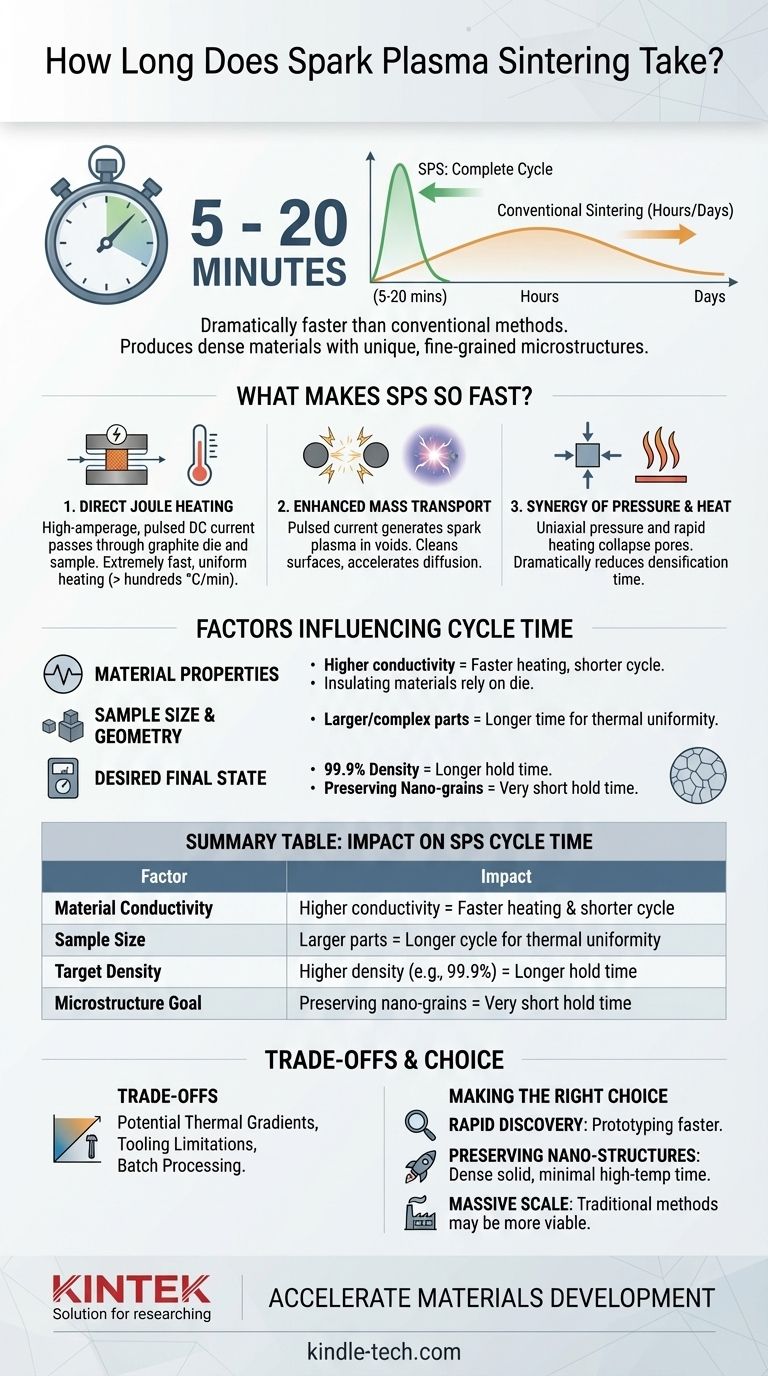

In most cases, a complete spark plasma sintering (SPS) cycle takes between 5 and 20 minutes. This is dramatically faster than conventional sintering techniques, such as hot pressing or furnace sintering, which can often require many hours or even days to complete a full thermal cycle.

The defining advantage of Spark Plasma Sintering is not just its speed, but how that speed fundamentally alters the process. By minimizing the time a material spends at high temperatures, SPS can produce dense materials with unique, fine-grained microstructures that are often impossible to achieve with slower methods.

What Makes Spark Plasma Sintering So Fast?

The exceptional speed of SPS is not an incremental improvement; it results from a fundamentally different method of delivering energy to the material. Several mechanisms work in concert to achieve rapid densification.

Direct Joule Heating

Unlike a conventional furnace that heats a chamber radiatively, SPS passes a high-amperage, pulsed DC current directly through the graphite die and, often, the conductive sample itself.

This process, known as Joule heating, is incredibly efficient and generates heat internally. This leads to the extremely fast and uniform heating rates mentioned in research, often exceeding several hundred degrees Celsius per minute.

Enhanced Mass Transport

The pulsed electrical current is believed to do more than just generate heat. It is theorized to generate spark plasma in the voids between powder particles.

This plasma cleans particle surfaces by stripping away contaminants and oxides. This pristine surface condition, combined with the electric field, significantly accelerates diffusion, which is the primary mechanism for bonding particles together and eliminating porosity.

The Synergy of Pressure and Heat

SPS applies uniaxial pressure simultaneously with the rapid heating cycle. This mechanical force complements the thermally-driven diffusion processes.

The pressure physically forces particles closer together, aiding in the collapse of pores and dramatically reducing the time required to achieve a fully dense final part.

Factors That Influence SPS Cycle Time

While "5 to 20 minutes" is a reliable benchmark, the precise duration of an SPS cycle is not a fixed number. It is influenced by several critical factors related to your material and your goals.

Material Properties

The thermal and electrical conductivity of your powder is paramount. A highly conductive material will heat more quickly and uniformly. In contrast, insulating materials (like many ceramics) rely on the graphite die to conduct heat, which can slightly increase the required time.

Sample Size and Geometry

A small, simple cylindrical sample will process much faster than a large or complex-shaped component. Larger parts require more time to ensure thermal uniformity from the core to the surface and also have more thermal mass, lengthening the required cooling time.

Desired Final State

The ultimate goal for the material dictates the process parameters. Achieving 99.9% theoretical density may require a longer hold time at the peak temperature compared to a goal of 95% density.

Furthermore, if the goal is to preserve a nano-grained microstructure, the operator will prioritize an extremely short hold time to prevent grain growth.

Understanding the Trade-offs of Speed

The rapid nature of SPS is its primary strength, but it also introduces considerations that do not exist in slower, conventional processes.

Potential for Thermal Gradients

In very large samples or with extremely high heating rates, a temperature difference can develop between the hotter surface and the cooler core. This requires careful process control and die design to mitigate, ensuring the final part has homogenous properties.

Tooling and Geometry Limitations

SPS relies on graphite tooling (dies and punches) that must withstand intense thermal and mechanical stress. This tooling can be expensive and places practical limits on the size and geometric complexity of parts that can be produced.

Batch Processing Nature

SPS is fundamentally a batch process. One part or a small batch of parts is processed at a time. While each cycle is very fast, this can be a limitation for true mass production when compared to continuous sintering methods used for high-volume manufacturing.

Making the Right Choice for Your Goal

The speed of SPS is a tool. Understanding when to leverage it is key to successful materials development and processing.

- If your primary focus is rapid material discovery and prototyping: SPS is an unparalleled tool, allowing for dozens of experimental iterations in the time it takes to run a single conventional furnace cycle.

- If your primary focus is preserving nano-structures or metastable phases: The ability of SPS to consolidate powders into a dense solid with minimal time at high temperature is its most powerful feature, preventing unwanted grain growth.

- If your primary focus is producing large, simple, non-critical parts at massive scale: The batch nature and tooling costs of SPS may make traditional press-and-sinter or metal injection molding more economically viable.

By understanding the principles behind its speed, you can leverage Spark Plasma Sintering to not just make materials faster, but to create materials that are fundamentally better.

Summary Table:

| Factor | Impact on SPS Cycle Time |

|---|---|

| Material Conductivity | Higher conductivity = faster heating & shorter cycle |

| Sample Size | Larger parts = longer cycle for thermal uniformity |

| Target Density | Higher density (e.g., 99.9%) = longer hold time |

| Microstructure Goal | Preserving nano-grains = very short hold time |

Ready to accelerate your materials development with rapid, high-performance sintering?

KINTEK specializes in advanced lab equipment, including Spark Plasma Sintering solutions, to help you achieve dense materials with fine-grained microstructures in minutes, not days. Our expertise can help you preserve nano-structures, prototype faster, and create superior materials.

Contact our sintering experts today to discuss how SPS can transform your research and production!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What critical processing conditions does a vacuum hot pressing sintering furnace provide for high-density VC/Cu?

- How does external heating in vacuum hot pressing benefit large magnesium components vs SPS? Scaling Your Production

- What are the applications of spark plasma sintering? Fabricate High-Performance Materials with Precision

- What are the uses of spark plasma sintering? Fast, Low-Temp Fabrication of Advanced Materials

- What is the step-by-step process for growing a diamond using the HPHT method? Master Lab-Grown Diamond Synthesis

- What is the difference between conventional and spark sintering? Choose the Right Process for Your Materials

- How does a vacuum hot pressing furnace facilitate the densification of Eu:Y2O3 scintillator ceramics?

- Why is a vacuum hot press furnace preferred for bulk nano-tungsten? Preserving Microstructure via Low-Heat Pressing