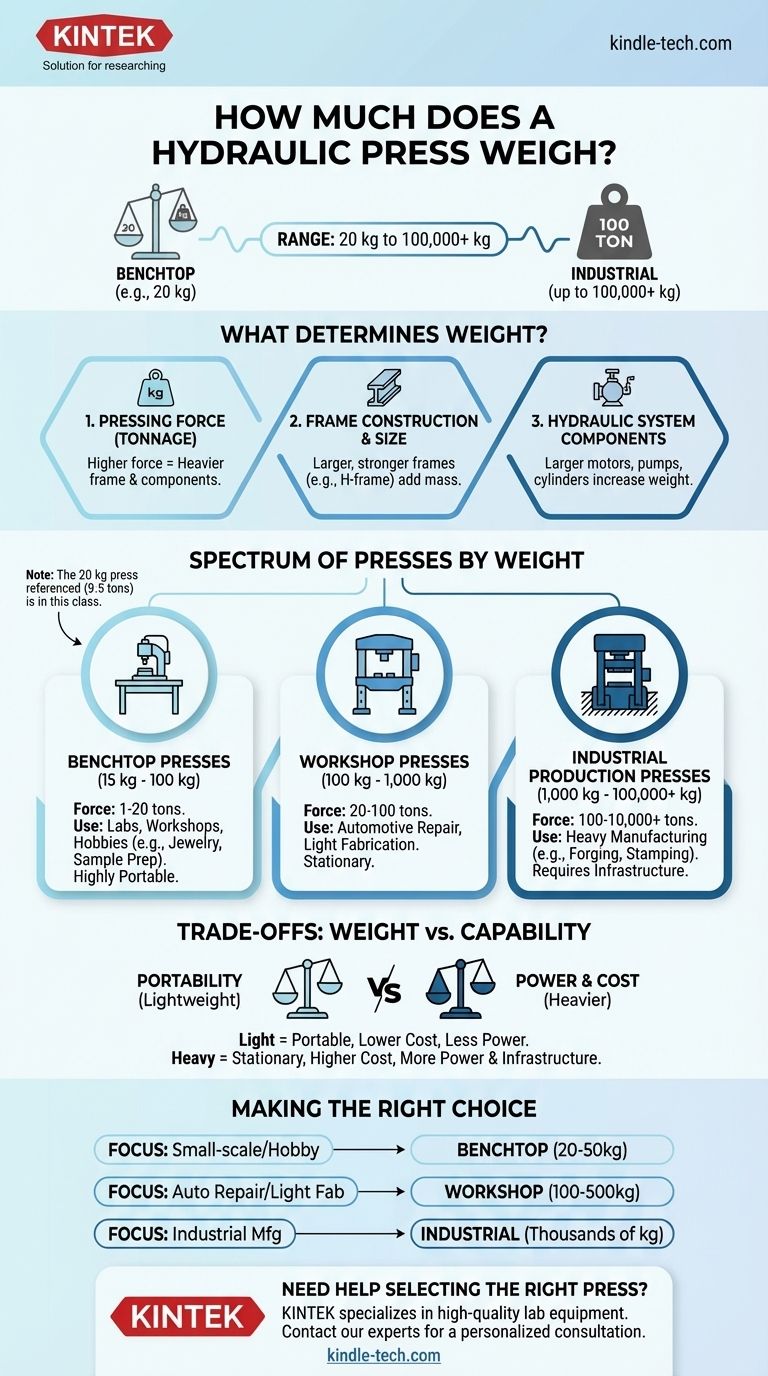

A specific benchtop hydraulic press can weigh 20 kg (approximately 44 lbs). However, this figure represents only one very small type of press. The weight of a hydraulic press varies dramatically based on its size, construction, and the force it is designed to exert, spanning a range from small workshop units to massive industrial machines weighing many tons.

The weight of a hydraulic press is not a single number but a direct reflection of its power and purpose. It is fundamentally tied to the machine's pressing force (tonnage) and physical size, ranging from portable 20 kg models to industrial giants that weigh tens of thousands of kilograms.

What Determines a Hydraulic Press's Weight?

The weight of a press is a direct consequence of the engineering required to safely generate and contain immense force. Several key factors contribute to its final mass.

The Role of Pressing Force (Tonnage)

The single biggest factor is the tonnage, or the maximum force the press can apply. Higher forces require a much stronger, more rigid, and therefore heavier frame to prevent bending or catastrophic failure.

The 20 kg press referenced has a recommended maximum power of 9.5 tons. This is a relatively low tonnage, allowing for a lightweight and compact design.

Frame Construction and Size

The physical structure that holds everything together is the frame. Larger frames are needed to accommodate larger workpieces, and this increase in size directly adds to the weight.

Different designs, like H-frame or C-frame presses, distribute forces differently and use varying amounts of steel, impacting the total mass.

Hydraulic System Components

The power unit itself contributes significant weight. This includes the electric motor, the hydraulic pump, the main cylinder, and the reservoir holding the hydraulic fluid.

As tonnage requirements increase, each of these components must be larger and more robust, adding considerable weight to the overall system.

A Spectrum of Presses by Weight

Understanding the typical weight classes helps to contextualize the 20 kg figure and appreciate the vast range of machines available.

Benchtop Presses (15 kg - 100 kg)

This category includes the 20 kg press from the reference. These are small, often manually operated presses designed for workshops, labs, and hobbyists.

Their force is typically in the 1 to 20-ton range, making them suitable for small tasks like pressing bearings, jewelry making, or lab sample preparation.

Workshop Presses (100 kg - 1,000 kg)

These are the common floor-standing H-frame presses found in automotive repair shops and small fabrication facilities. They are much heavier because they are built to handle higher forces (typically 20 to 100 tons) and larger components.

Their weight makes them stationary, requiring a dedicated spot on the workshop floor.

Industrial Production Presses (1,000 kg - 100,000+ kg)

These are massive machines at the heart of heavy manufacturing, used for processes like forging, stamping car body panels, and molding large parts.

Their tonnage can be in the thousands, and their weight is measured in tons. These presses require specialized reinforced concrete foundations for installation.

Understanding the Trade-offs: Weight vs. Capability

The weight of a press is not just a specification; it represents a fundamental trade-off between portability, cost, and power.

Portability vs. Power

A lightweight, 20 kg press offers excellent portability. It can be moved easily and doesn't require a large, dedicated space.

This portability comes at the cost of power. It is physically limited in the force it can generate and the size of the object it can work on. Heavier presses are stationary but provide vastly more power.

Cost and Infrastructure

Weight is often a rough proxy for cost. More steel and larger components mean a higher purchase price.

Furthermore, heavier presses come with significant infrastructure costs. A multi-ton industrial press requires a purpose-built foundation, high-voltage electrical service, and heavy-duty equipment for installation, all of which add to the total expense.

Making the Right Choice for Your Goal

Selecting a press begins with understanding your core task, which will then dictate the necessary tonnage and, consequently, its approximate weight.

- If your primary focus is small-scale projects or hobby work: A lightweight benchtop press (around 20-50 kg) with 1-10 tons of force offers sufficient power without requiring dedicated floor space.

- If your primary focus is automotive repair or light fabrication: A floor-standing workshop press (100-500 kg) with a 20-50 ton capacity is the industry standard.

- If your primary focus is industrial manufacturing: The weight will be a secondary outcome of your required tonnage and bed size, often reaching many thousands of kilograms.

Ultimately, the weight of a hydraulic press is the most direct physical indicator of its power and intended application.

Summary Table:

| Press Type | Typical Weight Range | Typical Force (Tonnage) | Primary Use Case |

|---|---|---|---|

| Benchtop Press | 15 kg - 100 kg | 1 - 20 tons | Labs, workshops, hobbies (e.g., jewelry, sample prep) |

| Workshop Press (H-frame) | 100 kg - 1,000 kg | 20 - 100 tons | Automotive repair, light fabrication |

| Industrial Production Press | 1,000 kg - 100,000+ kg | 100 - 10,000+ tons | Heavy manufacturing (e.g., forging, stamping) |

Need Help Selecting the Right Hydraulic Press for Your Lab or Workshop?

Choosing the correct press is critical for safety and efficiency. The weight and power of the machine must perfectly match your specific application, whether it's for delicate sample preparation or robust material testing.

KINTEK specializes in high-quality lab equipment, including hydraulic presses tailored to your needs. We can help you navigate the specifications to find a press that offers the ideal balance of power, precision, and size for your laboratory or workshop.

Contact our experts today for a personalized consultation and discover how the right hydraulic press can enhance your workflow and results.

#ContactForm to get a recommendation and quote!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples