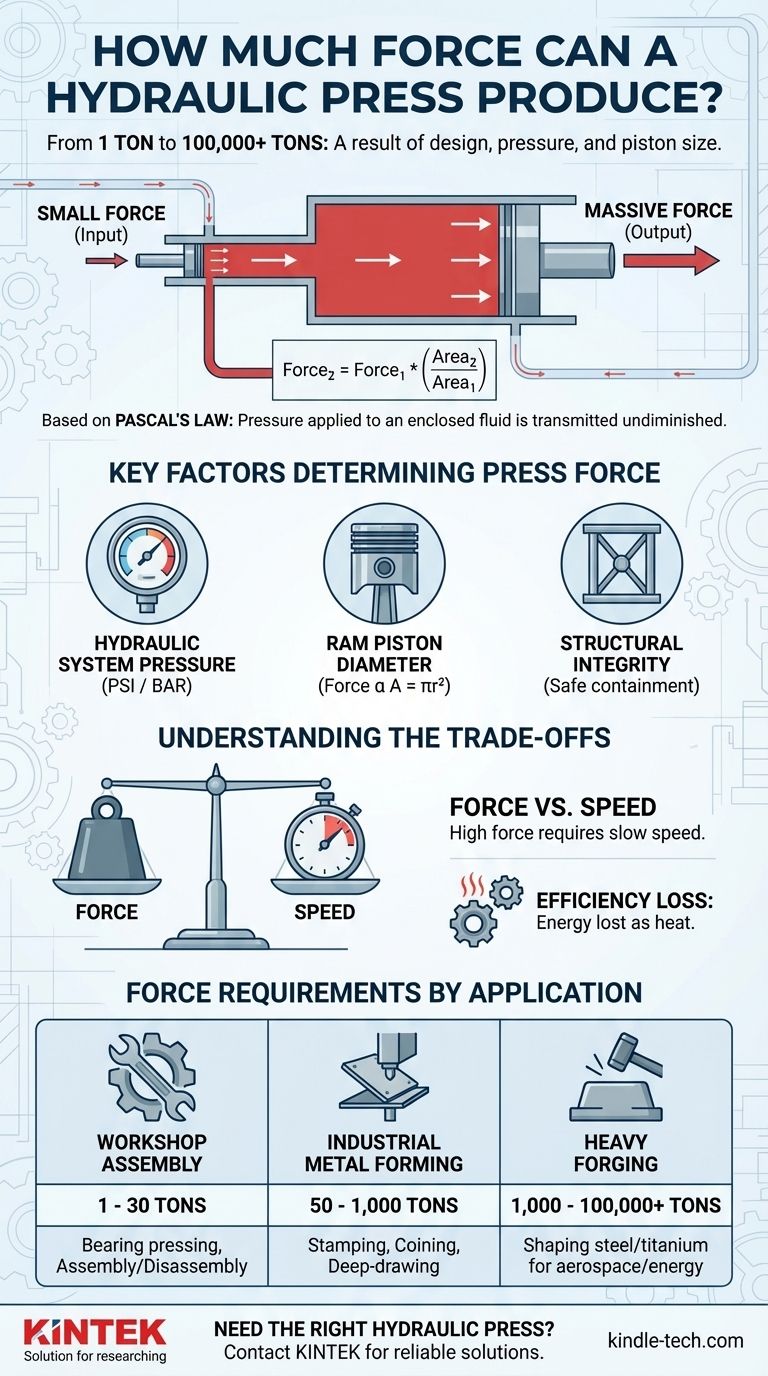

At its core, a hydraulic press can produce a force ranging from just one ton for a small workshop press to over 100,000 tons for massive industrial forging machines. The exact amount of force is not a single number but is a direct result of the system's design, specifically the hydraulic pressure and the size of the piston it acts upon. This force can be precisely managed using components like proportional control valves.

The immense power of a hydraulic press comes from a simple principle of physics: force multiplication. It doesn't create energy, but rather trades a small force applied over a large distance for a massive force applied over a very short distance.

The Principle of Force Multiplication

To understand how a hydraulic press generates such extreme force, you must first understand the fundamental law that governs it.

Introducing Pascal's Law

The entire operation is based on Pascal's Law. This principle states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, pressure applied at one point in a sealed hydraulic system is felt equally everywhere else within that system.

The Critical Role of Piston Area

The genius of the hydraulic press is in how it uses Pascal's Law across two pistons of different sizes.

A small initial force is applied to a small piston (the input), which creates pressure in the hydraulic fluid. This same pressure then acts on a much larger piston (the output or ram), but because the larger piston has a much greater surface area, the resulting force is multiplied proportionally.

The formula is straightforward: Force₂ = Force₁ * (Area₂ / Area₁). If the output piston has 100 times the area of the input piston, the output force will be 100 times the input force.

An Analogy: The Hydraulic Lever

Think of a hydraulic press as a fluid-based lever. With a mechanical lever, you apply a small force over a long distance at one end to lift a heavy object a short distance at the other.

A hydraulic system does the same. The small input piston must travel a long distance to displace enough fluid to move the large output piston a very short distance, but with incredible force.

Key Factors Determining Press Force

The theoretical maximum force of any given press is determined by three primary factors.

Hydraulic System Pressure

This is the amount of pressure the hydraulic pump can generate within the sealed fluid, often measured in pounds per square inch (PSI) or bars. Higher pressure translates directly to higher potential force for a piston of a given size.

Ram Piston Diameter

This is the single most significant factor in force multiplication. Because the surface area of a circle increases with the square of its radius (A = πr²), even a small increase in the output piston's diameter leads to a massive increase in its surface area and, therefore, its potential output force.

Structural Integrity

The theoretical force is meaningless if the machine's frame cannot withstand it. The press frame, cylinders, and seals must all be engineered to safely contain the immense forces being generated without deformation or failure.

Understanding the Trade-offs

The power of a hydraulic press does not come for free. There is a fundamental trade-off that is critical to understand.

The Force vs. Speed Relationship

The most significant trade-off is between force and speed. As explained by the "hydraulic lever" analogy, to achieve massive force multiplication, the large output ram will move very slowly.

Achieving high tonnage requires displacing a large volume of fluid, which takes time. You cannot have both extreme force and high speed simultaneously without an exceptionally powerful (and large) hydraulic pump and motor.

Efficiency and Energy Loss

While the underlying principle is simple, real-world systems are not 100% efficient. Energy is always lost, primarily as heat generated by the friction of the fluid moving through hoses, valves, and fittings. This means the actual output force will always be slightly less than the theoretical maximum.

How to Determine Your Force Requirement

The force you need is dictated entirely by your application.

- If your primary focus is workshop assembly/disassembly: For tasks like pressing bearings, bushings, or gears, a press in the 1-to-30-ton range is almost always sufficient.

- If your primary focus is industrial metal forming: For stamping, coining, or deep-drawing sheet metal, the required force depends on the material's type, thickness, and the complexity of the final part, often falling in the 50-to-1,000-ton range.

- If your primary focus is heavy forging: For shaping large steel or titanium ingots for aerospace or energy applications, you are in a specialized domain where forces are engineered to be in the thousands or tens of thousands of tons.

Understanding the principles of force multiplication empowers you to see beyond a simple number and evaluate a press based on the fundamental factors that truly define its capability.

Summary Table:

| Press Type | Typical Force Range | Common Applications |

|---|---|---|

| Workshop Press | 1 - 30 Tons | Bearing/bushing pressing, assembly/disassembly |

| Industrial Metal Forming Press | 50 - 1,000 Tons | Stamping, coining, deep-drawing sheet metal |

| Heavy Forging Press | 1,000 - 100,000+ Tons | Shaping large steel/titanium ingots for aerospace/energy |

Need the right hydraulic press for your lab or production line?

At KINTEK, we specialize in providing reliable lab equipment and consumables. Whether you need a precise workshop press for assembly tasks or are exploring industrial-scale solutions, our experts can help you select a hydraulic press that delivers the exact force and control your application requires.

Contact our team today to discuss your specific force requirements and discover the KINTEK advantage in performance and durability.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.