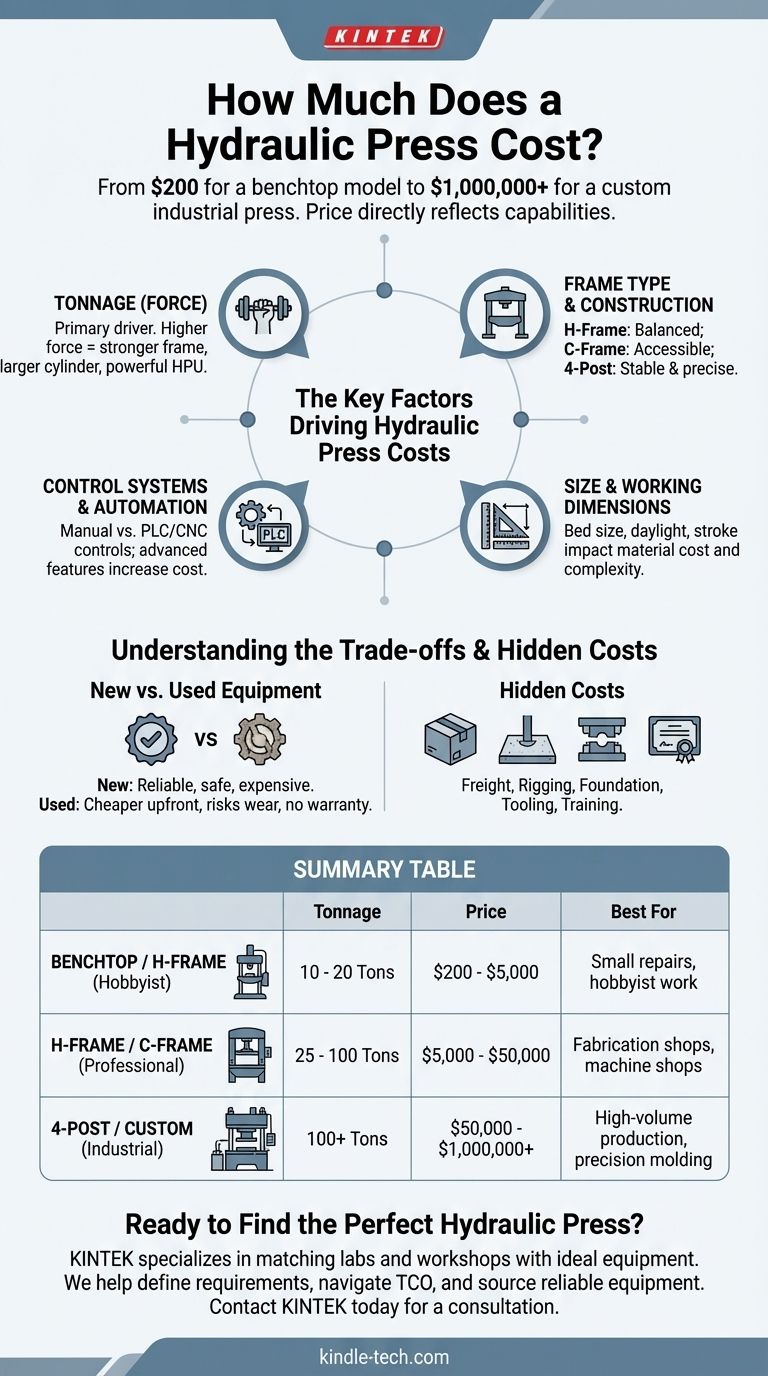

The cost of a hydraulic press spans an enormous range, from as little as $200 for a small benchtop model to well over $1,000,000 for a massive, custom industrial press. This vast difference is not arbitrary; it directly reflects the machine's force, size, construction, and control systems, which are all dictated by its intended application.

The final price of a hydraulic press is not a single number but a direct reflection of its capabilities. The cost is driven primarily by its tonnage (force), frame type, size, and level of control, meaning the most critical step is to precisely define your application before you begin your search.

The Key Factors Driving Hydraulic Press Costs

To understand the price, you must first understand the core components and specifications that determine a press's value and function. The cost scales directly with capability.

Tonnage: The Primary Cost Driver

The single most significant factor in a hydraulic press's cost is its tonnage, or the maximum force it can exert.

Higher tonnage requires a much stronger, heavier frame to withstand the force, a larger hydraulic cylinder to generate it, and a more powerful hydraulic power unit (HPU) to drive it. A 50-ton press can easily be five to ten times more expensive than a 10-ton press of a similar design.

Frame Type and Construction

The physical design of the press is fundamental to its function and cost.

- H-Frame: The most common design for general workshop use. It offers a good balance of strength and accessibility at a moderate price point.

- C-Frame (or Gap Frame): Offers access to the work area from three sides, which is ideal for assembly or processes requiring easy part manipulation. This design is often more complex to engineer for high tonnage, which can increase its cost.

- 4-Post: Provides exceptional stability and uniform pressure across the entire work surface. This design is favored for molding, trimming, and precision applications, and its robust construction typically places it at a higher price point.

Size and Working Dimensions

The physical space available for your workpiece directly impacts material cost and engineering complexity.

Key dimensions include the bed size (the working surface area), the daylight (the maximum vertical space for tooling), and the stroke (the distance the ram can travel). Larger dimensions require more steel and more robust construction, increasing the price.

The Hydraulic Power Unit (HPU)

The system that generates the force has a major impact on both performance and cost.

A simple manual hand pump is the cheapest option, found on small shop presses. An electric-powered HPU is standard on most industrial equipment, offering faster cycle times and consistent pressure. The speed of the press, measured in inches per minute (IPM), and the complexity of its hydraulic circuit add significant cost.

Control Systems and Automation

The level of precision and automation is a major price differentiator.

A basic press uses simple manual lever controls. Advanced presses incorporate Programmable Logic Controllers (PLCs) or CNC controls for precise, repeatable control over speed, pressure, and position. Features like pressure transducers, linear encoders, and safety systems like light curtains dramatically increase the cost but are essential for production environments.

Understanding the Trade-offs and Hidden Costs

The sticker price is only the beginning of the story. A savvy buyer considers the total cost of ownership and potential pitfalls.

New vs. Used Equipment

A used press can offer significant upfront savings. However, this comes with risks, including component wear, a lack of warranty, and potentially outdated safety features. A new press provides reliability and modern safety compliance at a higher initial cost.

Brand Reputation and Support

Well-established manufacturers often command a higher price. This premium pays for superior engineering, higher-quality materials, better reliability, and access to technical support and replacement parts. A cheaper, unsupported press can become a significant liability if it fails.

Beyond the Sticker Price

Several additional costs must be factored into your budget. These include:

- Freight and Rigging: Large presses are heavy and require specialized shipping and installation.

- Foundation: Heavy, high-tonnage presses may require a reinforced concrete foundation.

- Tooling and Dies: The press is only one part of the system; the cost of custom dies can be substantial.

- Training: Complex PLC-controlled presses require operator training to be used effectively and safely.

Making the Right Choice for Your Goal

To select the right press, align your budget with your primary operational need. Your application, not a generic price list, should guide your decision.

- If your primary focus is hobbyist work or small repairs: A simple, low-tonnage (10-20 ton) benchtop or H-frame shop press is the most cost-effective solution.

- If your primary focus is a professional fabrication or machine shop: Invest in a versatile H-frame press (25-100 tons) with an electric pump for a balance of capability and efficiency.

- If your primary focus is high-volume industrial production: The higher cost of a 4-post or custom press with PLC controls is justified by its precision, repeatability, and automation capabilities.

Ultimately, a clear definition of your task is the most valuable tool for controlling costs and ensuring a successful investment.

Summary Table:

| Press Type | Typical Tonnage | Estimated Price Range | Best For |

|---|---|---|---|

| Benchtop / H-Frame (Hobbyist) | 10 - 20 Tons | $200 - $5,000 | Small repairs, hobbyist work |

| H-Frame / C-Frame (Professional) | 25 - 100 Tons | $5,000 - $50,000 | Fabrication shops, machine shops |

| 4-Post / Custom (Industrial) | 100+ Tons | $50,000 - $1,000,000+ | High-volume production, precision molding |

Ready to Find the Perfect Hydraulic Press for Your Needs?

Choosing the right hydraulic press is a critical investment in your workshop's efficiency and capability. The team at KINTEK specializes in matching labs and workshops with the ideal equipment for their specific applications, from benchtop models to high-tonnage industrial systems.

We provide expert guidance to help you:

- Define your exact requirements for tonnage, frame type, and control systems.

- Navigate the total cost of ownership, including tooling, installation, and training.

- Source reliable, high-performance equipment that fits your budget and operational goals.

Don't leave your investment to chance. Contact KINTEL today for a personalized consultation and let our expertise in lab and workshop equipment work for you!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries

- Why is a laboratory precision hot press necessary for processing high-performance composite solid-state electrolyte membranes?

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- How does a laboratory hot press improve the microscopic structure of polymer-ceramic composite cathodes? | KINTEK

- What are the advantages of hot pressing for PEO electrolytes? Achieve superior density and solvent-free performance.