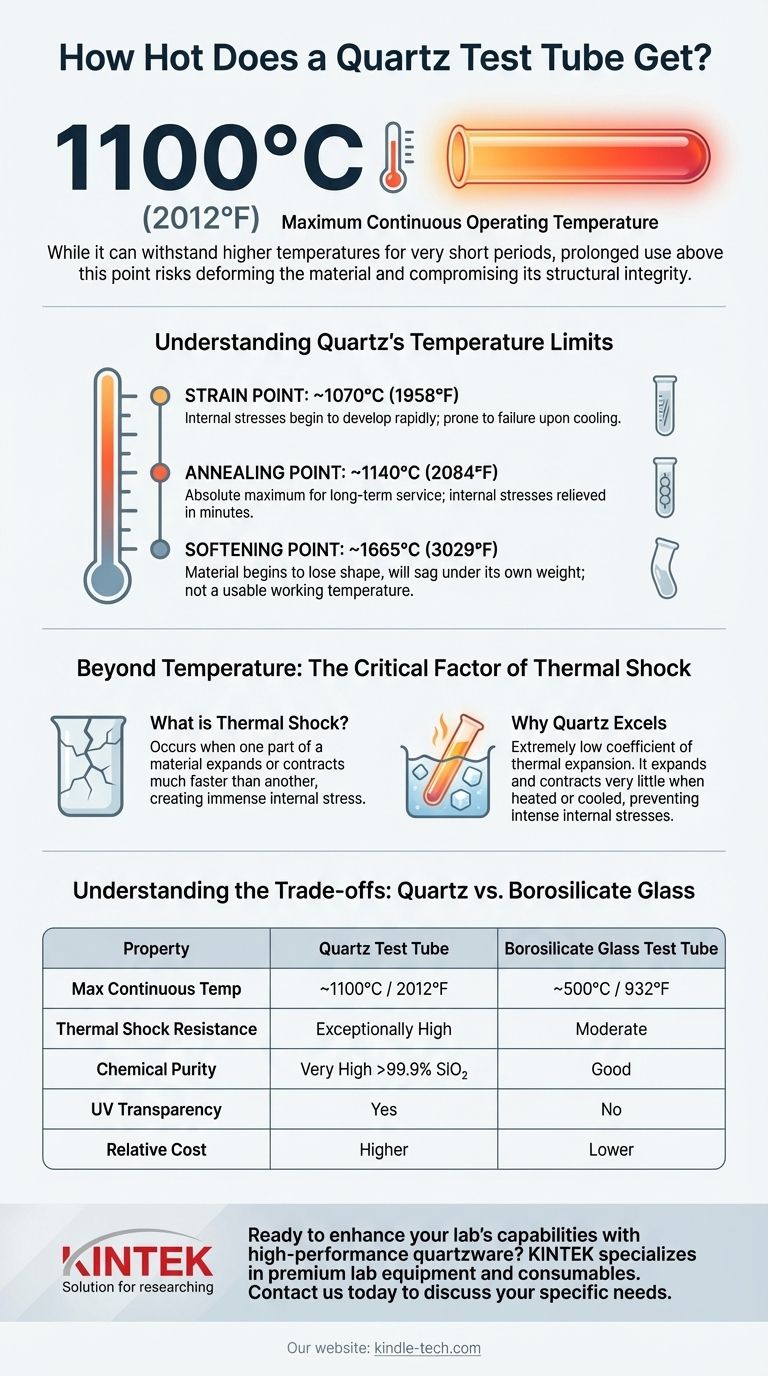

The maximum continuous operating temperature for a fused quartz test tube is approximately 1100°C (2012°F). While it can withstand higher temperatures for very short periods, prolonged use above this point risks deforming the material and compromising its structural integrity. Understanding the specific temperature thresholds is critical for both safety and experimental success.

The question isn't just about a single maximum temperature. The true value of quartz lies in its exceptional thermal stability and resistance to thermal shock, allowing it to handle extreme heat and rapid temperature changes that would shatter conventional glass.

Understanding Quartz's Temperature Limits

Unlike a substance with a sharp melting point, glass-like materials have several key temperature thresholds that define their practical working range. For fused quartz (a very pure form of glass made from silica), these points are significantly higher than for standard borosilicate glass (like Pyrex).

The Strain Point: ~1070°C (1958°F)

This is the temperature at which internal stresses begin to develop rapidly. Operating near or above this point for extended periods can make the material brittle and prone to failure upon cooling.

The Annealing Point: ~1140°C (2084°F)

At this temperature, any internal stress within the quartz can be relieved in a matter of minutes. This is generally considered the absolute maximum for long-term service. Pushing beyond this point will lead to deformation.

The Softening Point: ~1665°C (3029°F)

This is the temperature at which the quartz begins to lose its shape and will sag under its own weight. It is not a usable working temperature for a test tube but is a critical limit for the material itself. It is far from being a liquid but is no longer a rigid solid.

Beyond Temperature: The Critical Factor of Thermal Shock

A material's maximum temperature is only half the story. The real-world performance of labware often depends on its ability to handle rapid temperature changes without cracking.

What is Thermal Shock?

Thermal shock occurs when one part of a material expands or contracts much faster than another, creating immense internal stress. A thick, cold glass tumbler cracking when filled with boiling water is a classic example.

Why Quartz Excels

Quartz has an extremely low coefficient of thermal expansion. This means it expands and contracts very little when heated or cooled. Because it doesn't change size dramatically, intense internal stresses don't build up during rapid temperature shifts.

A Clear Demonstration

This property is why you can heat a quartz test tube until it glows red-hot and then plunge it directly into cold water without it shattering. Performing the same test with a borosilicate (Pyrex) tube would cause it to break instantly.

Understanding the Trade-offs: Quartz vs. Borosilicate Glass

Choosing the right material requires understanding the key differences between quartz and the more common borosilicate glass used for most lab beakers and flasks.

Temperature Resistance

Quartz is the clear winner, with a maximum continuous use temperature of around 1100°C. Borosilicate glass should not be used for continuous service above ~500°C (932°F).

Thermal Shock Resistance

Quartz is vastly superior due to its near-zero thermal expansion. It can handle radical and immediate temperature changes that are impossible for borosilicate glass.

Chemical Purity and Transparency

Fused quartz is exceptionally pure, often greater than 99.9% SiO₂. This prevents sample contamination and also allows it to be transparent to ultraviolet (UV) light, a property borosilicate glass lacks.

The Cost Factor

This is the most significant trade-off. Quartzware is substantially more expensive than its borosilicate equivalent. Its use is typically reserved for applications where its unique thermal or optical properties are essential.

Making the Right Choice for Your Application

Selecting the correct test tube prevents costly equipment failure and ensures the safety of your experiment.

- If your primary focus is working at temperatures between 500°C and 1100°C: Quartz is your only safe and reliable option.

- If your primary focus is applications involving rapid heating and cooling cycles: Quartz's resistance to thermal shock is essential to prevent fracture.

- If your primary focus is high-purity chemical work or applications requiring UV transparency: Fused quartz provides the purity and optical clarity that other materials cannot.

- If your primary focus is general lab heating below 500°C without extreme thermal shock: Borosilicate glass is the most practical and cost-effective choice.

Ultimately, choosing the right material is about matching its specific properties to the demands of your work.

Summary Table:

| Property | Quartz Test Tube | Borosilicate Glass Test Tube |

|---|---|---|

| Max Continuous Temp | ~1100°C (2012°F) | ~500°C (932°F) |

| Thermal Shock Resistance | Exceptionally High (can go from red-hot to cold water) | Moderate |

| Chemical Purity | Very High (>99.9% SiO₂) | Good |

| UV Transparency | Yes | No |

| Relative Cost | Higher | Lower |

Ready to enhance your lab's capabilities with high-performance quartzware?

KINTEK specializes in premium lab equipment and consumables, including high-purity fused quartz test tubes designed for extreme temperatures and thermal shock resistance. Our products ensure the safety and success of your most demanding experiments.

Contact us today via our [#ContactForm] to discuss your specific needs and discover how KINTEK's solutions can bring reliability and precision to your laboratory.

Visual Guide

Related Products

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

People Also Ask

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas

- What are the advantages and disadvantages of thermal cracking? A Guide to Foundational Refining

- Why is a vertical furnace filled with an inert gas like argon necessary? Ensure Purity in Chalcogenide Production

- What is the purpose of using a tube furnace in the calcination process of NCM811 cathode materials? | KINTEK Solution

- What is the function of a tube atmosphere furnace in Li2MnSiO4 synthesis? Achieve High-Purity Battery Materials

- Why is a controlled atmosphere tube furnace required for palladium nanoparticle reduction? Achieve Catalyst Precision

- Why use a tube furnace? Achieve Superior Temperature Uniformity and Atmosphere Control

- How does a quartz tube facilitate fractional condensation in a horizontal tube vacuum gasification furnace? Expert Guide