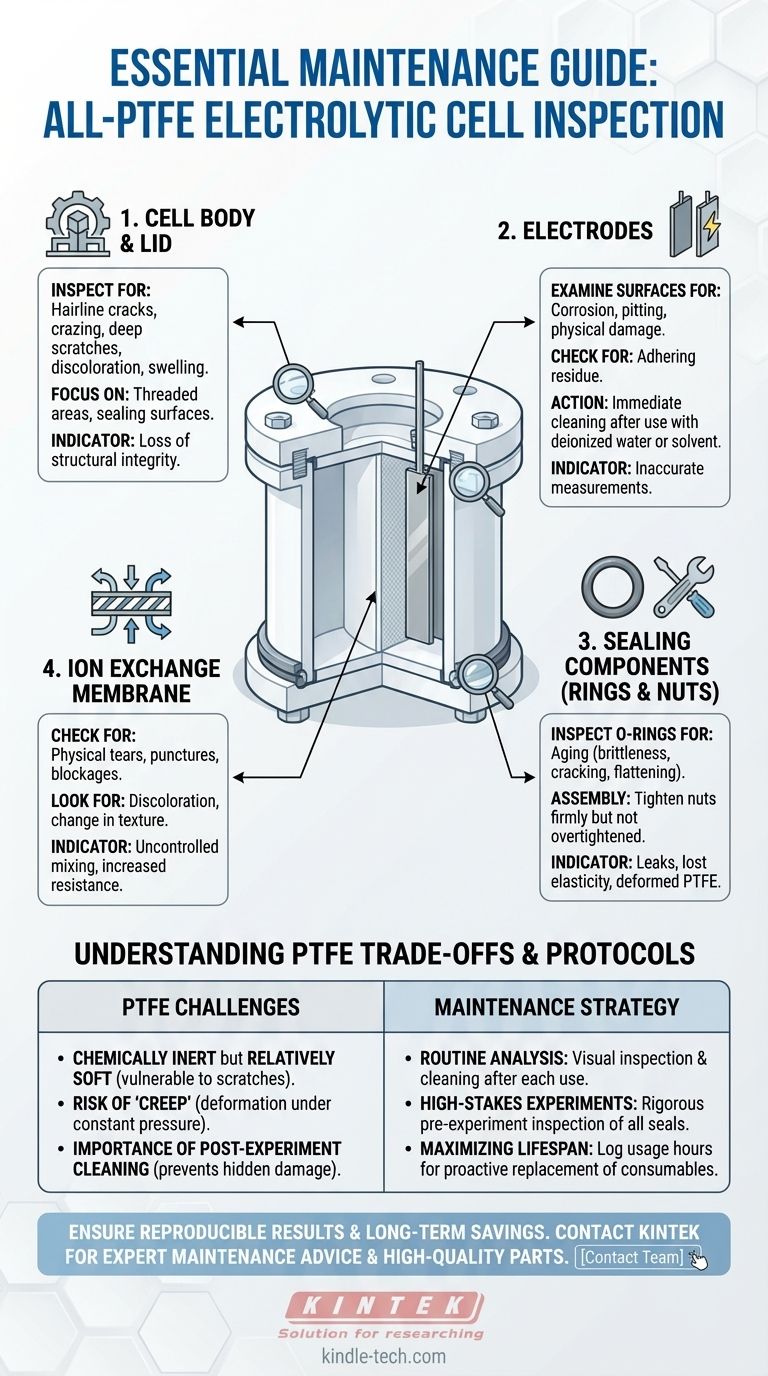

To properly maintain an all-PTFE electrolytic cell, you must regularly inspect four critical components: the cell body itself, the electrodes, the sealing rings, and the ion exchange membrane. Any signs of cracking, corrosion, aging, or leakage are indicators that a component needs immediate replacement to ensure the integrity of your experiments.

The core principle of maintaining a PTFE cell is not just spotting damage, but preventing the two primary modes of failure: chemical leaks and sample contamination. A disciplined inspection routine is the most effective way to protect your results and extend the life of your equipment.

A Systematic Inspection Checklist

A thorough maintenance process moves from the general structure to the most sensitive functional parts. Each component has unique failure points that demand specific attention.

The Cell Body and Lid

The PTFE body provides the inert environment for your reaction. Its primary failure mode is a loss of structural integrity.

Visually inspect the cell body and lid for any hairline cracks, crazing, or deep scratches. Pay close attention to threaded areas and sealing surfaces where mechanical stress is highest.

Also, look for any discoloration or swelling of the PTFE material. While highly resistant, prolonged exposure to aggressive chemicals at high temperatures can eventually degrade the polymer.

The Electrodes

Electrodes are the active heart of the cell, and their surface condition directly impacts experimental performance and reproducibility.

Examine the electrode surfaces for signs of corrosion, pitting, or physical damage. A compromised surface can lead to inaccurate measurements and unwanted side reactions.

After each use, check for any adhering residue. Immediate cleaning with deionized water or a suitable solvent is critical to prevent buildup that can passivate the electrode surface.

Sealing Components (Rings and Nuts)

Seals are the most common point of failure in any fluidic system. In a PTFE cell, this is where leaks are most likely to originate.

Carefully inspect all sealing rings (O-rings) for signs of aging, such as brittleness, cracking, or flattening. A seal that has lost its elasticity will not provide a reliable barrier.

When assembling, ensure the nuts are tightened to provide a firm seal but are not overtightened. Excessive force can deform the relatively soft PTFE components, leading to leaks over time.

The Ion Exchange Membrane

The membrane selectively controls ion transport between cell compartments. Its condition is paramount for the cell to function as designed.

Check the membrane for any physical tears, punctures, or blockages. A damaged membrane will allow uncontrolled mixing of anolyte and catholyte, invalidating the experiment.

Discoloration or a change in texture can indicate membrane aging or fouling. This can impede ion flow and increase cell resistance, skewing electrochemical data.

Understanding the Trade-offs of PTFE

While PTFE is chosen for its superior chemical resistance, its physical properties introduce specific maintenance challenges. Understanding these trade-offs is key to preventing problems.

Chemical Inertness vs. Physical Vulnerability

PTFE is one of the most chemically inert polymers available, making it ideal for corrosive environments.

However, it is also a relatively soft material. It can be easily scratched or gouged by sharp tools or abrasive cleaning methods, creating potential sites for contamination or seal failure.

The Risk of "Creep" and Deformation

A key characteristic of PTFE is its tendency to "creep," or slowly deform over time when under constant pressure.

This means that areas under compression, such as the sealing surfaces pressed by nuts, can permanently deform. This can make achieving a reliable seal more difficult over the cell's lifespan, necessitating the eventual replacement of major components.

The Importance of Post-Experiment Protocol

The references rightly emphasize cleaning the cell immediately after each experiment.

Leaving chemical residues to dry can make them significantly harder to remove. More importantly, this residue can hide underlying damage like small cracks or corrosion on an electrode, preventing you from catching a problem early.

Making the Right Choice for Your Goal

Your maintenance schedule should reflect the demands of your work. A routine check is always necessary, but its intensity can vary based on your experimental goals.

- If your primary focus is routine analysis: A thorough visual inspection and cleaning after each use is sufficient to maintain performance.

- If your primary focus is high-stakes or long-duration experiments: Conduct a more rigorous pre-experiment inspection, potentially disassembling and checking all sealing rings to prevent costly mid-run failures.

- If your primary focus is maximizing the cell's lifespan: Implement a log to track usage hours and cycles for consumable parts like sealing rings and membranes, allowing you to replace them proactively before they fail.

Ultimately, a proactive and systematic approach to maintenance is the key to ensuring your electrolytic cell remains a reliable and precise scientific instrument.

Summary Table:

| Component | Key Inspection Points | Failure Indicators |

|---|---|---|

| Cell Body & Lid | Structural integrity, sealing surfaces | Cracks, crazing, discoloration, swelling |

| Electrodes | Surface condition, residue | Corrosion, pitting, physical damage, buildup |

| Sealing Rings & Nuts | Elasticity, compression | Brittleness, cracking, deformation, leaks |

| Ion Exchange Membrane | Physical integrity, surface condition | Tears, punctures, blockages, discoloration |

Ensure your experiments are never compromised by equipment failure. A well-maintained PTFE electrolytic cell is critical for reproducible results and long-term cost savings. KINTEK specializes in high-quality lab equipment and consumables, including electrolytic cells and their components. Our experts can help you establish a proactive maintenance routine or provide the reliable replacement parts you need. Contact our team today to discuss your specific laboratory requirements and keep your research running smoothly.

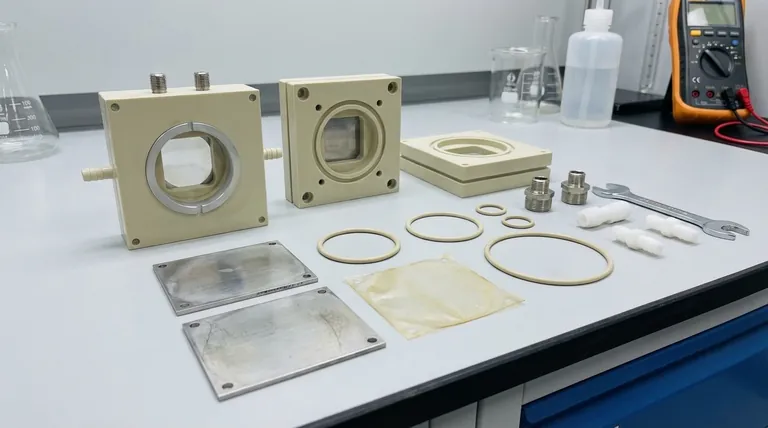

Visual Guide

Related Products

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- Double-Layer Water Bath Electrolytic Electrochemical Cell

People Also Ask

- What precautions should be taken regarding temperature when using an all-PTFE electrolytic cell? Ensure Safe & Accurate Experiments

- What are the advantages of using a PTFE deposition tank for EPD? Achieve Unmatched Coating Precision on Stainless Steel

- What are the primary functions of a high-performance electrolytic cell in the eCO2R process? Optimize Your Lab Results

- What is the purpose of using a frit glass tube in a three-electrode cell? Enhance Vanadium Redox Testing Accuracy

- What role does a two-electrode electrochemical reactor play in TiO2 growth? Achieve Ordered Nanostructures Today