Porcelain is exceptionally resistant to high temperatures, a direct result of the intense heat required for its creation. A high-quality porcelain piece can typically withstand temperatures up to 2,550°F (1,400°C) without melting or losing its structural integrity. However, its true vulnerability is not the peak temperature, but the speed at which that temperature changes.

The most critical factor determining porcelain's performance under heat is not the maximum temperature it can endure, but its susceptibility to thermal shock. Sudden, uneven heating or cooling is far more likely to cause it to crack or shatter than a high, stable temperature.

Why Is Porcelain So Heat-Resistant?

The ability of porcelain to handle extreme heat is engineered into it during its manufacturing process. This isn't an accidental property; it's a core characteristic of the material.

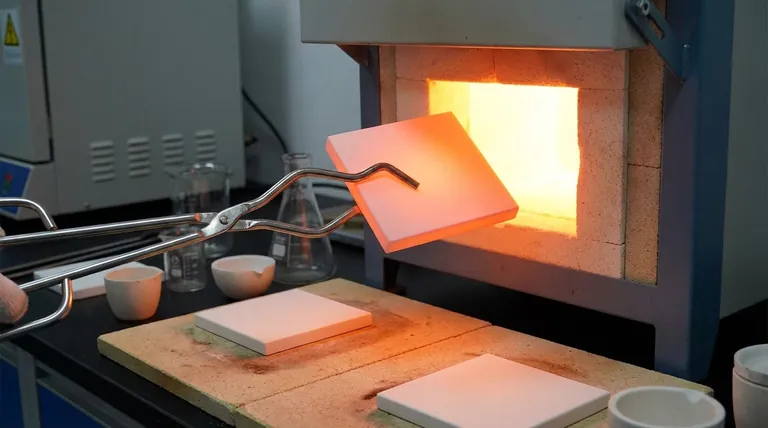

The Vitrification Process

Porcelain is fired in a kiln at extremely high temperatures, typically between 2,200°F and 2,600°F (1,200°C to 1,400°C). This intense heat causes the raw materials—kaolin, feldspar, and quartz—to fuse together into a glass-like, non-porous material. This process, called vitrification, gives porcelain its density, strength, and thermal stability.

A Dense, Stable Structure

Because it was born in fire, porcelain is chemically stable and inert at temperatures below its firing point. Its dense, vitrified structure has very few pores for water to penetrate, which prevents the cracking that can occur in other ceramics when trapped moisture turns to steam.

The Real Threat: Understanding Thermal Shock

While porcelain can handle a stable high temperature, it performs poorly against rapid temperature changes. This phenomenon is known as thermal shock, and it is the primary cause of heat-related failure.

What is Thermal Shock?

Thermal shock occurs when different parts of a single object expand or contract at different rates due to a sudden change in temperature. Imagine pouring boiling water into a cold, thick glass mug—the inner surface expands instantly while the outer surface remains cold and contracted. This internal stress can exceed the material's strength, causing a fracture.

How Thermal Shock Breaks Porcelain

Porcelain is a rigid, crystalline material. While very strong under compression, it is brittle and does not flex to accommodate the internal stresses created by rapid, uneven expansion or contraction. This stress concentrates around microscopic flaws, creating cracks that can propagate instantly, leading to a complete break.

Common Causes of Failure

The most common real-world scenarios for thermal shock include:

- Placing a cold porcelain dish from the refrigerator directly into a hot, preheated oven.

- Putting a hot porcelain dish onto a cold or wet surface, like a granite countertop.

- Pouring cold liquid into a very hot porcelain vessel.

- Exposing a piece to a direct, concentrated heat source, like a stovetop burner, which heats one area far more quickly than the rest.

Common Pitfalls and Considerations

Understanding the limitations of porcelain is just as important as knowing its strengths. Objectively, there are trade-offs to consider for any high-heat application.

Oven-Safe vs. Stovetop-Safe

These terms are not interchangeable. "Oven-safe" implies the porcelain can handle the gradual, even heating of an oven environment. Most high-quality porcelain is oven-safe. "Stovetop-safe" or "flameproof" is a much higher standard, requiring a special composition (like cordierite) that can withstand the intense, direct heat from a burner. Standard porcelain will almost always crack on a stovetop.

The Glaze Can Be a Weak Point

The glaze on a porcelain piece can have a slightly different coefficient of thermal expansion than the porcelain body itself. Over many cycles of heating and cooling, this mismatch can cause a network of fine cracks in the glaze, known as crazing. While this doesn't mean the piece has failed, it can compromise the surface and aesthetics.

Not All "Porcelain" Is Created Equal

The term "porcelain" can be used loosely for marketing. True, high-fired porcelain is significantly more durable and heat-resistant than lower-fired ceramics like stoneware or earthenware. For any application where heat tolerance is critical, you must ensure you are using true, high-quality porcelain.

Making the Right Choice for Your Application

To use porcelain effectively, match its properties to your specific goal.

- If your primary focus is oven baking: Always place room-temperature porcelain into a cool oven and let them preheat together for the most gradual temperature change.

- If your primary focus is lab work or industrial use: Use only technical-grade porcelain crucibles specifically designed for direct flame contact and rapid thermal cycling.

- If your primary focus is preventing breakage in any situation: Never subject porcelain to extreme and sudden temperature shifts, as this is its primary point of failure.

By understanding that the rate of temperature change is the true enemy, you can confidently leverage porcelain's remarkable heat resistance.

Summary Table:

| Property | Typical Range / Key Point |

|---|---|

| Maximum Withstand Temperature | Up to 2,550°F (1,400°C) |

| Firing Temperature | 2,200°F - 2,600°F (1,200°C - 1,400°C) |

| Primary Vulnerability | Thermal Shock (Sudden temperature changes) |

| Oven-Safe | Yes, with gradual heating |

| Stovetop/Flameproof | No, unless specially formulated (e.g., cordierite) |

Need reliable, high-temperature lab equipment?

Understanding material limits like porcelain's is crucial for successful experiments and processes. At KINTEK, we specialize in supplying robust laboratory equipment and consumables, including high-temperature furnaces and technical ceramics designed to withstand thermal cycling.

Let our expertise help you select the right tools for your specific application. Contact our specialists today to discuss your lab's needs and ensure your operations run safely and efficiently.

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is the function of alumina setter plates for LATP? Protect Material Purity & Prevent Adhesion

- What are the typical properties of high-alumina (Al2O3) refractories? Enhance Performance with High-Temp Resilience

- What are the process advantages of selecting an alumina plate for CuO nanofilm synthesis? Achieve Superior Purity

- What are the high temperature properties of alumina? Discover Its Stability, Strength, and Limits

- What is the most common industrial ceramic? Discover Why Alumina Dominates Countless Applications