There is no single answer to how long calcination takes; the duration is not a fixed value but a result of specific process variables. The time can range from less than an hour in a controlled laboratory setting to over 24 hours in large-scale industrial kilns, depending entirely on the material, temperature, and equipment used.

The duration of calcination is determined by a critical balance: the rate of heat transfer into the material must be sufficient to drive the chemical decomposition, and the rate of mass transfer must allow the resulting gases (like CO₂ or H₂O) to escape efficiently.

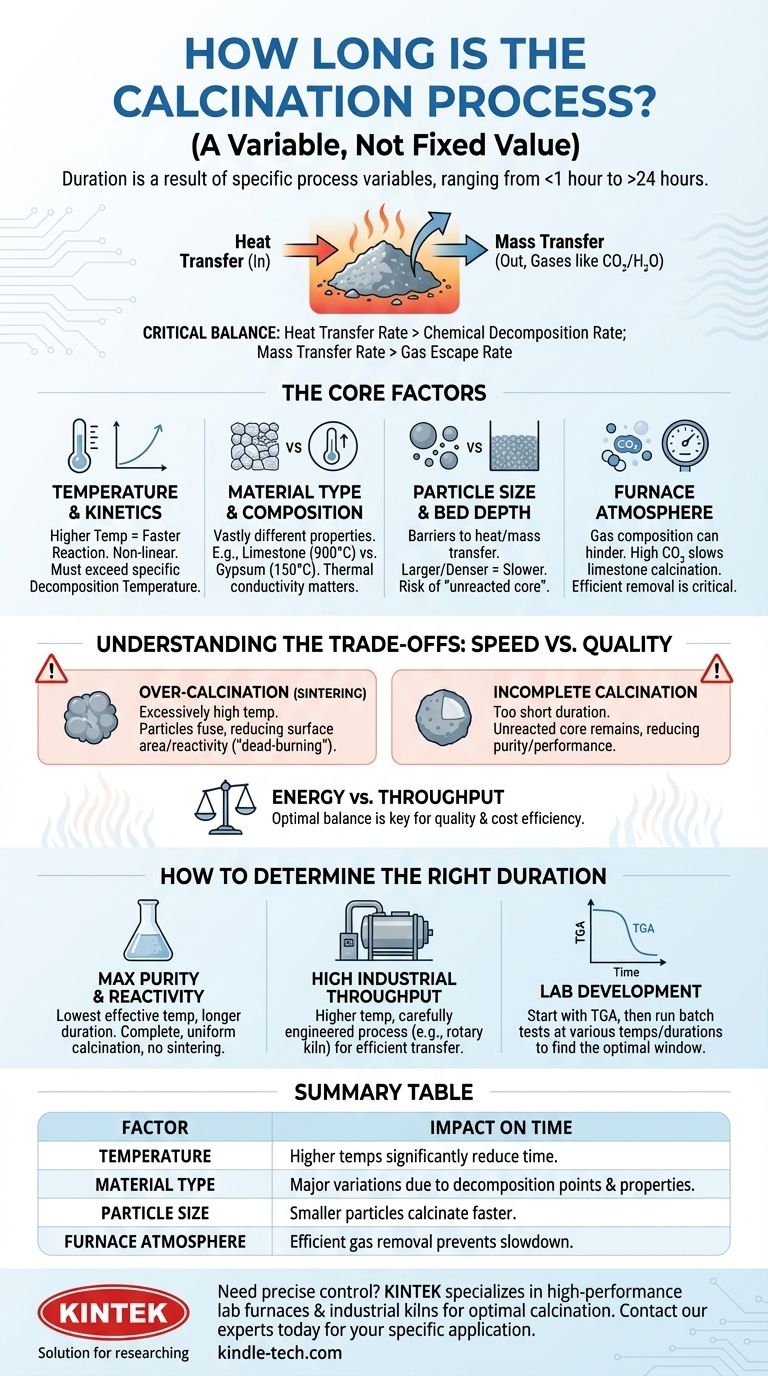

The Core Factors That Dictate Calcination Time

To control the duration of calcination, you must first understand the variables that govern the process. The time required is a direct function of the material's properties and the conditions you create.

The Role of Temperature and Reaction Kinetics

The single most significant factor is temperature. Higher temperatures dramatically increase the rate of the decomposition reaction, reducing the required time.

However, the relationship isn't linear. Every material has a specific decomposition temperature below which calcination will not occur, no matter how long you wait. Exceeding this temperature provides the energy needed to break chemical bonds.

The Impact of Material Type and Composition

Different materials have vastly different thermal properties and decomposition points. For example, the calcination of limestone to produce lime requires much higher temperatures (around 900°C) than the dehydration of gypsum (around 150°C).

The material's thermal conductivity also plays a crucial role. A material that conducts heat poorly will require more time for the core to reach the necessary decomposition temperature.

Why Particle Size and Bed Depth Matter

Calcination is fundamentally a process of heat and mass transfer. Larger particles or a deeper bed of material create significant barriers to both.

Heat must penetrate from the outside in, and gases must escape from the inside out. A large, dense particle can develop an "unreacted core" if the residence time is too short, resulting in incomplete calcination.

The Influence of Furnace Atmosphere

The composition of the gas inside the furnace or kiln can either help or hinder the process.

For example, in limestone calcination, a high partial pressure of carbon dioxide (CO₂) in the furnace atmosphere can slow or even reverse the reaction. Efficiently removing the CO₂ as it's produced is critical for driving the reaction forward and reducing the required time.

Understanding the Trade-offs: Speed vs. Quality

Simply aiming for the shortest possible time can lead to significant problems with product quality and energy efficiency. Understanding the trade-offs is essential for process optimization.

The Risk of Over-calcination (Sintering)

Applying excessively high temperatures to speed up the process can cause sintering, where the material's particles begin to fuse.

This reduces the surface area and reactivity of the final product, a phenomenon known as "dead-burning." A dead-burned lime, for instance, is far less reactive and valuable for many applications.

The Problem of Incomplete Calcination

Conversely, a duration that is too short for the given temperature and particle size will result in an incompletely calcined product.

This leaves an unreacted core in the material, reducing the purity and performance of the final product. It is a common issue when trying to maximize throughput without adjusting other parameters.

Balancing Energy Consumption with Throughput

Shorter calcination times at higher temperatures require significantly more energy. The goal of any industrial process is to find the optimal balance between residence time and temperature that produces the desired quality at the lowest possible energy cost per unit of product.

How to Determine the Right Duration for Your Process

The ideal calcination time is entirely dependent on your specific objective. There is no universally "correct" duration.

- If your primary focus is maximum product reactivity and purity: Use the lowest effective temperature and a longer duration to ensure complete, uniform calcination without sintering.

- If your primary focus is high industrial throughput: You will likely use a higher temperature and must carefully engineer the process (e.g., using a rotary kiln) to ensure efficient heat and mass transfer in a shorter time.

- If you are developing a new process in the lab: Start with thermogravimetric analysis (TGA) to understand the material's decomposition profile, then run batch tests at various temperatures and durations to map out the optimal processing window.

Ultimately, optimizing calcination time is about precisely controlling the interplay between temperature, material properties, and equipment design to achieve your desired outcome.

Summary Table:

| Factor | Impact on Calcination Time |

|---|---|

| Temperature | Higher temperatures significantly reduce time. |

| Material Type | Different decomposition points and thermal properties cause major variations. |

| Particle Size | Smaller particles calcinate faster due to better heat and mass transfer. |

| Furnace Atmosphere | Efficient gas removal is critical to prevent reaction slowdown. |

Need to precisely control your calcination process? KINTEK specializes in high-performance lab furnaces and industrial kilns designed for optimal heat transfer and process control. Whether you're developing a new material in the lab or scaling up production, our equipment helps you achieve complete calcination with maximum efficiency and product quality. Contact our experts today to discuss your specific application and find the perfect solution.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the effect of pyrolysis temperature on biochar properties? Mastering the Yield vs. Quality Trade-off

- What are the different types of bed motion in a rotary kiln? Optimize Mixing and Heat Transfer Efficiency

- What are the parameters of a rotary kiln? Mastering Control for Optimal Process Results

- What are the operational conditions of pyrolysis? Master Heat, Reactor, and Feedstock for Optimal Results

- What is the difference between microwave pyrolysis and conventional pyrolysis? Choose the Right Heating Method for Your Process

- Is rotary kiln a furnace? Discover the Key Differences for Industrial Processing

- What is the bio-oil yield in fast pyrolysis? High Yield, But Quality is Key

- Why are there chains inside a rotary kiln? Boost Efficiency & Control with Internal Heat Exchange