survive the thermal, chemical, and mechanical stresses of my application?"

Why "Ceramic" is Too Broad a Term

To select the right material, you must first understand that the familiar ceramics of daily life are fundamentally different from the advanced materials used in industry.

The Difference Between Traditional and Technical Ceramics

Traditional ceramics, like pottery, brick, and porcelain, are typically clay-based. While heat-resistant compared to metals or plastics, their temperature limits and mechanical properties are modest.

Technical ceramics, also known as advanced or engineering ceramics, are highly purified materials (like oxides, carbides, and nitrides) with superior properties. These are the materials used for applications like furnace linings, turbine blades, and electronic substrates.

The Major Families of Technical Ceramics

Technical ceramics are best understood by their chemical makeup, which directly influences their thermal performance.

- Oxide Ceramics: These are compounds of metal and oxygen. They are generally stable in air at high temperatures and are excellent thermal and electrical insulators. Common examples include Alumina (Al₂O₃) and Zirconia (ZrO₂).

- Non-Oxide Ceramics: This group includes carbides, nitrides, and borides. They often offer higher temperature limits and superior thermal shock resistance compared to oxides, but can be susceptible to oxidation if not used in a controlled atmosphere. Key examples are Silicon Carbide (SiC) and Silicon Nitride (Si₃N₄).

Understanding Performance Limits Beyond Melting Point

A material's melting point is only the theoretical maximum. In practice, a ceramic's useful service temperature is determined by several other critical factors.

The Role of Melting Temperature

The melting point sets the absolute upper boundary, but ceramics typically become unusable far below this temperature due to softening and loss of structural integrity. A material's maximum service temperature is the realistic limit for continuous use.

The Critical Factor: Thermal Shock Resistance

Thermal shock is the tendency for a material to crack when subjected to rapid temperature changes. Ceramics are brittle and generally have poor thermal shock resistance because they don't expand or contract uniformly.

This property, not melting point, is often the primary reason for failure in applications with fluctuating temperatures. Materials like Silicon Nitride are specifically engineered to have excellent thermal shock resistance.

Chemical Stability at High Temperatures

At extreme temperatures, the surrounding atmosphere can degrade a ceramic. For example, non-oxide ceramics like Silicon Carbide can begin to oxidize (react with oxygen) in air, which can compromise their structure long before they reach their melting point. The choice of ceramic must account for the chemical environment it will operate in.

A Closer Look at Common High-Temperature Ceramics

Here is a practical breakdown of widely used technical ceramics and their typical performance limits.

Alumina (Aluminum Oxide)

Alumina is the most common and cost-effective technical ceramic. It serves as the workhorse for high-temperature applications due to its excellent stability and insulating properties.

- Maximum Service Temperature: ~1,700°C (3,092°F)

Zirconia (Zirconium Dioxide)

Often stabilized with yttria (YSZ), Zirconia has a higher service temperature than Alumina and exhibits superior fracture toughness. It is often used as a thermal barrier coating on metal components, like jet engine blades.

- Maximum Service Temperature: ~2,200°C (3,992°F)

Silicon Nitride (Si₃N₄)

The standout feature of Silicon Nitride is its exceptional thermal shock resistance combined with high strength. This makes it ideal for dynamic, high-temperature applications like automotive engine components.

- Maximum Service Temperature: ~1,400°C (2,552°F), limited by oxidation in air.

Silicon Carbide (SiC)

Silicon Carbide maintains its strength at very high temperatures, making it one of the best materials for extreme heat applications. It does not melt at normal pressures but instead sublimates (turns directly to gas) at around 2,700°C.

- Maximum Service Temperature: Up to 1,650°C (3,002°F) in air; can be much higher in inert environments.

Understanding the Trade-offs

Choosing a ceramic is an exercise in balancing competing properties. No single material is perfect for every situation.

Temperature Resistance vs. Brittleness

Generally, materials with higher temperature ceilings can also be more brittle and susceptible to catastrophic failure without warning. Zirconia is a notable exception, offering improved toughness.

Cost vs. Performance

There is a direct correlation between performance and cost. Alumina is relatively inexpensive, while high-purity non-oxide ceramics like Silicon Nitride and Silicon Carbide are significantly more costly to produce.

Atmosphere and Environmental Impact

The performance ratings listed above are often for operation in air. If your application involves a vacuum or an inert (non-reactive) gas, the maximum service temperature for non-oxide ceramics can increase substantially, as the risk of oxidation is removed.

Selecting the Right Ceramic for Your Application

Your choice must be driven by a clear understanding of your primary operational goal.

- If your primary focus is cost-effective structural components or insulation up to 1700°C: Alumina is the default starting point and industry standard.

- If your primary focus is thermal insulation with high fracture toughness: Zirconia is an excellent candidate, especially for thermal barrier coatings.

- If your primary focus is superior thermal shock resistance in a dynamic environment: Silicon Nitride is specifically engineered for this challenge.

- If your primary focus is maximum strength retention at extreme temperatures (above 1400°C): Silicon Carbide is a leading choice, provided you account for the operating atmosphere.

By defining your application's specific demands, you can select a ceramic engineered to succeed in its intended environment.

Summary Table:

| Ceramic Type | Key Feature | Max Service Temp (°C) | Common Applications |

|---|---|---|---|

| Alumina (Al₂O₃) | Cost-effective, good insulator | ~1,700°C | Furnace linings, electrical substrates |

| Zirconia (ZrO₂) | High fracture toughness | ~2,200°C | Thermal barrier coatings, sensors |

| Silicon Nitride (Si₃N₄) | Excellent thermal shock resistance | ~1,400°C | Engine components, cutting tools |

| Silicon Carbide (SiC) | High strength at extreme temperatures | Up to 1,650°C (air) | Heating elements, abrasives |

Struggling to select the right ceramic for your high-temperature process? The experts at KINTEK understand that every application has unique thermal, chemical, and mechanical demands. We specialize in providing advanced lab equipment and ceramic consumables engineered for extreme environments. Whether you need durable furnace linings, high-performance heating elements, or custom ceramic components, our team can help you identify the optimal material solution.

Contact KINTEK today for a personalized consultation. Let us help you achieve superior performance and longevity in your high-temperature applications.

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What is refractory ceramic? The Engineered Barrier for Extreme Heat and Harsh Environments

- What is sintered ceramic? A Durable, Non-Porous Material for Modern Surfaces

- Is there anything better than a ceramic coating? Yes, for ultimate paint protection, combine PPF & ceramic coatings.

- How are ceramic rods made? From Powder to Precision for High-Temp Applications

- What is the effect of heating rate on sintering? Achieve Uniform Density and Avoid Defects

- Does sintering increase grain size? Mastering the Trade-Off for Material Properties

- What is microwave sintering? Unlock Faster, More Efficient Material Processing

- Why ceramics can withstand high temperature? Unlock the Secrets of Atomic Structure