At its core, electrolyte management is a task of preventative maintenance. The primary strategy is the periodic replacement of the electrolyte, with the frequency determined by how heavily the system is used. This prevents the inevitable accumulation of chemical impurities that degrade performance and can damage system components.

Think of an electrolyte not as a permanent fluid, but as a consumable component like the oil in an engine. Its chemical properties change with use, and failing to refresh it leads to diminished performance and eventual system failure.

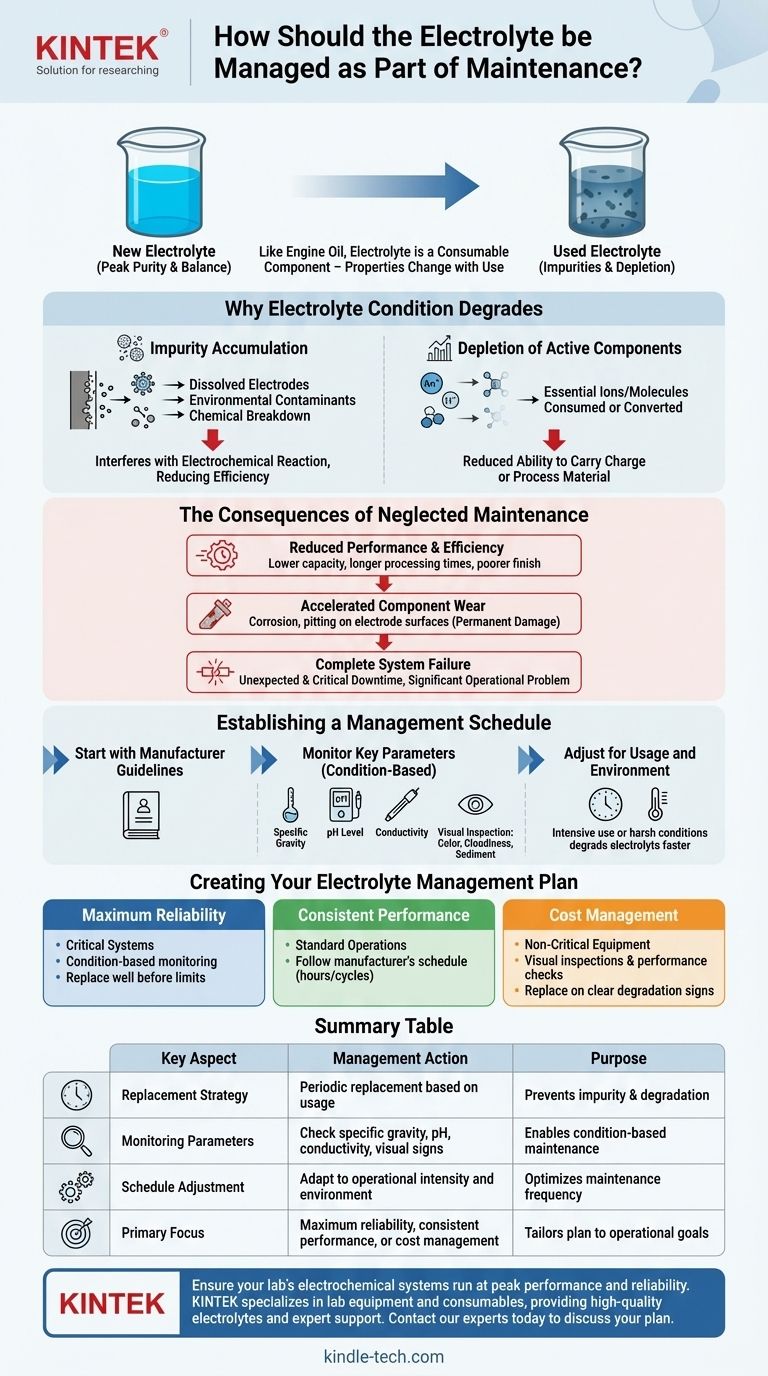

Why Electrolyte Condition Degrades

Understanding the mechanisms of degradation is crucial for effective management. An electrolyte in a new system is at its peak purity and chemical balance, but this state is temporary.

The Problem of Impurity Accumulation

With every operational cycle, microscopic particles and unwanted ions are introduced into the solution. These impurities can come from the slow dissolution of electrodes, environmental contaminants, or the chemical breakdown of the electrolyte itself.

This contamination directly interferes with the intended electrochemical reaction, reducing the system's efficiency.

Depletion of Active Components

The electrolyte contains specific ions and molecules that are essential for the system to function. Over time and through repeated use, these active components are consumed or converted into less effective forms.

As their concentration drops, the electrolyte's ability to perform its function—whether it's carrying a charge or processing a material—is significantly reduced.

The Consequences of Neglected Maintenance

Postponing electrolyte maintenance is not a cost-saving measure. The consequences of running a system with a degraded electrolyte are often far more expensive than the maintenance itself.

Reduced Performance and Efficiency

The first and most noticeable symptom of a failing electrolyte is a drop in performance. For a battery, this may mean a lower capacity or inability to deliver high current. For an electropolishing system, it could mean longer processing times and a poorer finish.

Accelerated Component Wear

Impurities don't just hinder performance; they can actively damage the system. Contaminants can cause corrosion or pitting on sensitive electrode surfaces, leading to permanent damage that electrolyte replacement alone cannot fix.

Complete System Failure

In the final stages, a depleted and contaminated electrolyte will simply stop working. This can lead to unexpected and critical downtime, turning a manageable maintenance task into a significant operational problem.

Establishing a Management Schedule

The term "periodically" depends entirely on your specific system, usage patterns, and operating environment. A one-size-fits-all schedule does not exist.

Start with Manufacturer Guidelines

The system's manufacturer provides the most reliable starting point. Their recommendations are based on extensive testing and are designed to ensure optimal longevity and performance.

Monitor Key Parameters

For more precise control, you can move beyond time-based schedules to condition-based monitoring. Depending on the system, this can involve measuring properties like:

- Specific Gravity: Common in lead-acid batteries to check the state of charge and health.

- pH Level: Crucial in many chemical baths where acidity or alkalinity is key.

- Conductivity: A direct measure of the electrolyte's ability to carry a current.

- Visual Inspection: Look for changes in color, cloudiness, or the formation of sediment.

Adjust for Usage and Environment

A system running 24/7 in a high-temperature environment will degrade its electrolyte far faster than one used intermittently in a climate-controlled room. Always adjust your schedule based on the operational intensity and environmental stressors.

Creating Your Electrolyte Management Plan

Use the following guidelines to establish a strategy that matches your operational needs.

- If your primary focus is maximum reliability for critical systems: Implement a condition-based monitoring program and replace the electrolyte well before it reaches the manufacturer's stated limits.

- If your primary focus is consistent performance in standard operations: Follow the manufacturer's recommended replacement schedule based on hours of use or operational cycles.

- If your primary focus is cost management for non-critical equipment: Rely on regular visual inspections and performance checks, replacing the electrolyte only when clear signs of degradation appear.

Proactive electrolyte management is the key to ensuring the reliability and longevity of your electrochemical system.

Summary Table:

| Key Aspect | Management Action | Purpose |

|---|---|---|

| Replacement Strategy | Periodic replacement based on usage | Prevents impurity accumulation and component degradation |

| Monitoring Parameters | Check specific gravity, pH, conductivity, visual signs | Enables condition-based maintenance for precise control |

| Schedule Adjustment | Adapt to operational intensity and environment | Optimizes maintenance frequency for cost and reliability |

| Primary Focus | Maximum reliability, consistent performance, or cost management | Tailors the maintenance plan to specific operational goals |

Ensure your lab's electrochemical systems run at peak performance and reliability. Proper electrolyte management is essential for preventing costly downtime and component damage. KINTEK specializes in lab equipment and consumables, providing the high-quality electrolytes and expert support your laboratory needs.

Contact our experts today to discuss your electrolyte management plan and discover how we can help you maintain optimal system health.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- What are the advantages of using a PTFE deposition tank for EPD? Achieve Unmatched Coating Precision on Stainless Steel

- What precautions should be taken regarding temperature when using an all-PTFE electrolytic cell? Ensure Safe & Accurate Experiments

- What role does a two-electrode electrochemical reactor play in TiO2 growth? Achieve Ordered Nanostructures Today

- What functions do electrolytic cells perform in PEC water splitting? Optimize Your Photoelectrochemical Research

- What are the primary functions of a high-performance electrolytic cell in the eCO2R process? Optimize Your Lab Results