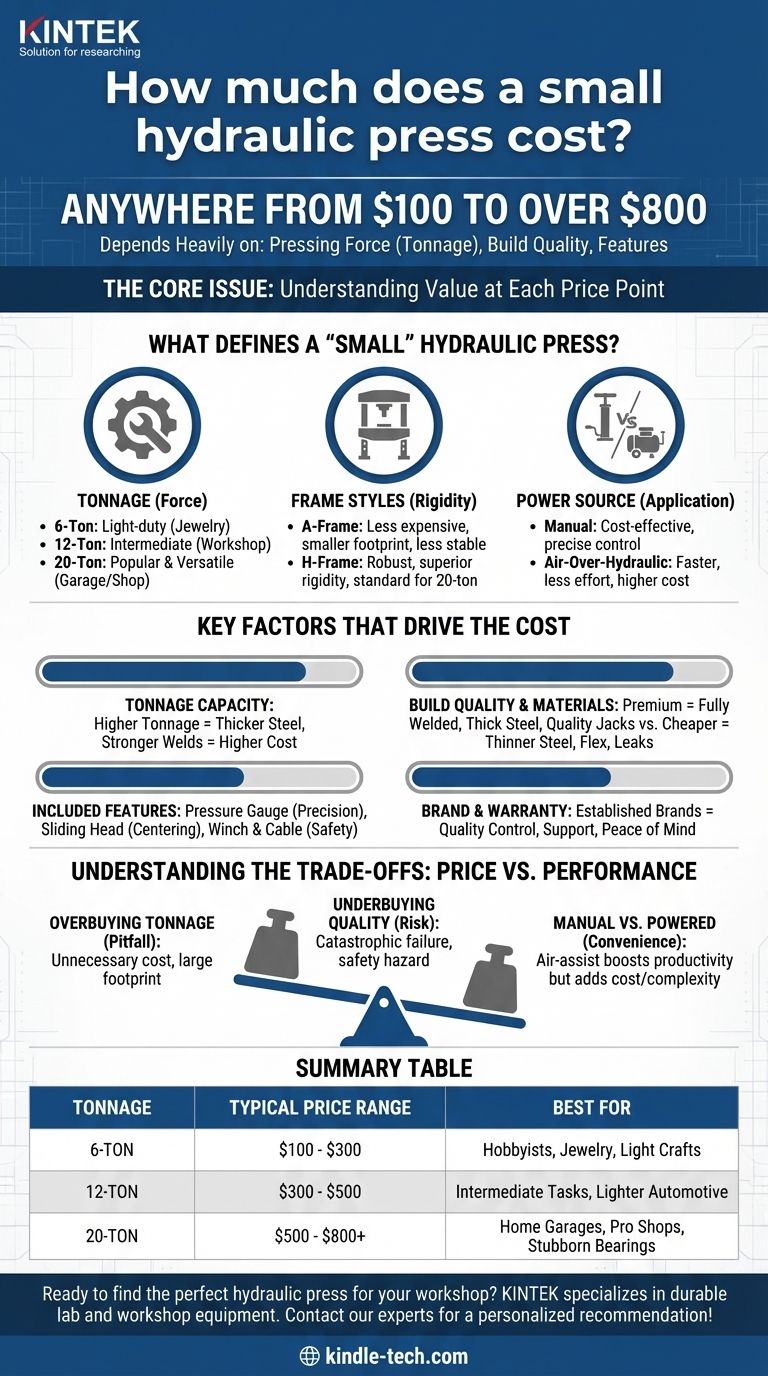

In short, a small hydraulic press can cost anywhere from $100 to over $800. The final price depends heavily on its pressing force (tonnage), build quality, and features. A basic 6-ton benchtop model for hobbyist use sits at the low end, while a robust 20-ton H-frame shop press with premium features will be at the higher end of that range.

The core issue isn't just the initial cost, but understanding what you are paying for at each price point. The key factors influencing price are tonnage, frame construction, and power source, which directly translate to the press's safety, capability, and ease of use.

What Defines a "Small" Hydraulic Press?

Before analyzing cost, it's crucial to understand the key characteristics of presses in this category. They are typically defined by their tonnage, frame style, and how they are powered.

Tonnage: The Primary Metric

Tonnage measures the maximum force the press can exert. For small presses, the most common ratings are 6, 12, and 20 tons.

A 6-ton press is often a small, benchtop unit, ideal for very light-duty tasks like jewelry making or installing small bushings.

A 12-ton press is a significant step up, usually an A-frame or light H-frame design. It can handle many common workshop tasks but may struggle with larger automotive components.

The 20-ton press is the most popular and versatile choice for home garages and small professional shops, capable of handling stubborn bearings, U-joints, and ball joints.

Frame Styles: H-Frame vs. A-Frame

The frame is the backbone of the press, and its design dictates rigidity and stability under load.

A-frame presses are typically less expensive and have a smaller footprint. They are suitable for lighter tasks but can flex or "walk" under maximum load, which can be a safety concern.

H-frame presses are constructed with heavier, thicker steel beams, offering superior rigidity and stability. This robust design is standard for 20-ton models and is essential for safely handling high-pressure jobs.

Power Source: Manual vs. Air-Over-Hydraulic

The power source determines how you apply force.

Manual hydraulic presses use a simple hand-pump jack, similar to a bottle jack. This is the most common and cost-effective option, offering good control over the pressing action.

Air-over-hydraulic presses (or pneumatic presses) add an air-powered motor to the hydraulic jack. This allows you to operate the press with a foot pedal or lever, which is much faster and requires less physical effort, especially for repetitive tasks.

Key Factors That Drive the Cost

The price of a press is a direct reflection of its engineering and features. Understanding these factors will help you decipher why two 20-ton presses can have vastly different price tags.

Tonnage Capacity

This is the most straightforward cost factor. As tonnage increases, the frame must be built with thicker steel and stronger welds to handle the force, directly increasing the manufacturing cost.

Build Quality and Materials

A cheaper press often uses thinner gauge steel for the frame, which can dangerously flex or fail under load. Premium presses feature fully welded joints, thicker steel, and higher-quality hydraulic jacks that are less prone to leaking or failing.

Included Features

Advanced features add to the cost but can dramatically improve usability and safety.

A pressure gauge is a critical feature, allowing you to apply precise force instead of just guessing. A sliding press head (ram) lets you center the force over off-center workpieces. A winch and cable system makes it easier and safer to adjust the height of the heavy press bed.

Brand and Warranty

Established brands often have better quality control, customer support, and more reliable warranties. While a generic import may be cheaper initially, a reputable brand can offer more peace of mind and long-term value.

Understanding the Trade-offs: Price vs. Performance

Making an informed decision means balancing your budget with your actual needs and being aware of the potential pitfalls.

The Pitfall of "Overbuying" Tonnage

It's tempting to buy the most powerful press you can afford, but a 50-ton press is often unnecessary for a small shop. It has a much larger footprint and a significantly higher cost, offering no real benefit if your work only requires 15 tons of force.

The Risk of "Underbuying" on Quality

This is the more dangerous mistake. A low-cost press might save you money upfront, but a frame that flexes, a jack that leaks, or welds that crack under load can lead to catastrophic failure and serious injury. Safety should always be the primary consideration.

Manual vs. Powered: Convenience at a Cost

An air-assisted press can be a game-changer for productivity, but it adds to the initial cost and complexity. It also requires a suitably sized air compressor, which is an additional expense if you don't already own one.

Making the Right Choice for Your Goal

Select a press based on the specific tasks you need to accomplish, not just the price tag.

- If your primary focus is occasional hobbyist work (e.g., small bearings, crafting): A 6-ton benchtop or 12-ton A-frame press offers sufficient power at a very low entry cost.

- If your primary focus is automotive repair or a versatile home workshop: A 20-ton H-frame press is the industry standard, providing the best balance of capability, safety, and value.

- If your primary focus is productivity and repetitive tasks: Investing in a model with a pressure gauge and air-over-hydraulic assist will significantly speed up your workflow.

Choosing the right press means matching its capabilities not just to your budget, but to the specific demands of your work.

Summary Table:

| Tonnage | Typical Price Range | Best For |

|---|---|---|

| 6-Ton | $100 - $300 | Hobbyists, jewelry making, light crafts |

| 12-Ton | $300 - $500 | Intermediate tasks, lighter automotive work |

| 20-Ton | $500 - $800+ | Home garages, professional shops, stubborn bearings |

Ready to find the perfect hydraulic press for your workshop? KINTEK specializes in durable lab and workshop equipment, including hydraulic presses designed for safety and performance. Whether you're a hobbyist or a professional, our experts can help you select the right model for your needs and budget. Contact us today for a personalized recommendation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy