At its core, Physical Vapor Deposition (PVD) is not a temporary finish but a long-term surface modification. While there is no single answer for how long it lasts, a well-applied PVD coating on a quality product can last for many years, often decades, and in low-wear applications, it can be considered permanent. Its longevity far surpasses traditional plating methods due to its exceptional hardness and resistance to wear.

The lifespan of a PVD coating isn't measured in a fixed number of years, but by its incredible resistance to failure. Its durability comes from a molecular bonding process that creates a surface far harder and more resilient than the base material itself.

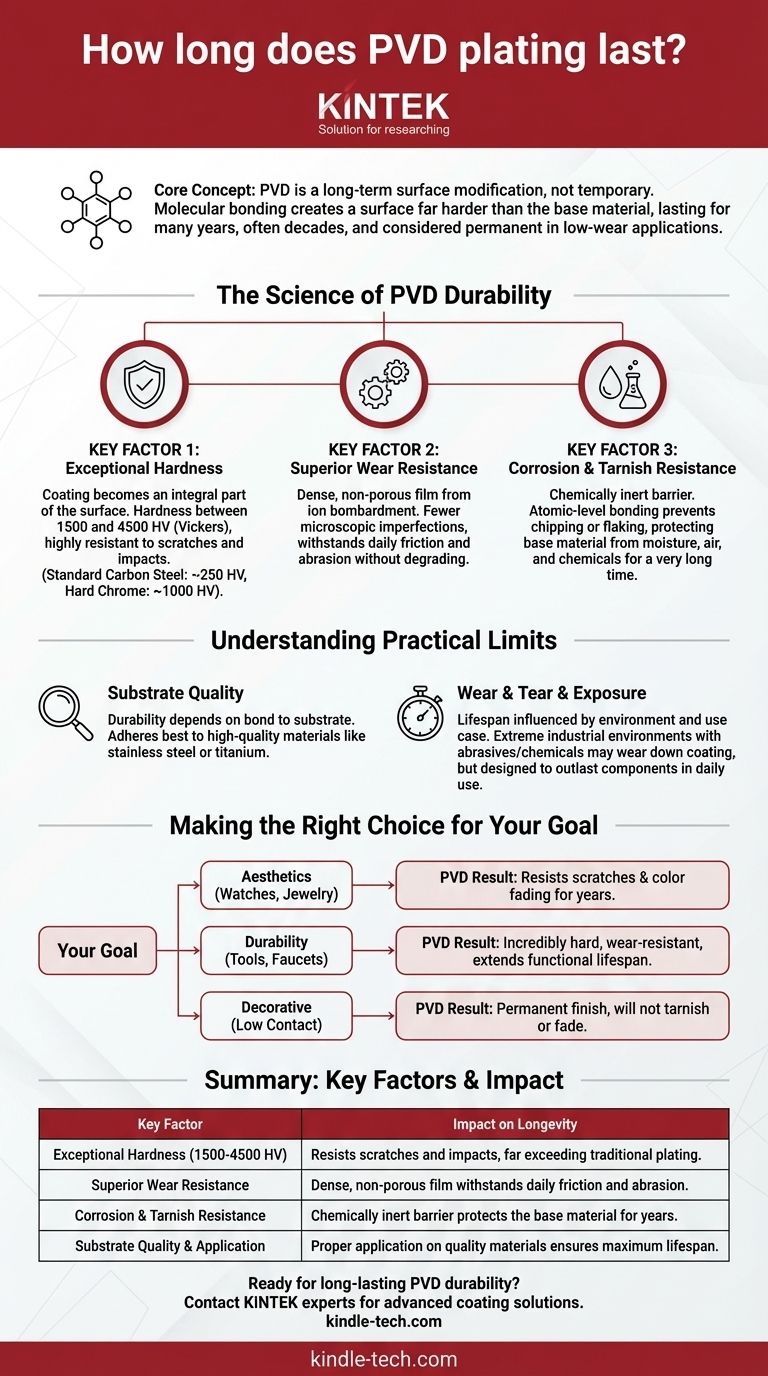

The Science of PVD Durability

To understand why PVD coatings are so long-lasting, you must first understand the process. It's fundamentally different from traditional painting or electroplating, which simply lay a layer of material on top of a surface.

What is PVD Plating?

PVD, or Physical Vapor Deposition, is a process conducted in a high-tech vacuum chamber. Think of it as a form of molecular spray-painting.

Solid coating material is vaporized into a plasma of atoms or ions. These particles are then bonded directly to the part's surface, creating an extremely thin yet incredibly tough and dense layer.

Key Factor 1: Exceptional Hardness

The primary reason for PVD's longevity is its hardness. The coating becomes an integral part of the surface, not just a layer on top of it.

PVD coatings can achieve a hardness between 1500 and 4500 HV (Vickers). For context, standard carbon steels are only around 250 HV, and even hard chrome plating typically maxes out around 1000 HV. This makes PVD surfaces highly resistant to scratches and impacts.

Key Factor 2: Superior Wear Resistance

Hardness contributes to wear resistance, but the PVD process itself is the real hero. The ion bombardment during the application creates a very dense and non-porous film.

This density means there are fewer microscopic imperfections where wear and corrosion can begin. The result is a finish that can withstand daily friction and abrasion without degrading.

Key Factor 3: Corrosion and Tarnish Resistance

The PVD process creates a chemically inert barrier on the surface of the product. This robust layer seals the base material from exposure to moisture, air, and chemicals.

Because the coating is bonded at an atomic level, it is not susceptible to chipping or flaking like paint or traditional plating. This ensures the underlying material remains protected from corrosion and tarnish for a very long time.

Understanding the Practical Limits

While remarkably durable, no coating is indestructible. The lifespan of a PVD finish is ultimately influenced by its environment and the quality of its application.

The Impact of Substrate Quality

The PVD coating is only as durable as its bond to the material underneath, known as the substrate. The coating adheres best to high-quality materials like stainless steel or titanium. A poor-quality or improperly prepared substrate can compromise the coating's longevity.

The Influence of Wear and Tear

The specific use case is the most significant variable. A PVD-coated watch worn daily will be subjected to more friction and impacts than a decorative light fixture.

Even so, PVD-coated items intended for daily use, like watch bands or high-end faucets, are engineered to resist this wear for many years, often outlasting the product's mechanical components.

Exposure to Abrasives and Chemicals

While resistant to most chemicals, constant exposure to harsh or abrasive substances can eventually wear down a PVD coating. This is typically only a concern in extreme industrial environments, not household use.

Making the Right Choice for Your Goal

PVD is often the superior choice, but understanding your specific goal is key to appreciating its value.

- If your primary focus is aesthetics for daily-use items (watches, jewelry): PVD offers a finish that will resist scratches and color fading for years, far longer than any traditional plating.

- If your primary focus is durability for functional items (tools, faucets): PVD provides an incredibly hard, wear-resistant surface that protects against corrosion and extends the product's functional lifespan significantly.

- If your primary focus is a "set and forget" decorative finish: For items with low physical contact, a PVD coating can be considered a permanent finish that will not tarnish or fade over time.

Ultimately, choosing PVD is an investment in a finish that is designed to last the lifetime of the product itself.

Summary Table:

| Key Factor | Impact on Longevity |

|---|---|

| Exceptional Hardness (1500-4500 HV) | Resists scratches and impacts, far exceeding traditional plating. |

| Superior Wear Resistance | Dense, non-porous film withstands daily friction and abrasion. |

| Corrosion & Tarnish Resistance | Chemically inert barrier protects the base material for years. |

| Substrate Quality & Application | Proper application on quality materials (e.g., stainless steel) ensures maximum lifespan. |

Ready to integrate long-lasting PVD durability into your products?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory equipment, tools, and high-wear components. Our coatings are engineered to provide decades of reliable performance, protecting your products from wear, corrosion, and tarnish.

Contact our experts today to discuss how our PVD technology can enhance the longevity and value of your products.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding